Method and equipment for evaluating technological property of bolt installation

A technology for installation process and evaluation of equipment, applied in the direction of torque/torsional force measurement during tightening, which can solve problems such as taking longer time, bolts every one year or even less than half a year, and bolts being prone to breakage, so as to reduce the number of failures and The effect of downtime, expanding after-sales service, and improving market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] There are many reasons for bolt fracture, and the bolt fracture characteristics of different models and different positions are different. It is necessary to find out the root cause of the fracture, and then replace the broken bolt with the correct installation process, in order to achieve a reasonable bolt. maintain.

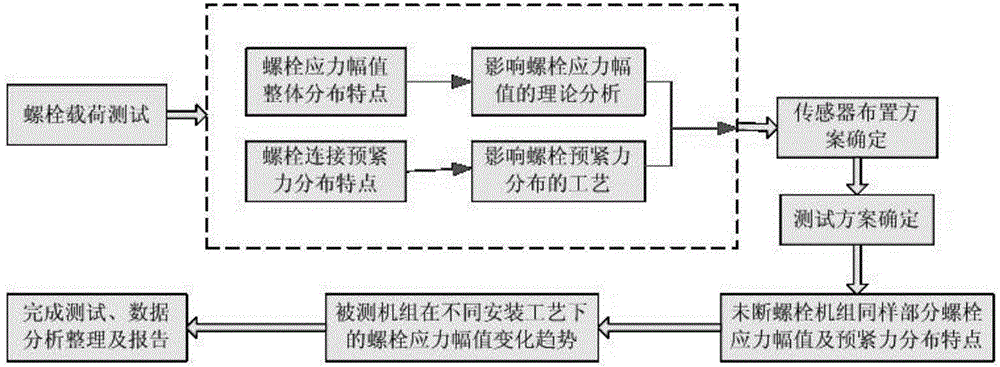

[0027] Please refer to figure 1 As shown, a bolt installation process performance evaluation method includes the following steps:

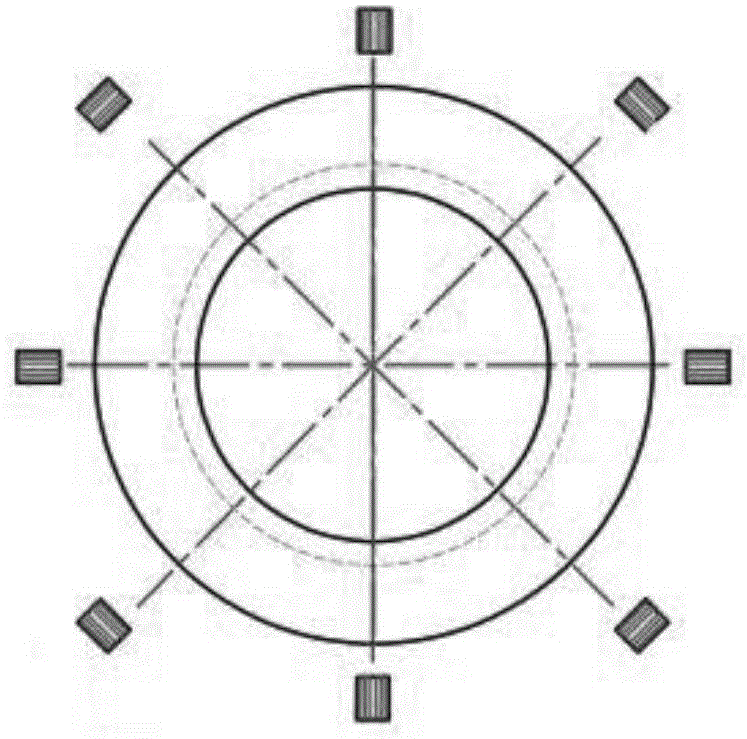

[0028] A. Determine the tightening sequence of the bolts on the flange surface;

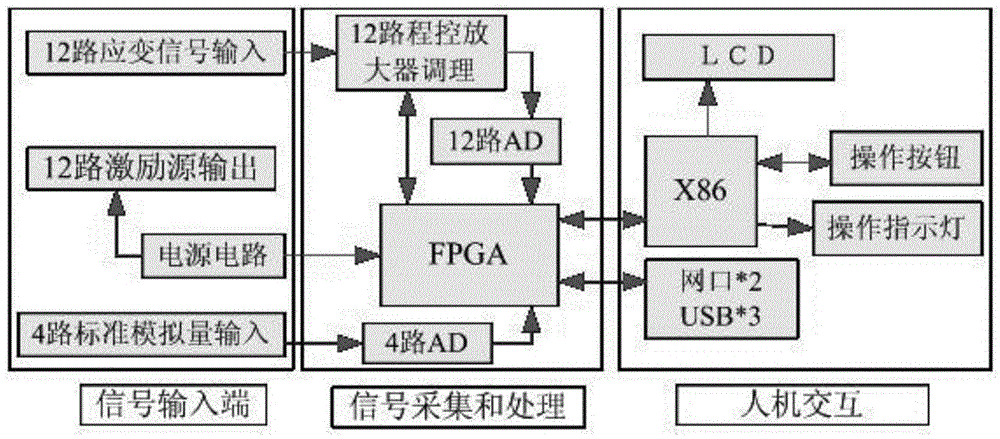

[0029] B. While tightening the bolts, a gasket pressure sensor is installed between the flange surface and the connecting bolts. After the bolts are tightened, the distribution of the bolt pretightening force on the flange circumferential end surface is measured by the gasket pressure sensor;

[0030] C. Apply a certain working load to the bolts, and test the fluctuation interval F of the real-time total tension of the bolts under different w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com