Slurry for lithium ion secondary battery negative electrodes, electrode for lithium ion secondary batteries, method for producing electrode for lithium ion secondary batteries, and lithium ion secondary battery

A secondary battery, lithium ion technology, applied in battery electrodes, secondary batteries, non-aqueous electrolyte battery electrodes, etc., can solve the problem of reduced cycle characteristics, and achieve the effect of excellent adhesion and excellent cycle characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

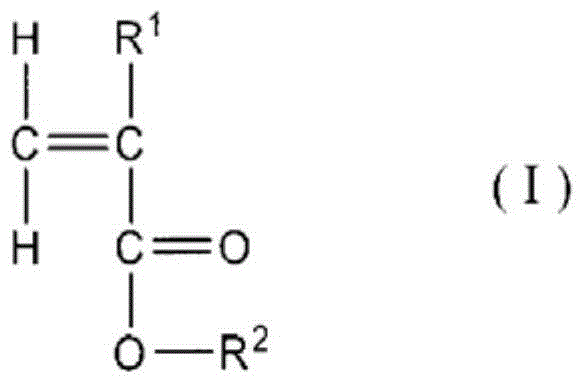

Method used

Image

Examples

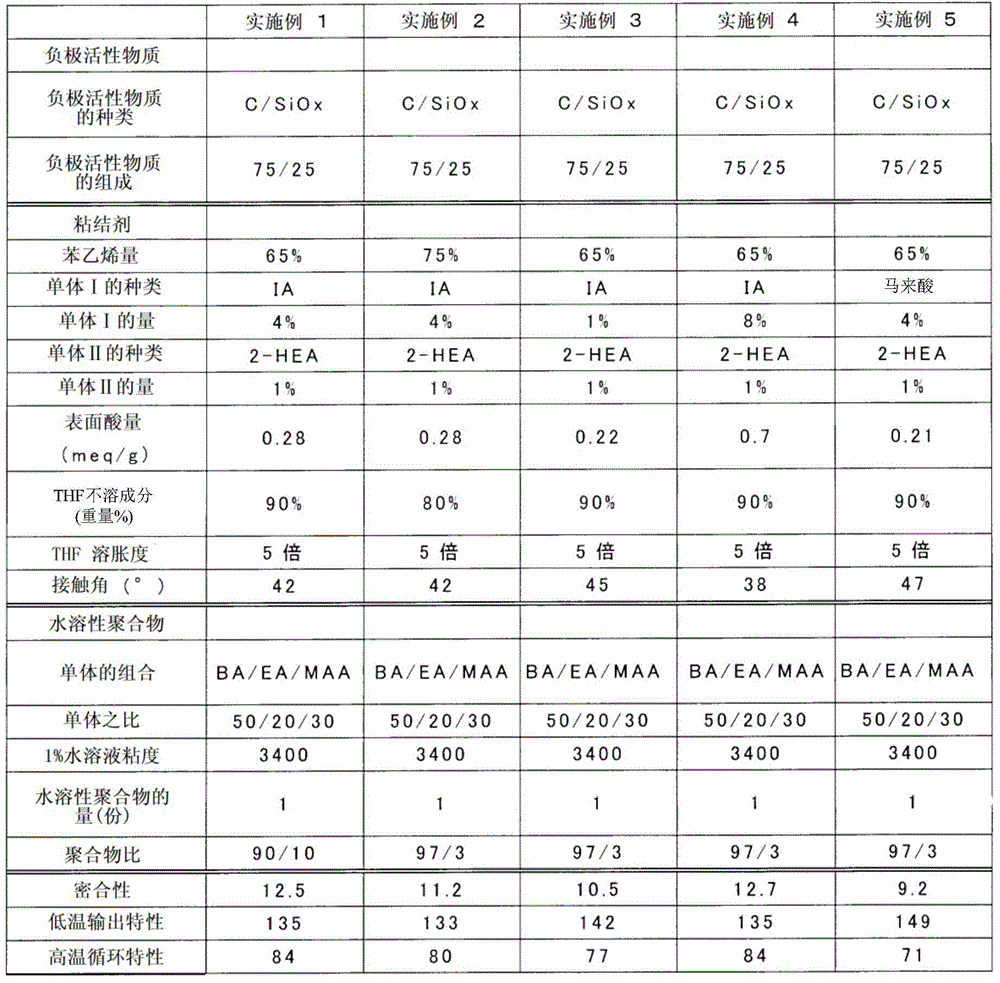

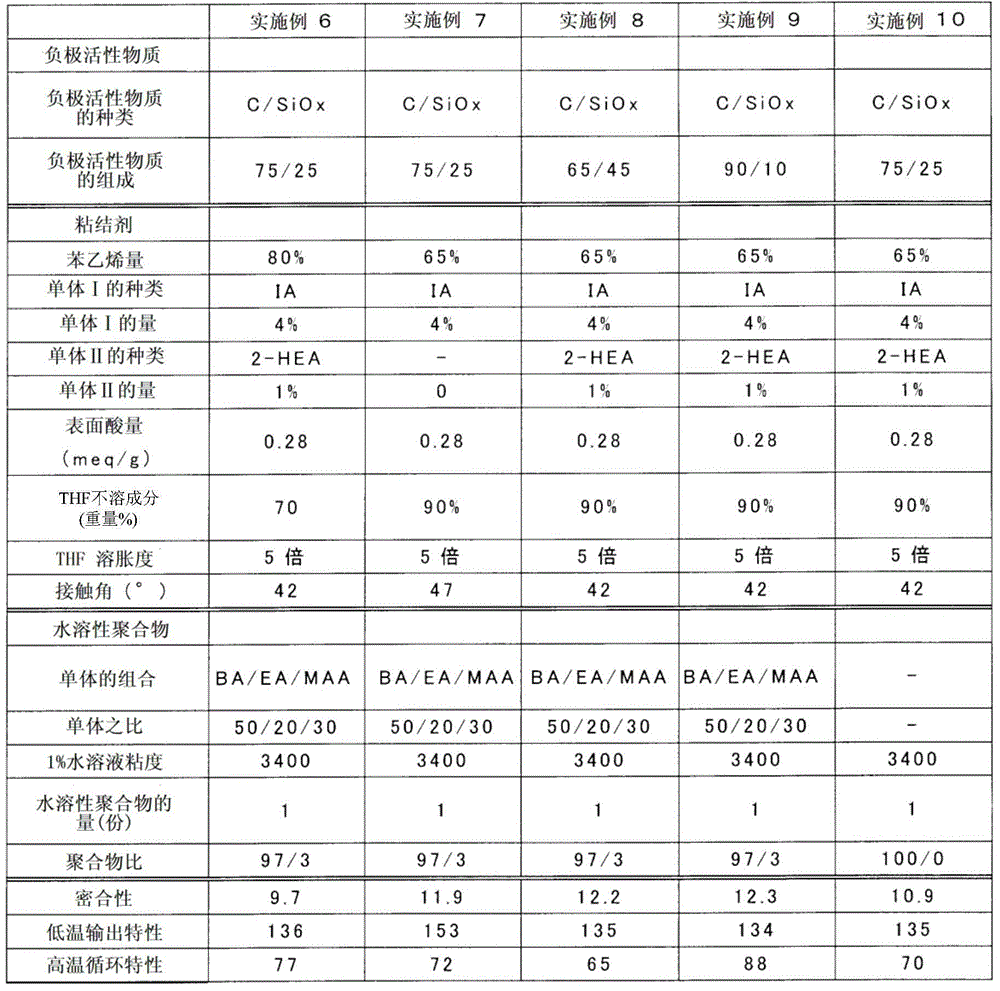

Embodiment 1

[0268] (1-1. Production of Particulate Polymer)

[0269] Add 30 parts of 1,3-butadiene, 4 parts of itaconic acid as an ethylenically unsaturated carboxylic acid monomer, and 65 parts of styrene as an aromatic vinyl monomer in a 5MPa pressure-resistant container with a stirrer, as 1 part of 2-hydroxyethyl acrylate containing a hydroxyl monomer, 4 parts of sodium dodecylbenzenesulfonate as an emulsifier, 150 parts of ion-exchanged water, and 0.5 parts of potassium persulfate as a polymerization initiator, after fully stirring , heated to 50 ° C to initiate polymerization.

[0270] When the polymerization conversion ratio reached 96%, cooling was performed to terminate the reaction, and a mixture containing a particulate polymer (SBR) as a binder was obtained. A 5% sodium hydroxide aqueous solution was added to the above-mentioned mixture containing the particulate polymer to adjust pH to 8. Thereafter, unreacted monomers were removed by heating and vacuum distillation. Then, ...

