Active substance

A technology of active materials and active materials, applied in niobium compounds, climate sustainability, non-aqueous electrolyte batteries, etc., can solve problems such as difficulty in reducing electrode potential energy density, and achieve excellent high current performance, cycle performance, and high capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

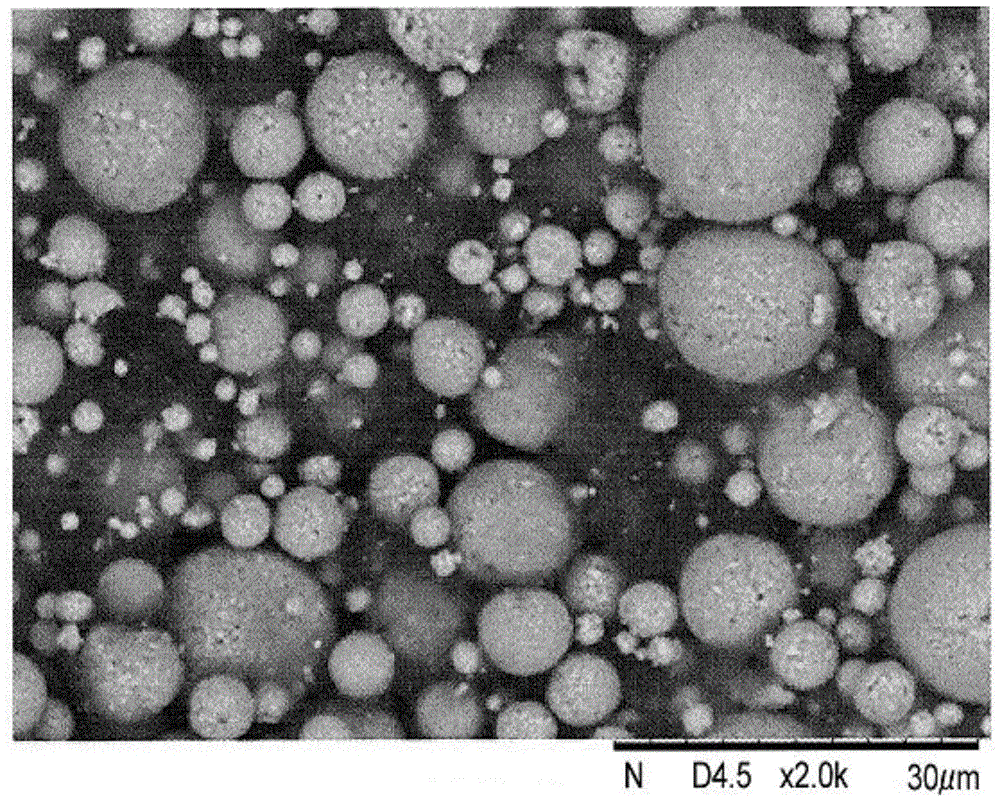

[0023] According to a first embodiment, an active substance is provided. The active material includes secondary particles and a carbon material phase formed on at least a portion of a surface of each of the secondary particles. Each of the secondary particles is composed of agglomerated active material primary particles. The primary particles of active materials include Li x m (1‐y) Nb y Nb 2 o (7+δ) A niobium composite oxide, wherein M is at least one selected from Ti and Zr, and x, y, and δ satisfy 0≤x≤6, 0≤y≤1, and -1≤δ≤1, respectively. The compression burst strength of the secondary particles is 10 MPa or higher.

[0024] Formula Li x m (1‐y) Nb y Nb 2 o (7+δ) The indicated niobium composite oxide can provide a battery capable of stably repeating rapid charge and discharge without impairing rate performance and energy density for the reasons described below.

