LED constant current driver

A technology of constant current driver and converter, which is applied in the direction of conversion equipment, lighting devices, light sources, etc. without intermediate conversion to AC, to achieve the effect of eliminating loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

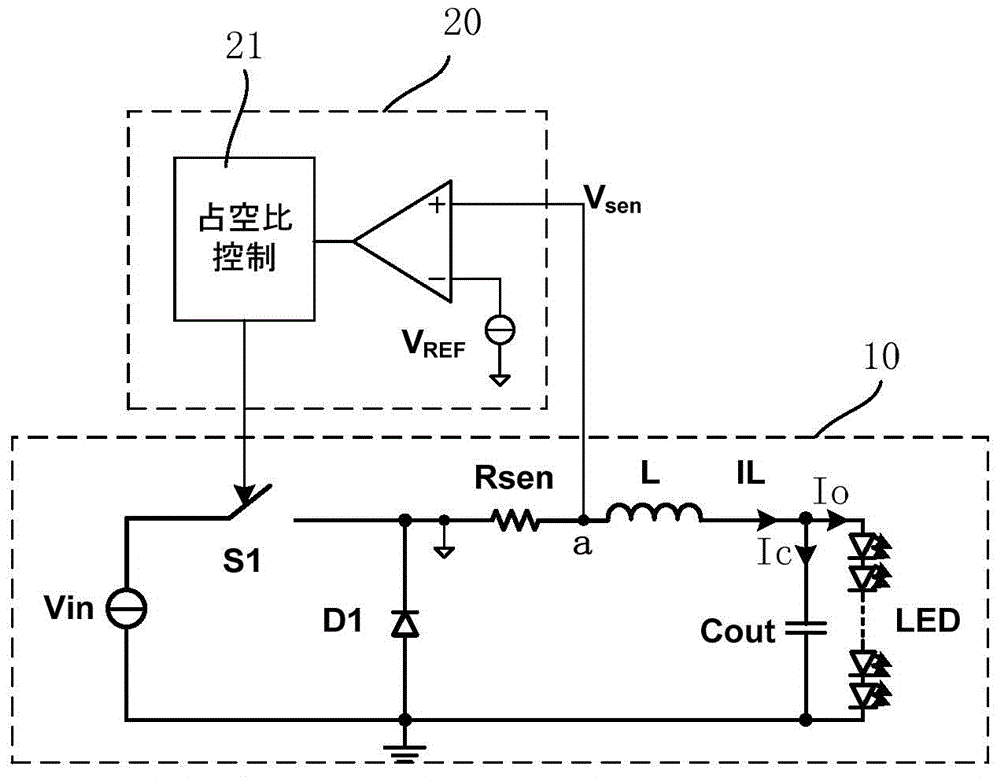

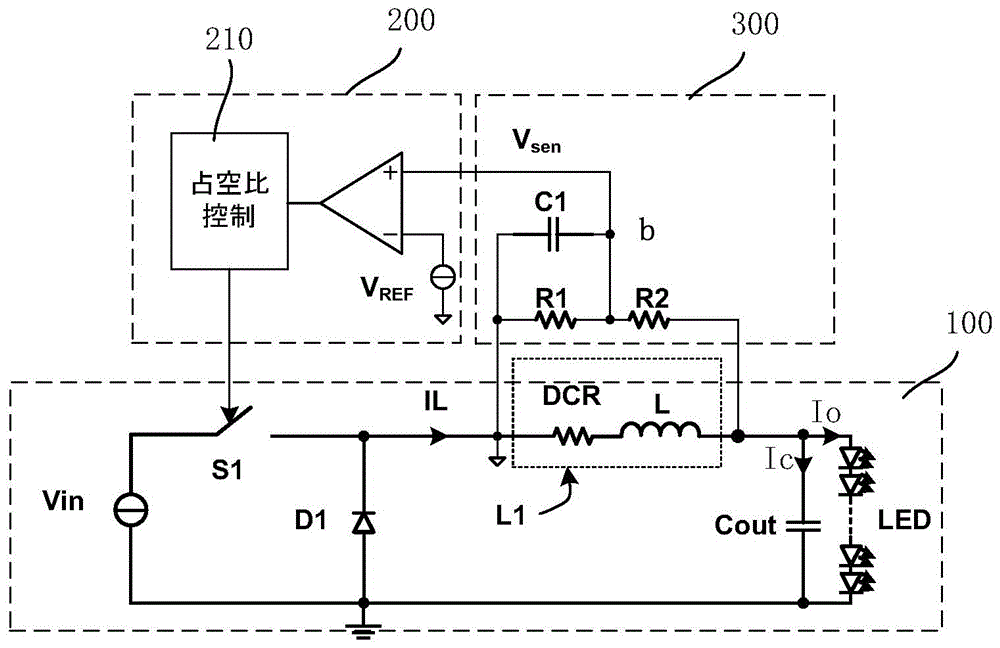

[0026] In order to save cost and improve the conversion efficiency of the system, the present invention proposes a method for realizing constant current control by sampling the inductance series impedance.

[0027] In order to make the purpose, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] figure 2 Shown is the circuit structure of the constant current driver provided in this embodiment. Specifically, it includes a step-down converter unit 100 , a control circuit unit 200 and a sampling unit 300 . The sampling unit 300 is connected in parallel with the inductor L in the step-down converter unit 100 to sample the inductor current I passing through the inductor L L , and provide a feedback signal to the control circuit unit 200, the control circuit unit 200 according to the feedback signal and the reference voltage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com