Embodiment 2

[0290] In the above (manufacture of 1-1. particulate-form polymer), the quantity of 1, 3- butadiene was changed into 20 parts, and the quantity of styrene was changed into 75 parts.

[0291] In the above (1-3. Manufacture of negative electrode slurry), the amount of the 1% aqueous solution of carboxymethylcellulose was changed to 0.97 parts in terms of solid content, and the amount of the aqueous solution containing the water-soluble polymer 1 It was changed to 0.03 parts based on the amount of the water-soluble polymer 1.

[0292] Except for the above matter, it carried out similarly to Example 1, the slurry for negative electrodes, a negative electrode, and a lithium ion secondary battery were manufactured and evaluated.

Embodiment 3

[0294] In the above (manufacture of 1-1. particulate-form polymer), the quantity of 1, 3- butadiene was changed to 33 parts, and the quantity of itaconic acid was changed to 1 part.

[0295] In the above (1-3. Manufacture of negative electrode slurry), the amount of the 1% aqueous solution of carboxymethylcellulose was changed to 0.97 parts in terms of solid content, and the amount of the aqueous solution containing the water-soluble polymer 1 It was changed to 0.03 parts based on the amount of the water-soluble polymer 1.

[0296] Except for the above matter, it carried out similarly to Example 1, the slurry for negative electrodes, a negative electrode, and a lithium ion secondary battery were manufactured and evaluated.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com