Wireless vibration monitoring system applied to auxiliary machine of thermal power plant and provided with self power generation device

A vibration monitoring system, a technology for thermal power plants, applied in generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, measuring devices, etc., can solve the problems of poor monitoring accuracy, low automation, and high cost , to reduce the number of failures, improve production efficiency, and improve reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with figures and specific embodiments.

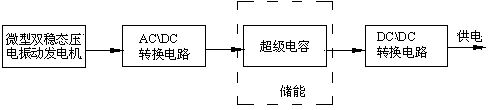

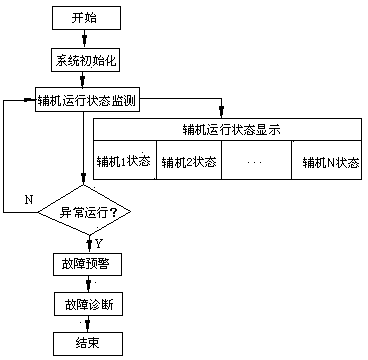

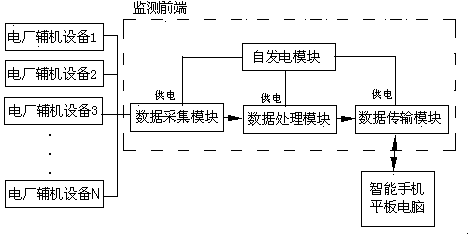

[0018] figure 1 It is the overall block diagram of the auxiliary equipment monitoring system of the thermal power plant. Considering the poor working environment, large quantity and wide distribution of auxiliary equipment, the system has a self-power supply device, which can convert the vibration energy in the environment into electrical energy and provide power for the front end of the monitoring system. At the same time, modern wireless communication technology using Bluetooth interface and Wi-Fi interface can quickly transmit the vibration signal of auxiliary equipment to the monitoring center. Technicians can use smart phones or tablet computers to browse the vibration monitoring information on site, in the monitoring center or wherever there is a network, and get the fault warning information at the first time, providing valuable time for rapid fault diag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com