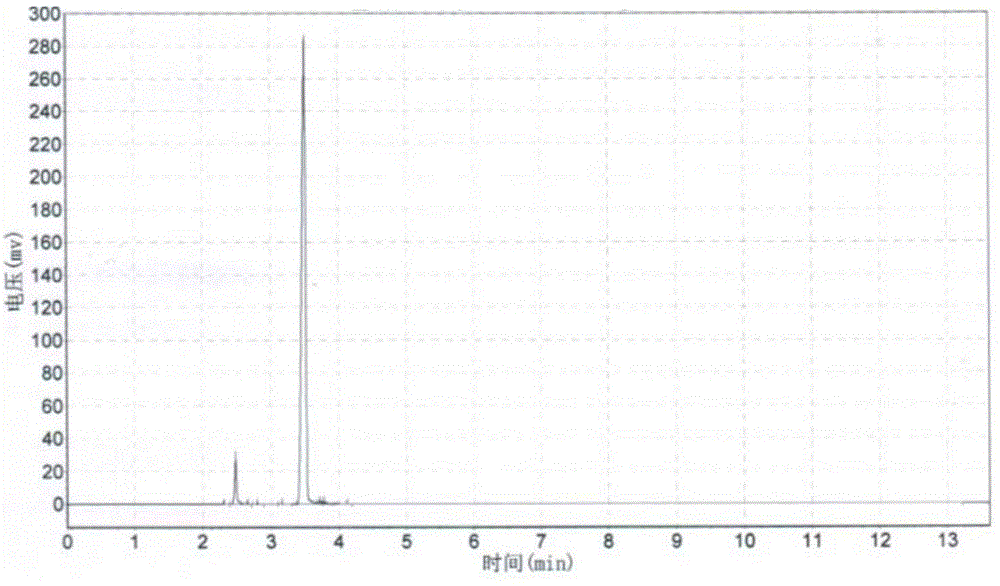

Apparatus and method used for purifying chloropentafluorobenzene

A technology of pentafluorochlorobenzene and crystallizer, which is applied in the field of devices for purifying pentafluorochlorobenzene, can solve the problems of difficulty in meeting product use requirements, unsatisfactory product purity, time-consuming and labor-intensive, etc. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

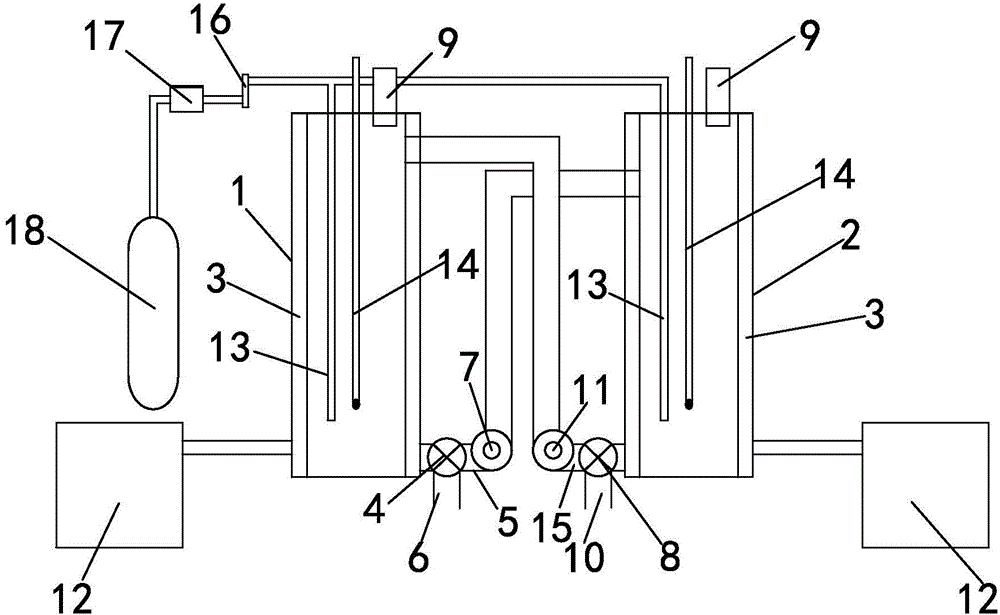

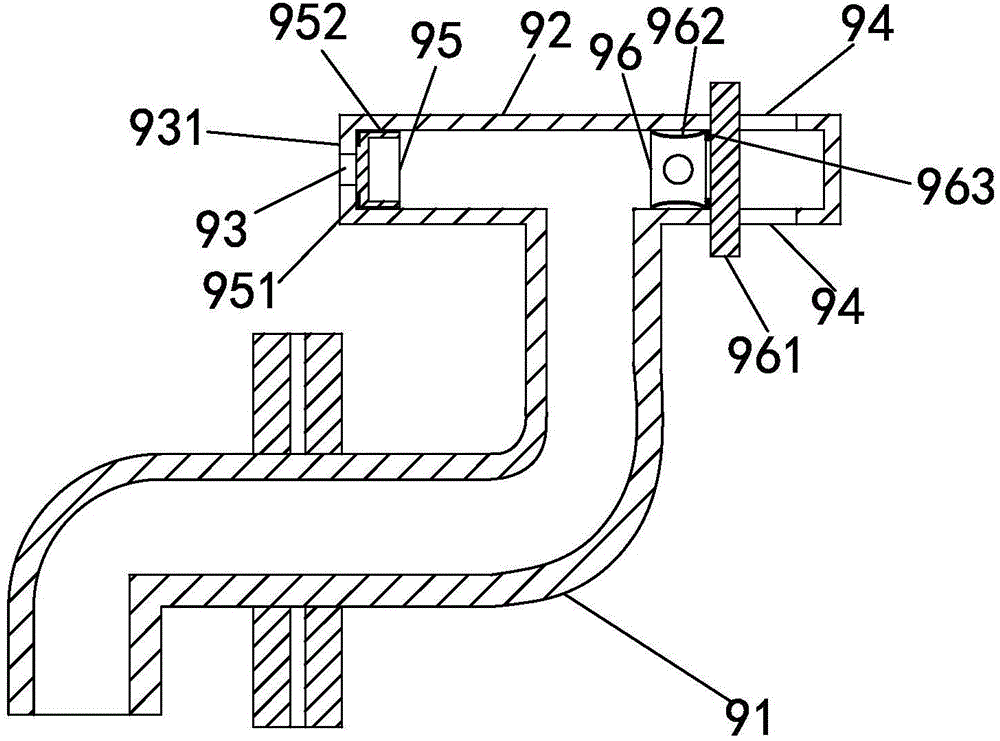

[0057] Such as Figure 1 to Figure 4 As shown, a device for purifying pentafluorochlorobenzene includes a crystallization system, and the crystallization system includes a crystallizer and a super constant temperature water bath 12. The raw material of pentafluorochlorobenzene is crystallized in a crystallizer and refined. The crystallizer includes a first crystallizer 1 and a second crystallizer 2, and the first crystallizer 1 and the second crystallizer 2 have the same specification and size. The outer sides of the first crystallizer 1 and the second crystallizer 2 are connected with a jacket 3, and the jacket 3 is connected with a super constant temperature water bath 12, so there are two super constant temperature water baths 12, which act on the first crystallizer 1 and the second crystallizer respectively. Device 2. The super constant temperature water bath 12 regulates the temperature of the first crystallizer 1 and the second crystallizer 2 through the jacket 3 to re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com