Gate line structure making local contact with obverse surface of solar battery and manufacturing method thereof

A solar cell and partial contact technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of restricting the conversion efficiency of solar cells, using a large amount of silver paste, and restricting the manufacturing cost of solar cells.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

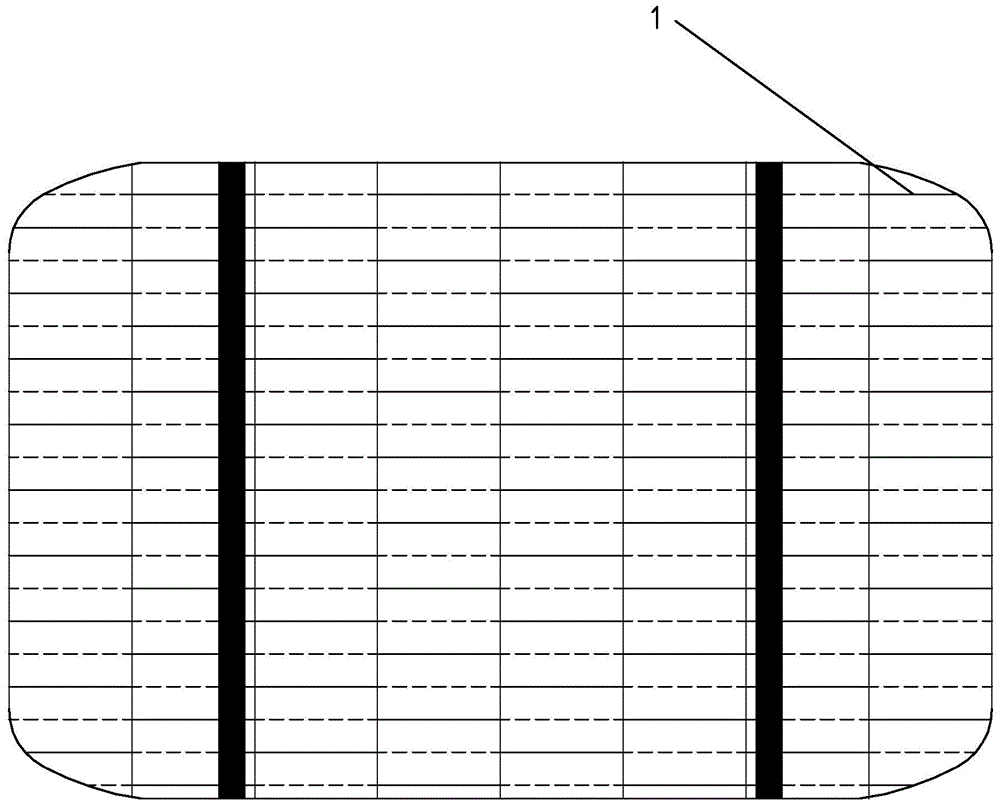

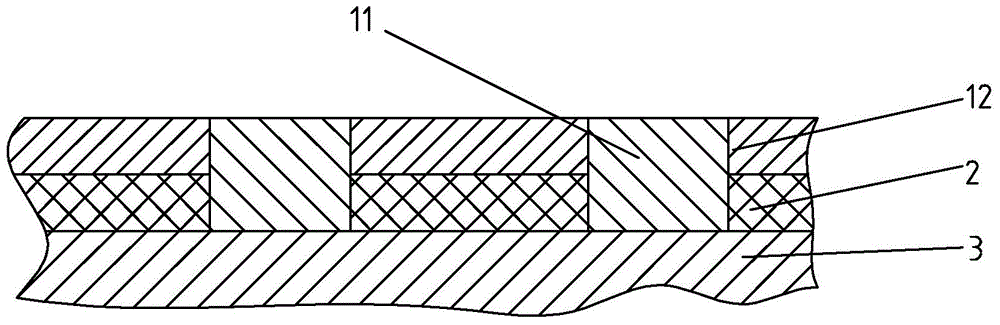

[0027] Such as figure 1 , 2 As shown, a grid line structure with partial contact on the front surface of a solar cell has a plurality of grid line electrodes 1, and each grid line electrode 1 has a plurality of sections of partial contact metal electrodes 11 and a plurality of sections of non-contact metal electrodes 12, and the partial contact metal electrodes 11 is electrically connected to the non-contact metal electrode 12, the non-contact metal electrode 12 is made of non-burn-through metal electrode paste, and the local contact metal electrode 11 passes through the dielectric film 2 of the battery to form an ohmic contact with the silicon substrate 3.

[0028] figure 1 In , the dotted line part in the gate line electrode 1 is the part not in contact with the silicon substrate 3 , and the realized part is the contact part with the silicon substrate 3 .

[0029] The local contact metal electrode 11 is made of a fire-through metal electrode paste, and the local contact me...

Embodiment 2

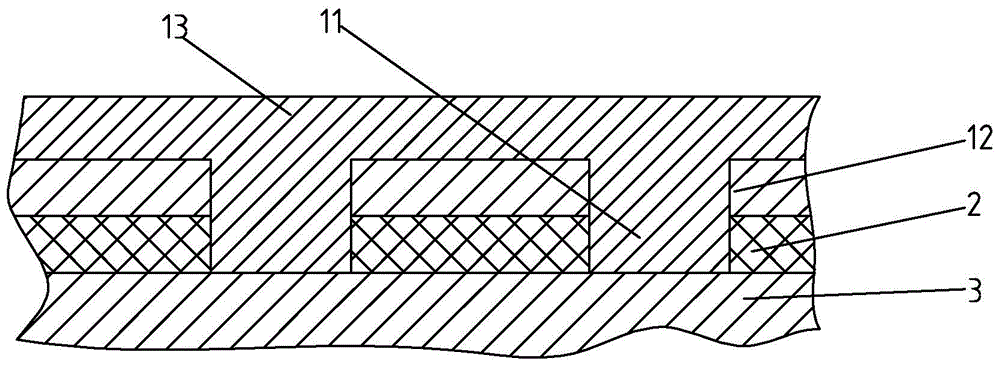

[0039] Such as figure 1 , 3 As shown, the grid line structure of this embodiment is basically the same as that of Embodiment 1, the difference is that each grid line electrode 1 is provided with a transmission electrode 13 made of a burn-through metal electrode paste, and the multi-section partial contact metal electrode 11 It is integrally made with the transfer electrode 13, and the transfer electrode 13 is also covered on the multi-segment non-contact metal electrode 12, and the finished solar cell has the same appearance as a conventional solar cell.

Embodiment 3

[0041] Such as figure 1 , 4 As shown, a grid line structure with partial contact on the front surface of a solar cell has a plurality of grid line electrodes 1, and each grid line electrode 1 has a plurality of sections of partial contact metal electrodes 11 and a plurality of sections of non-contact metal electrodes 12, and the partial contact metal electrodes 11 is electrically connected to the non-contact metal electrode 12, the non-contact metal electrode 12 is made of non-burn-through metal electrode paste, and the local contact metal electrode 11 passes through the dielectric film 2 of the battery to form an ohmic contact with the silicon substrate 3.

[0042] Such as image 3 As shown, the local contact metal electrode 11 is also made of non-burn-through metal electrode paste, the local contact metal electrode 11 and the non-contact metal electrode 12 are integrally made, and the local contact metal electrode 11 passes through the dielectric film 2 of the battery Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com