Flame-proof type disc copper alloy flat belt pulley motor

A flat pulley, copper alloy technology, applied in the field of flameproof disc copper alloy flat pulley motor, can solve the problems of increased heat generation, increased linear speed of motor bearings, increased internal friction, etc. Radial force and super rigid structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below with reference to the drawings and specific embodiments;

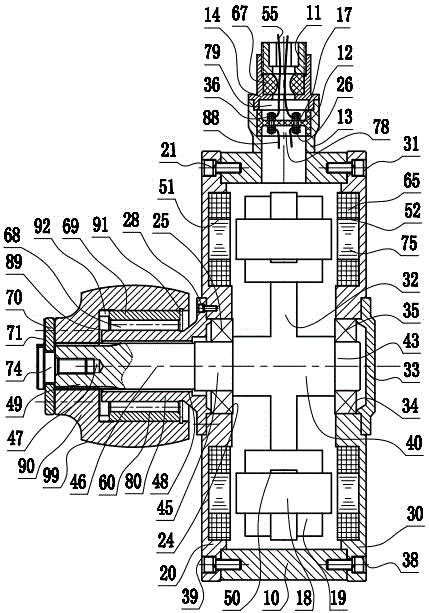

[0033] An explosion-proof disk-type copper alloy flat pulley motor, including a motor housing 10, a front end cover 20, a rear end cover 30, a rotor bracket 32, a motor shaft 40, a front bearing 25, a rear bearing 35, a permanent magnet 18, and a front stator 51 And the rear stator 52 and the flat pulley 90, as an improvement: the inner lead 88 of the motor housing 10 is fixedly connected to the junction box seat 13 at the outlet, the outer end of the junction box seat 13 has a cable box end cover 14, and the lead hole seat 11 is located in the wire box On the end cover 14, the external lead 55 passes through the lead hole seat 11; the front stator 51 and the rear stator 52 are composed of a stator core 75 and an armature winding 65. The motor rotor 50 is composed of six rotor cores 19 and installed on adjacent rotor cores. 19 is composed of permanent magnets ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com