Interactive welding joint groove graph drawing and parameter tagging method

A technology for welding joints and graphic drawing, which is used in electrical digital data processing, special data processing applications, instruments, etc., can solve problems such as low efficiency, information isolation, and distortion, and achieve the effect of avoiding graphic distortion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

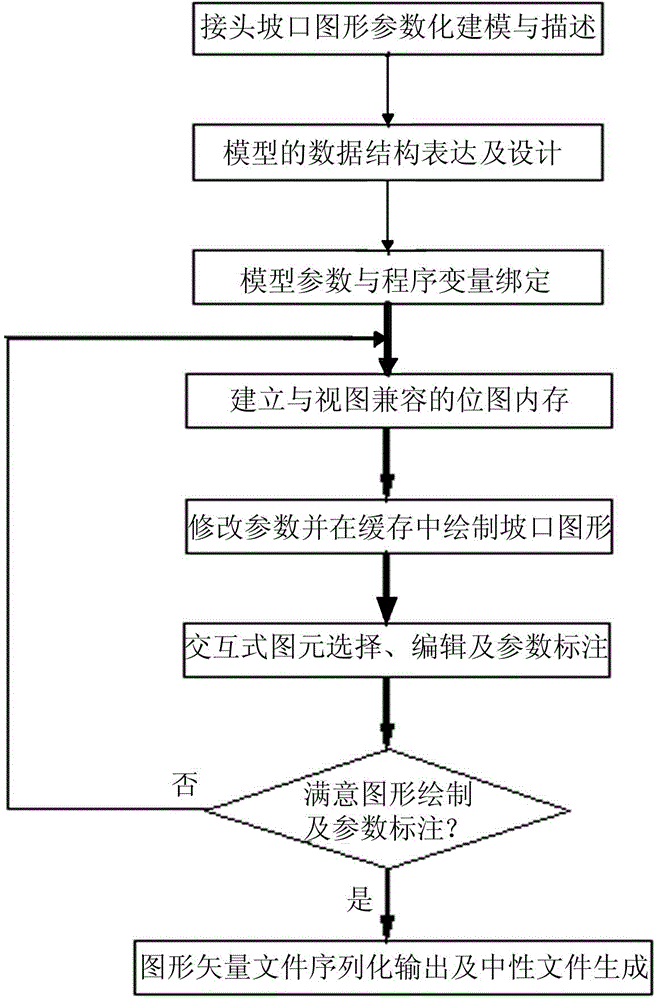

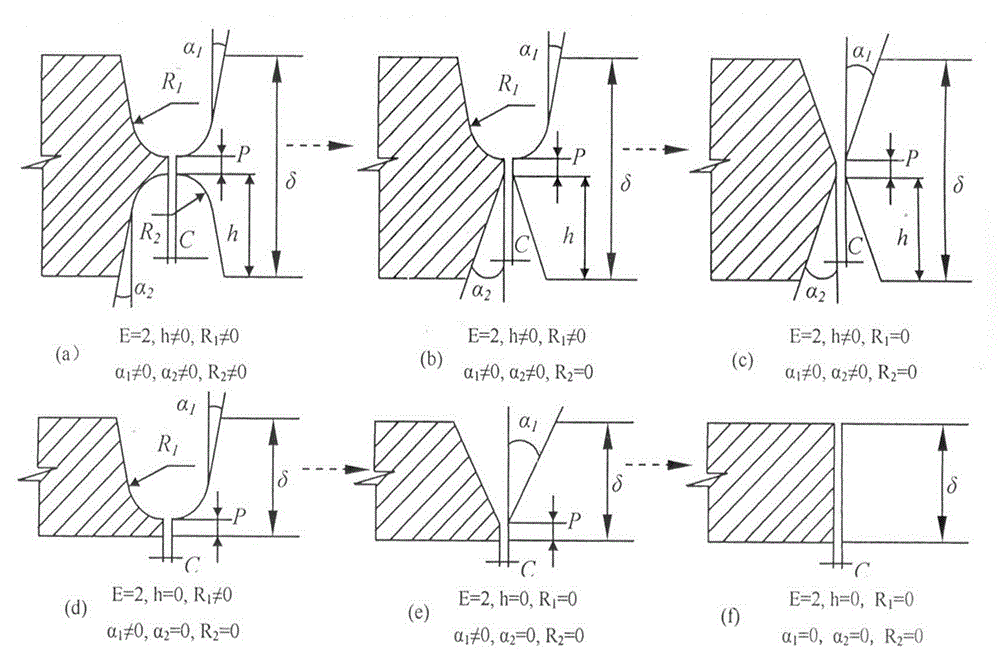

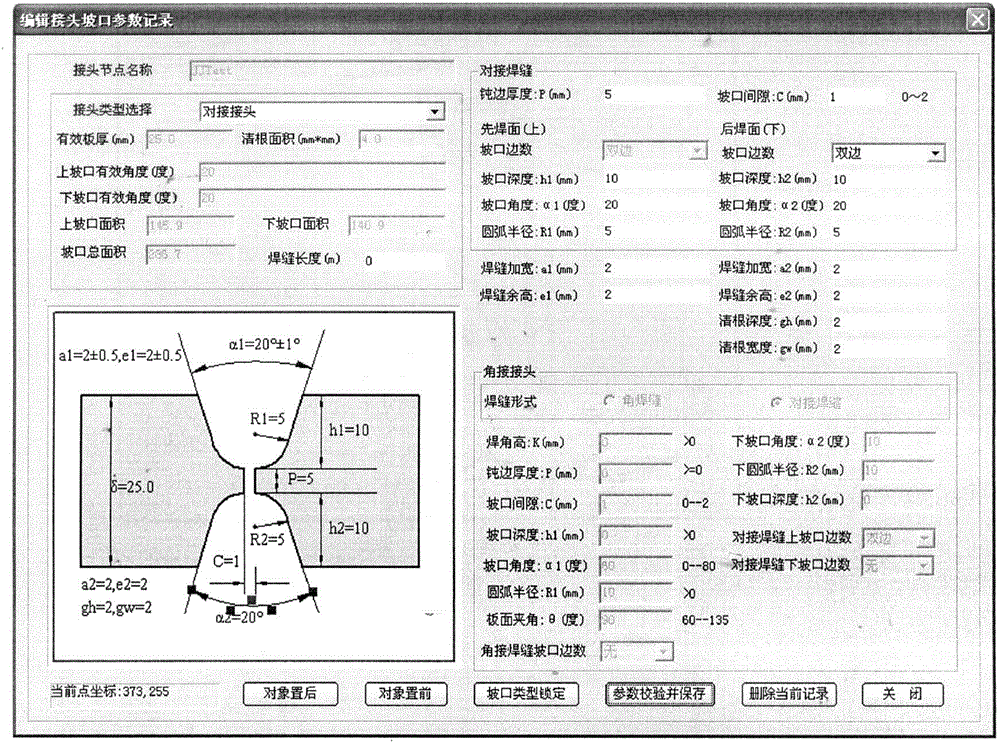

[0028] exist figure 1 Among them, the present invention provides an interactive welding joint groove pattern drawing and parameter labeling method, which includes the following steps: Step 1, first parametrically modeling the groove pattern, its main steps: 1a: analyzing commonly used grooves The shape characteristics of the type, on the basis of keeping the topological structure of the groove graph unchanged, classify the common types of welded joints; 1b: Parametric description and model representation of the joint groove graph, using the idea of variant design to realize the groove graph It evolves into different groove graphics with parameter changes, reflecting the shape evolution of groove graphics with parameter changes; 1c: Establish the binding of groove model parameters and program variables, and dynamically modify the groove model parameters through the value and change of variables to achieve The geometric shape and size of the graphics can be changed to realize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com