Solar cell panel automatic cleaning device and transfer connection machine thereof

A solar panel and automatic cleaning technology, applied in solar thermal power generation, solar thermal energy, solar collectors, etc., can solve problems such as solar power generation constraints, component attenuation, and component hot spot effects, and achieve remote monitoring and control of the cleaning process. Control, High Reliability Cleaning, Effect of Cleaning Process Automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

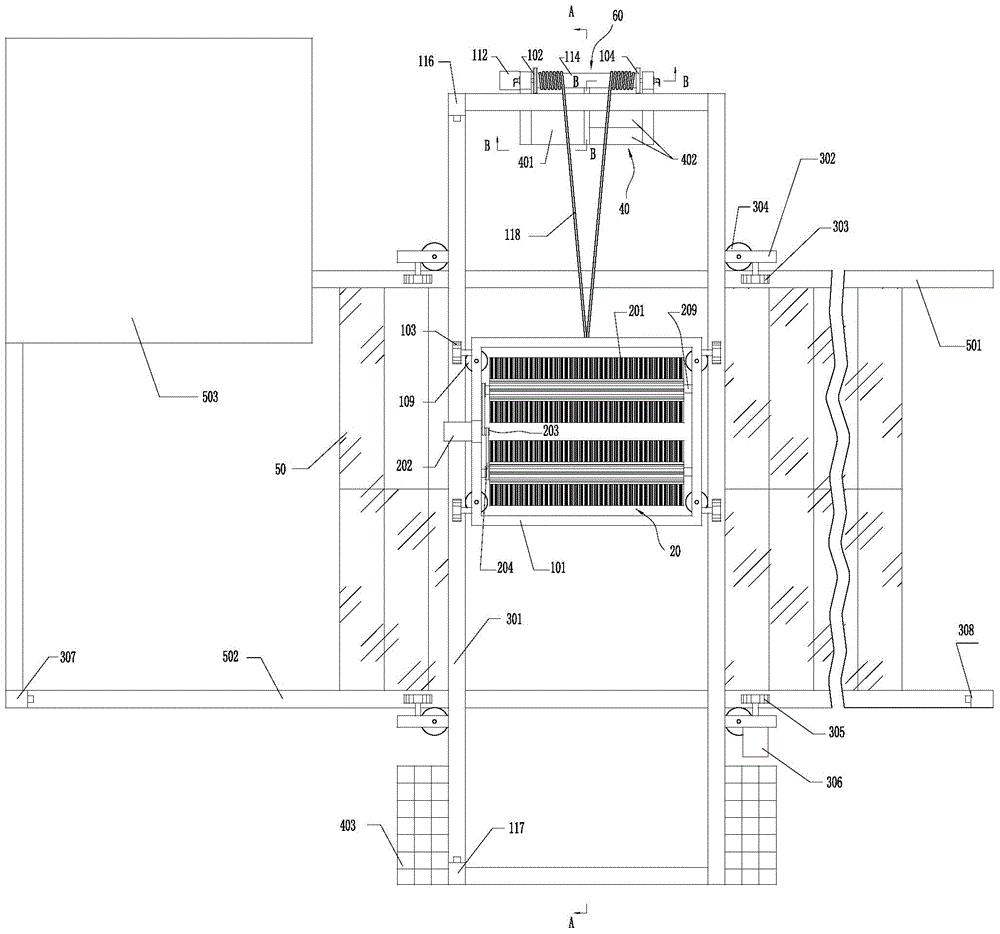

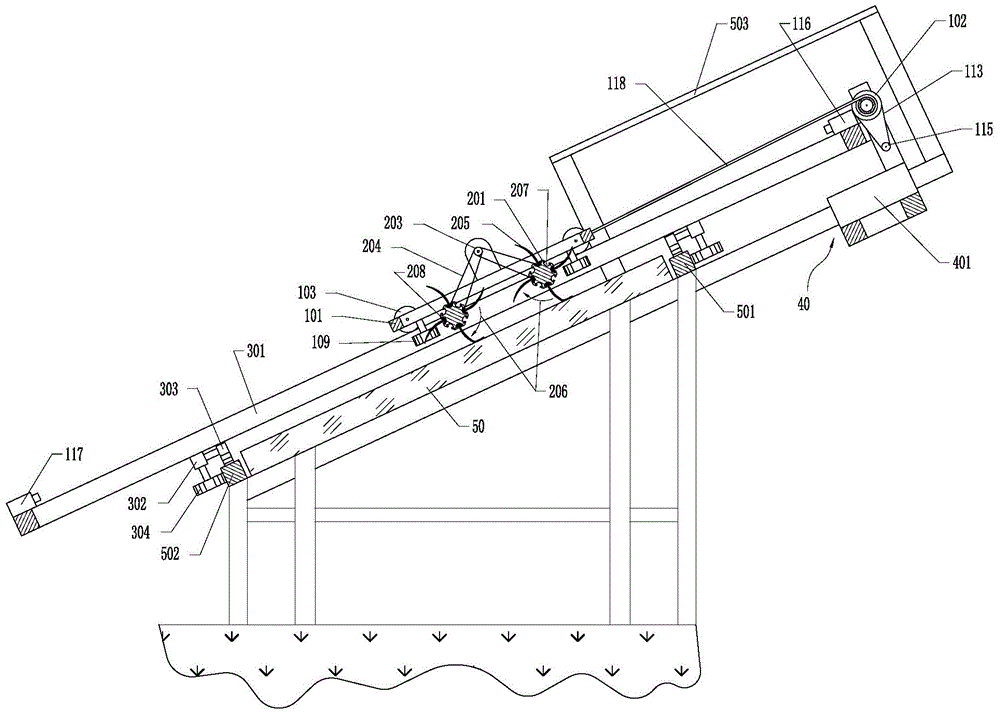

[0029] The solar panel automatic cleaning device of the present invention is applied to a large-scale solar power station. As everyone knows, a solar power station is composed of several rows of solar panel groups 50 arranged at intervals before and after, and each row of solar panel groups 50 is composed of several solar panel groups. The solar cell panels are constructed in the manner of adjoining up and down and connecting side by side. Each row of solar panel arrays 50 can be several kilometers in length. The width of the solar cell panel group 50 ranges from one meter to several meters, and the solar cell panels in the solar cell panel group 50 are installed and fixed toward the sun, forming an inclination angle with the ground. The solar cell panel group 50 has an upper edge and a lower edge, and the upper edge is higher than the lower edge.

