Branch pipe assembly type prefabricating installation construction method for building pipeline clamp connection drainage system

A pipe clamp and drainage system technology, which is applied in indoor sanitary pipe installations, pipes/pipe joints/fittings, buildings, etc., can solve the difficulty of increasing project progress and cost control, unfavorable pipe system management, and difficult material system prediction Problems such as configuration and configuration can be avoided to avoid repeated use, facilitate system management, and be easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

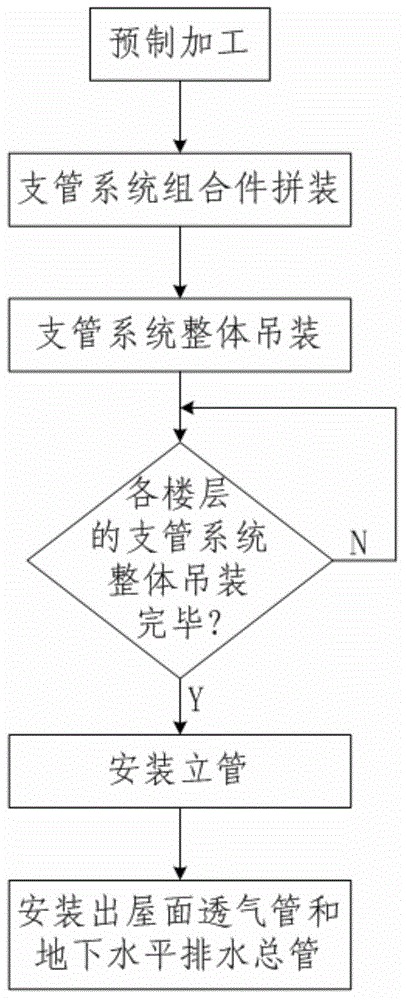

[0042] like figure 1 As shown, the construction method of the present invention for the pre-installation and installation of the combination of the branch pipes of the construction pipeline clamp connection drainage system includes the following steps:

[0043] Step 1. Prefabrication: According to the pre-designed branch pipe system diagram and according to the conventional prefabrication method, prefabricate the multiple branch pipe system assemblies assembled to form the branch pipe system;

