In-furnace retro-reflectors with steerable tunable diode laser absorption spectrometer

A retro-reflection, optical device technology, applied in the field of internal combustion characteristics, which can solve the problems of limited practicability of traditional systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Unless otherwise indicated, all numbers expressing numbers of elements, dimensions, reaction conditions, etc. used in the specification and claims are understood to be modified in all instances by the term "about".

[0044] In this application and claims, the use of the singular includes the plural unless specifically stated otherwise. Also, the use of "or" means "and / or" unless stated otherwise. Furthermore, use of the term "including" as well as other forms such as "includes" and "included" is not limiting. Likewise, terms such as "element" or "component" encompass both elements and components comprising one unit and elements and components comprising more than one unit, unless specifically stated otherwise.

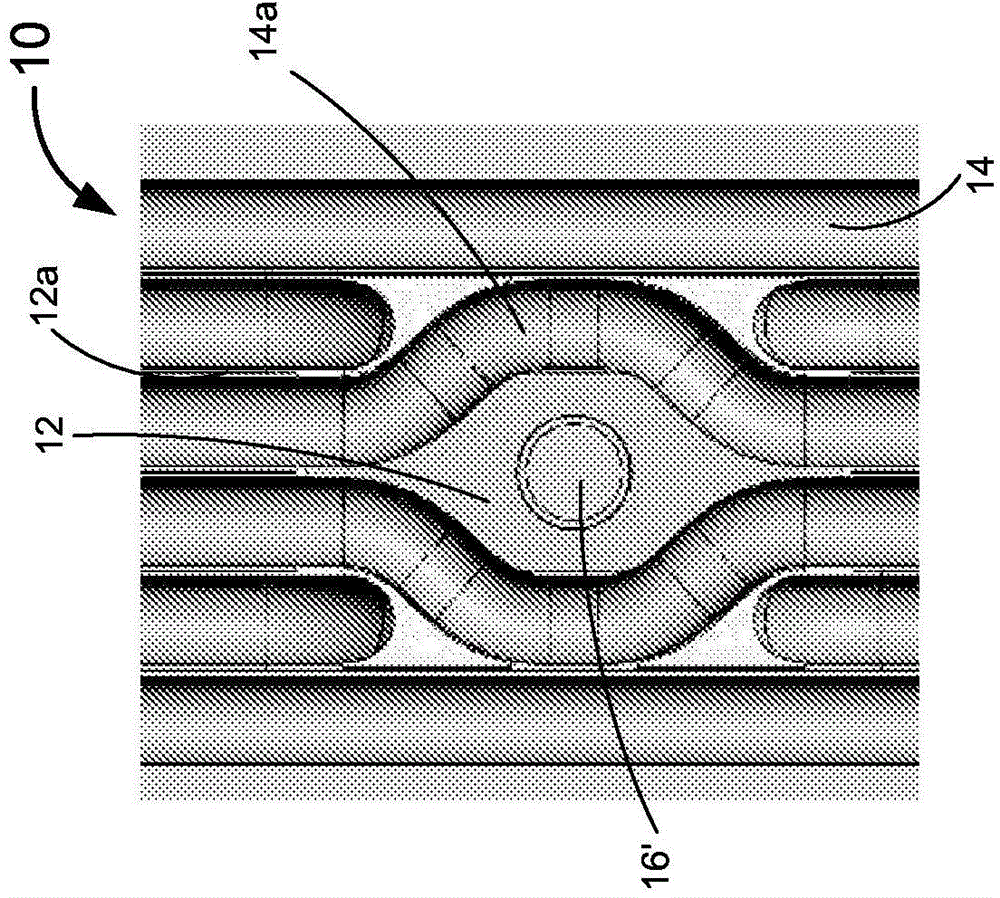

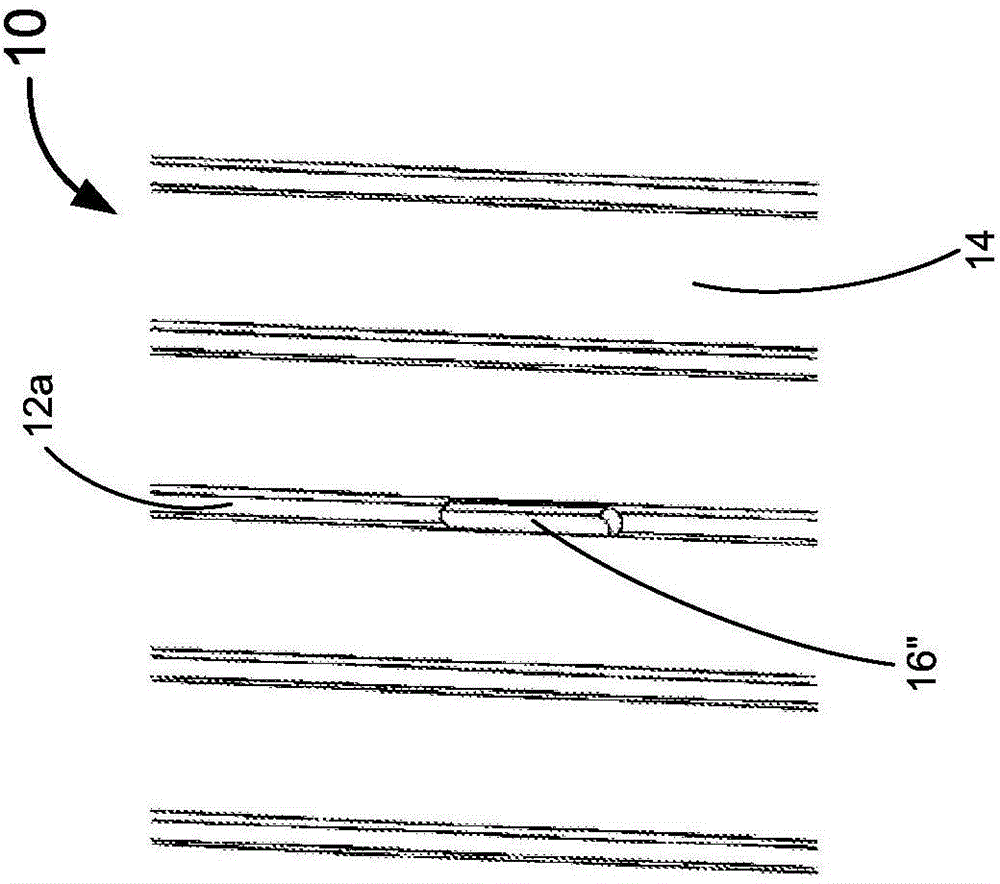

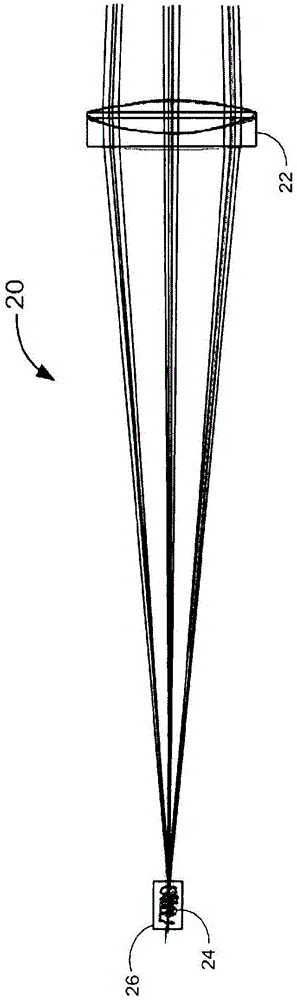

[0045] US Patent No. 7,469,092, the entire contents of which is hereby incorporated herein, discloses a method and apparatus for monitoring and controlling a combustion process of the type that requires installation of tube bends in the walls of the boiler in o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com