Garbage incinerator

A waste incinerator and furnace technology, which is applied in incinerators, combustion methods, combustion types, etc., can solve problems such as affecting the effect of waste incineration, high requirements for waste pretreatment, and unstable temperature, and achieve volume reduction, increase in temperature, and The effect of increasing dwell time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

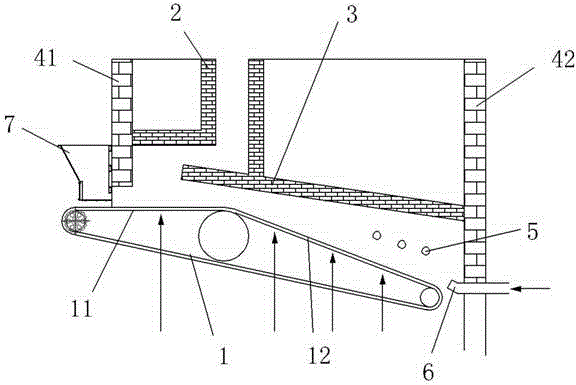

[0014] Such as figure 1 As shown, a garbage incinerator includes a chain grate 1, a feed port 7, an L-shaped front arch 2 and an inclined rear arch 3, the L-shaped front arch 2 extends from the furnace front wall 41 to the furnace, and the inclined rear arch 2 The arch 3 extends upwardly from the bottom of the rear wall 42 of the furnace, and the upper end of the inclined rear arch 3 is lower than the height of the horizontal section of the L-shaped front arch 2. It is characterized in that: the upper end of the inclined rear arch 3 extends to the L-shaped front Below the horizontal section of the arch 2, the chai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com