Method for evaluating insulation of crosslinked polyethylene medium-voltage cable through polarization current

A technology of cross-linked polyethylene and polarized current, which is applied in the direction of testing dielectric strength, can solve the problems of staying, difficult power system promotion, and insufficient accuracy of monitoring results, and achieves non-destructive, sensitive reflection, and simple testing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0017] The embodiment of the method for evaluating the insulation of XLPE medium-voltage cables by using the polarization current method of the present invention includes the following steps:

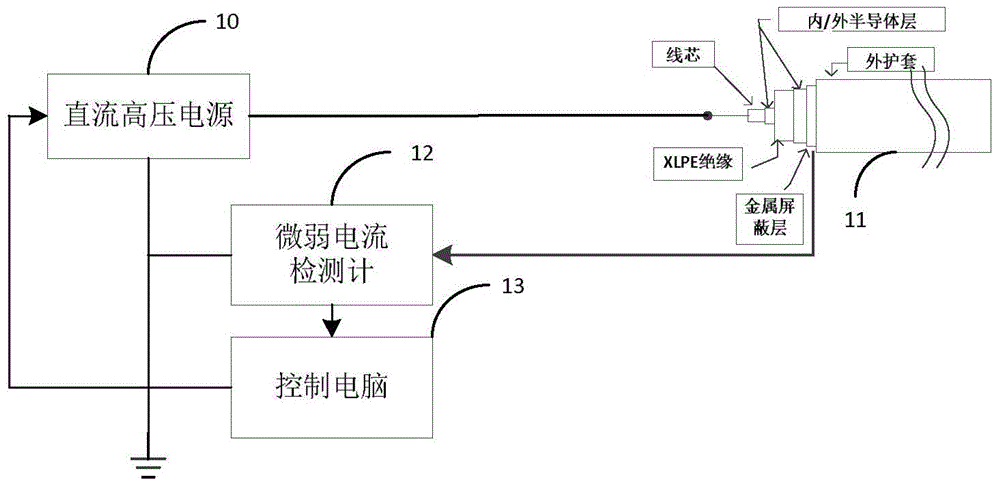

[0018] S1, directly connecting the high-voltage end and the low-voltage end of a DC high-voltage power supply 10 (greater than or equal to 1000V) to the wire core and the metal shielding layer of the cross-linked polyethylene medium-voltage cable sample 11, respectively, to generate cable polarization current;

[0019] The samples include new cables and cables with different aging degrees; S2, use a weak current detector 12 to connect to the low-voltage end of the loop to detect the polarization current of the cable sample 11, transmit it to and store the polarization current in real time through the computer 13 current data;

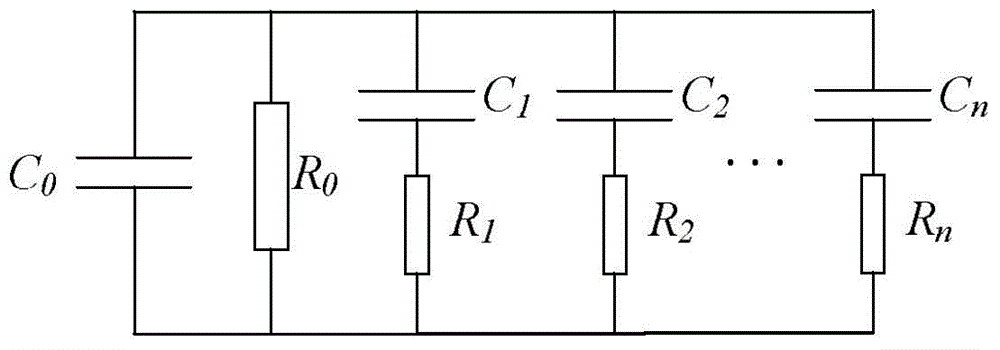

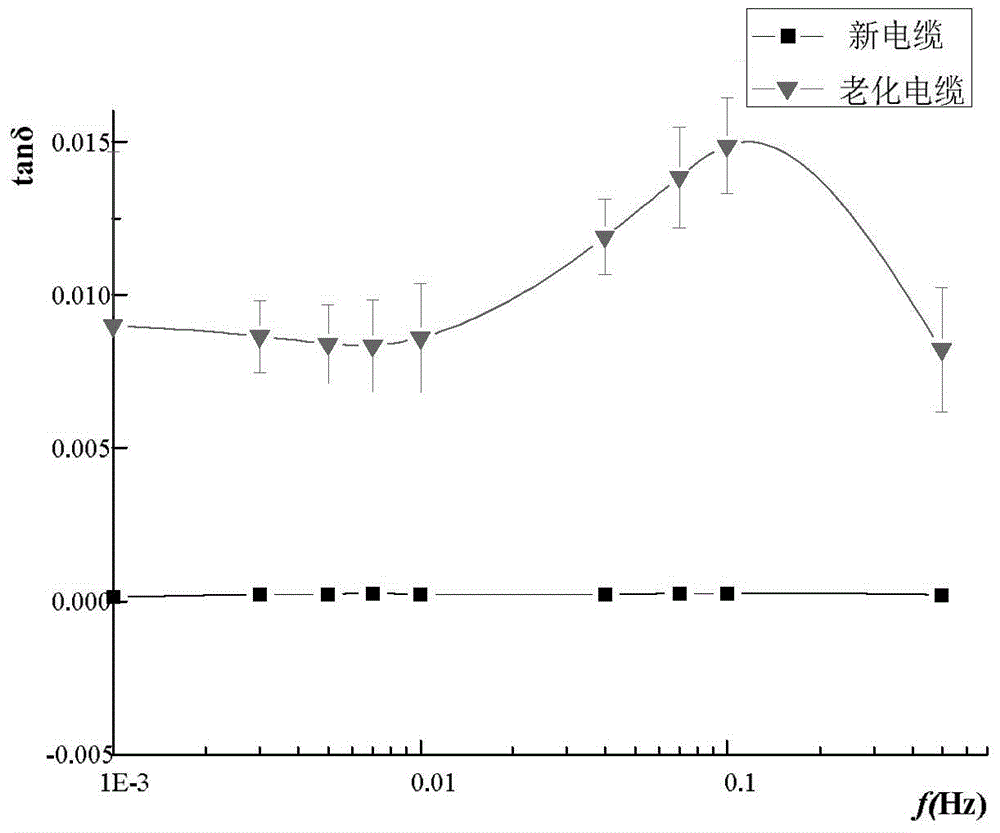

[0020] S3, use the exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com