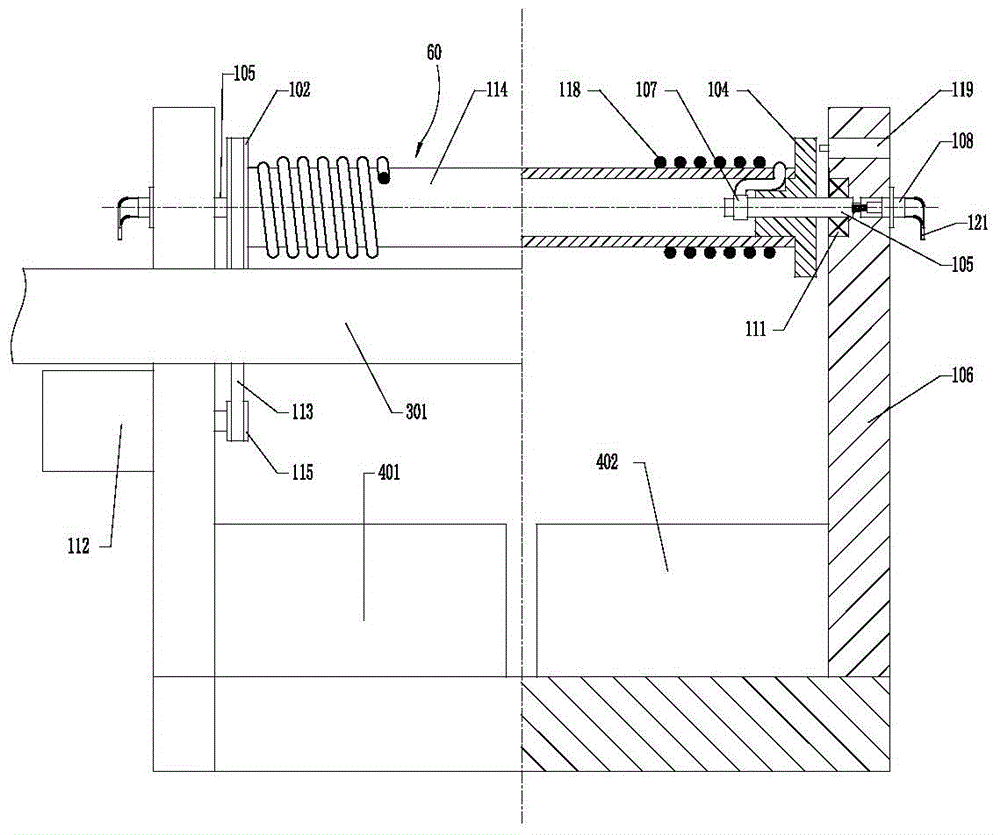

[0030] Such as Figure 1-3 As shown, a pair of guide rails 501 and 502 are arranged in parallel on the upper and lower edges of...

Embodiment 2

[0070] Such as Figure 4 As shown, the difference between this embodiment and embodiment 1 is:

[0071] The cleaning frame 101 described in Embodiment 1 is not provided on the moving frame 301 , but a closed conveyor belt 604 with a plurality of microfiber flexible cleaning sheets 205 arranged on the outer surface.

[0072] The upper end of the mobile frame 301 is provided with a tension column 602, and the lower end is provided with an electric drive column 601, and the conveyor belt 604 is looped between the tension column 602 and the drive column 601 and driven by the electric drive column 601 circular movement. The tension posts 602 provide the necessary tension to the conveyor belt 604 for it to move. The direction of motion of the conveyor belt 604 is counterclockwise (with Figure 4 The surface of the paper is the reference direction), thus, the flexible cleaning sheet 205 on it is moved from top to bottom along the surface of the solar panel in the solar panel group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com