Grid structure of lead-acid storage battery

A lead-acid battery, grid technology, applied in the direction of electrode carrier/current collector, etc., can solve problems such as the adverse effect of battery consistency, deformation of lead-acid battery grid, softening and falling off of active materials, etc., to avoid premature failure and improve the structure. Strength, the effect of increasing specific energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

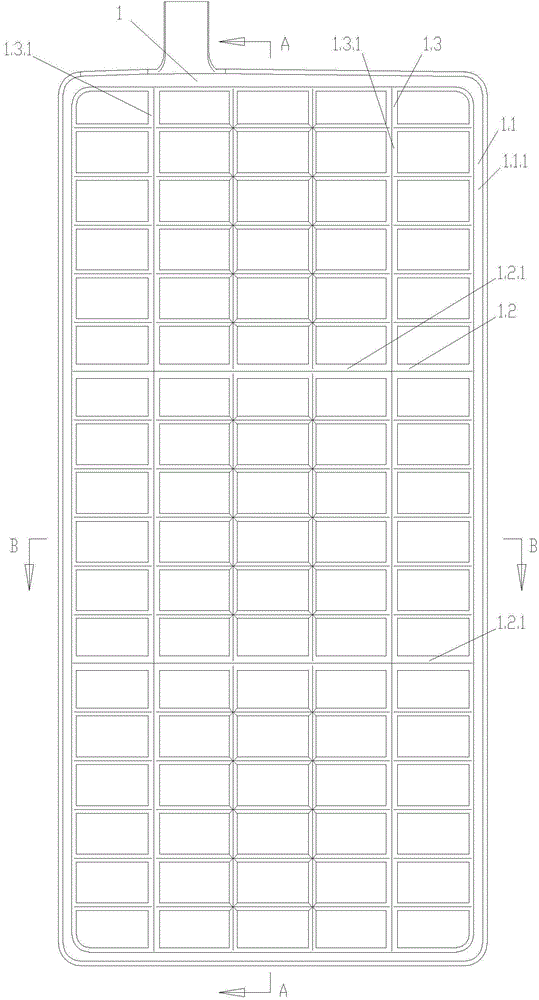

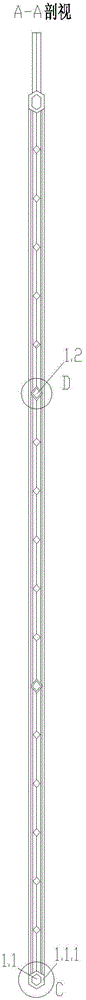

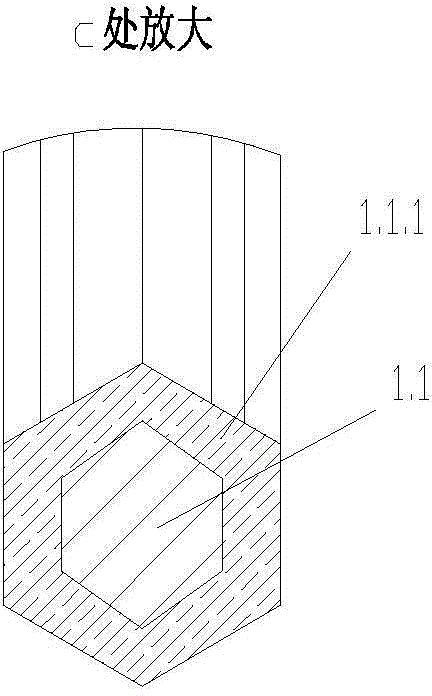

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 As shown, the present invention includes a lead core net 1, and the lead core net 1 includes a frame 1.1, several vertical ribs, some horizontal ribs, several horizontal ribs 1.2, and several vertical ribs 1.3; frame 1.1 and horizontal and vertical reinforcement The outer surfaces of the ribs 1.2, 1.3 are provided with outer coatings 1.1.1, 1.2.1, 1.3.1. Preferably, the lead core mesh 1 is made of pure lead, lead-tin alloy, lead-calcium-tin-aluminum alloy or low-antimony lead alloy, and this embodiment is made of pure lead.

[0021] In this embodiment, the frame 1.1 is a rectangle with smooth transitions at four corners, and the left side of the upper side of the frame 1.1 is provided with tabs. The cross-sectional shapes of the other three sides of the frame are all regular hexagons, and the side lengths of the left and right sides of the cross-section of the upper side of ...

Embodiment 2

[0025] The difference between embodiment two and embodiment one is that the thickness of the outer covering layer 1.1.1, 1.2.1, 1.3.1 is greater than or equal to 0.5 mm, less than or equal to 2 mm, preferably 0.8 mm; the outer covering layer 1.1.1 , 1.2.1, 1.3.1 are plastic layers or conductive plastic layers, and the outer coating layers 1.1.1, 1.2.1, 1.3.1 of this embodiment are PP plastic layers, which are coated on the frame, transverse ribs, On the outer surface of the vertical rib, the surface of the outer cladding should be trimmed after the injection molding is completed.

Embodiment 3

[0027] The difference between the third embodiment and the second embodiment is that the outer cladding layers 1.1.1, 1.2.1, and 1.3.1 are aluminum oxide ceramic layers, and the outer cladding layers 1.1.1, 1.2.1, and 1.3.1 are made of The method of pressing is coated on the outer surfaces of the frame, the horizontal ribs and the vertical ribs.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com