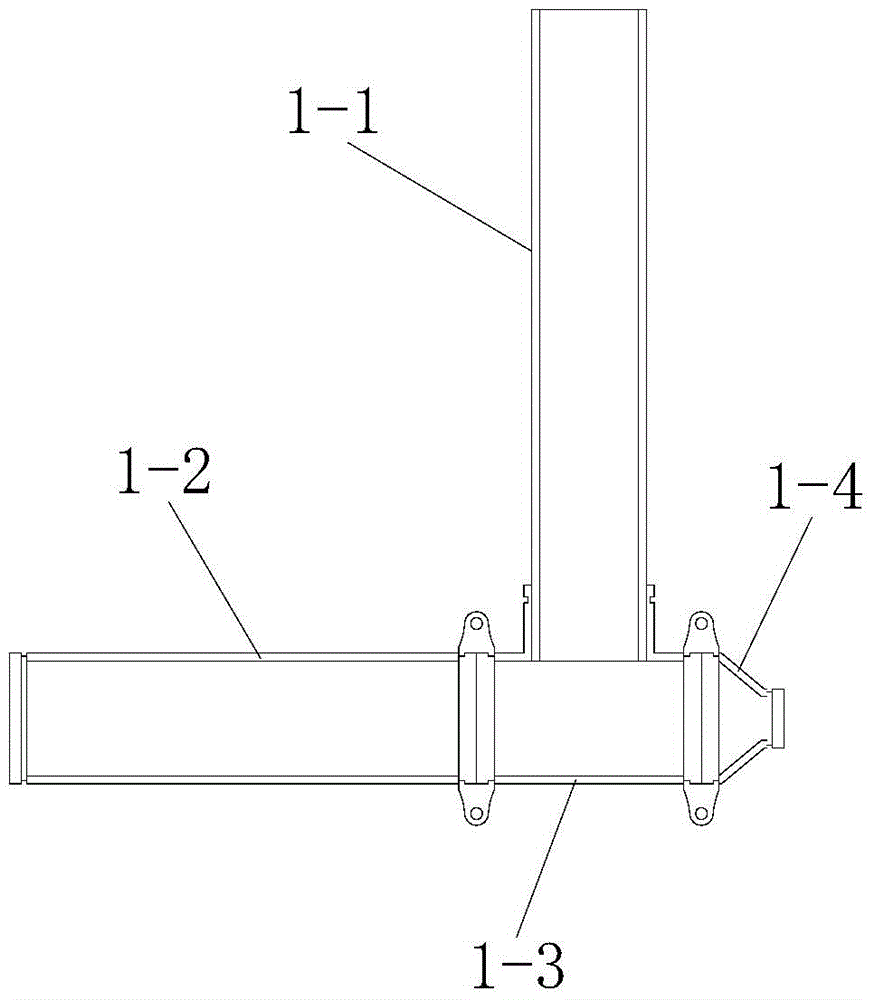

[0044] Step 2. Assembly of branch pipe system components: such as Figure 5 As shown, according to the pre-designed branch pipe system diagram, a plurality of branch pipe system assemblies constituting the branch pipe system are sequentially connected into one through the clamp 6;

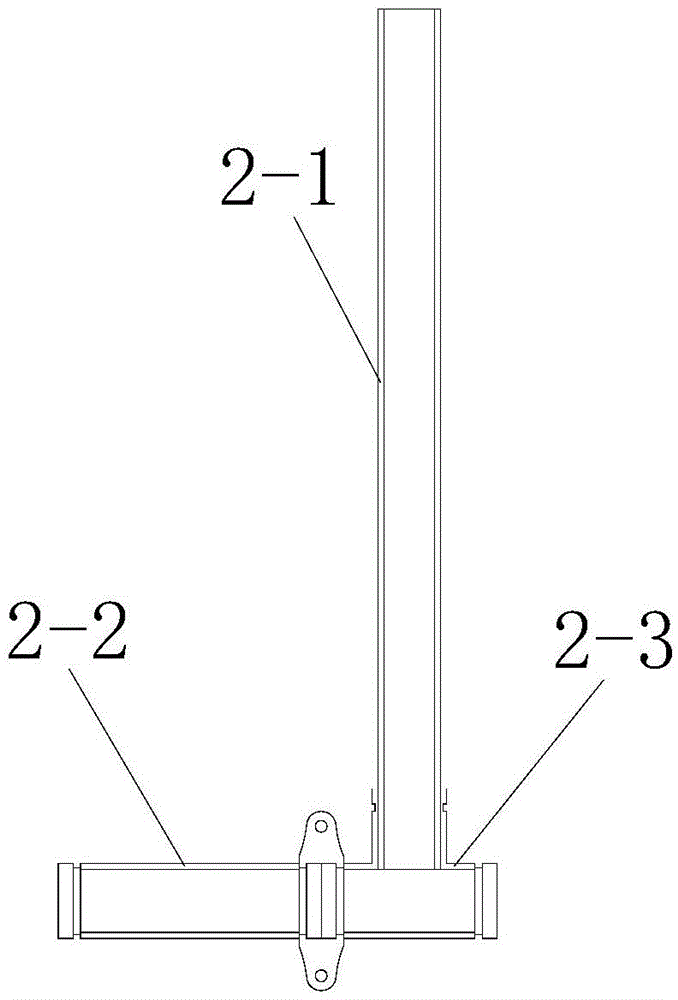

[0045] Step 3. The overall hoisting of the branch pipe system: such as Image 6 and Figure 7 As shown, the steel wire rope 7 is passed through the reserved holes in the floor 5 and fixed on the branch pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com