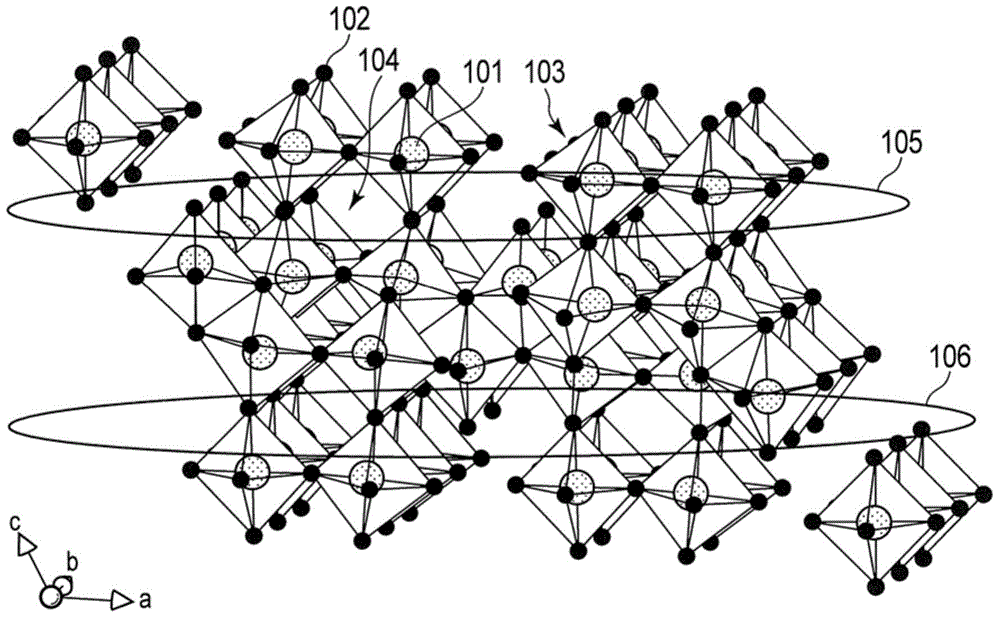

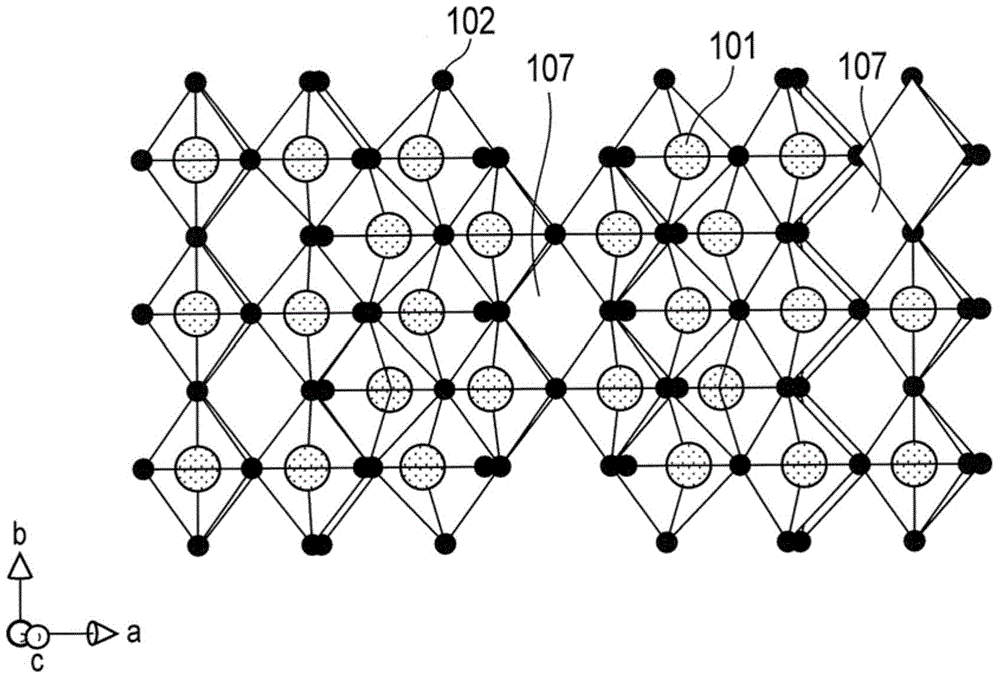

[0025] The following will refer to figure 1 and 2 An example of a crystal structure of a niobium com...

no. 2 approach

[0100] According to a second embodiment, a method of producing an active substance is provided. Active species include Li x m (1‐y) Nb y Nb 2 o (7+δ) A niobium composite oxide, wherein M is at least one selected from Ti and Zr, and x, y, and δ satisfy 0≤x≤6, 0≤y≤1, and -1≤δ≤1, respectively. The method includes: providing a niobium composite oxide according to a solid phase reaction; grinding the niobium composite oxide to provide a ground product; forming the ground product into secondary particles; sintering the secondary particles; a surface of a sintered secondary particle, formed including the secondary particle and the carbon precursor; and the carbonized carbon precursor.

[0101] Hereinafter, a method of producing an active substance according to the second embodiment is explained.

[0102] First, for example, as described below, a niobium composite oxide is obtained by a solid phase reaction. However, the method of obtaining the niobium composite oxide is not li...

no. 3 approach

[0116] According to a third embodiment, there is provided a nonaqueous electrolyte battery. The nonaqueous electrolyte battery includes a positive electrode, a negative electrode, and a nonaqueous electrolyte. The negative electrode includes the active material according to the first embodiment.

[0117] The nonaqueous electrolyte battery according to the third embodiment may further include a separator provided between the positive electrode and the negative electrode, a container containing the positive electrode, the negative electrode, the separator, and the nonaqueous electrolyte, a positive terminal, and a negative terminal. The positive electrode can be spatially separated from the negative electrode in such a manner that a separator is sandwiched between the electrodes. The negative terminal can be electrically connected to the negative electrode. The positive terminal can be electrically connected to the positive electrode.

[0118] Hereinafter, the container, nega...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com