Acid exhaust gas absorption tank

An acid tail gas and absorption tank technology, which is applied in the directions of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of difficulty in ensuring the acid tail gas absorption rate and absorption effect, and the acid tail gas cannot be evenly distributed, etc. The effect of convenient maintenance and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

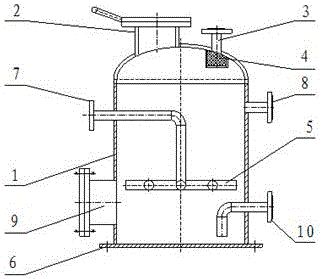

[0027] In order to reduce the emission of acid tail gas, especially to deal with a small amount of acid tail gas, and reduce the cost under the premise of meeting the environmental protection emission requirements, this embodiment provides figure 1 The acidic tail gas absorption tank shown is an acidic tail gas absorption tank, comprising an absorption tank body 1, and the top of the absorption tank body 1 is provided with a lye filling port 2 and a residual gas outlet 3; the side of the absorption tank body 1 The wall is provided with an exhaust gas inlet 7 and an alkali liquor outlet 10, and a gas distributor 5 is arranged inside the absorption tank body, and the gas distributor 5 communicates with the exhaust gas inlet 7 through a pipeline.

[0028] When in use, first inject lye from the lye filling port 2, then lead the acidic tail gas into the gas distributor 5 connected to the tail gas inlet 7 through the tail gas inlet 7, and the acidic tail gas passes through the gas di...

Embodiment 2

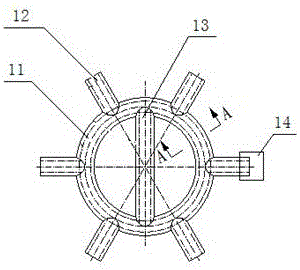

[0032] On the basis of Example 1, in order to reduce the emission of acid tail gas, this example provides figure 2 Shown gas distributor 5, described gas distributor 5 is made up of annular pipe 11, branch pipe 12 and connecting pipe 13; The end portion of the pipe is connected with a blocking plate 14; the connecting pipe 13 communicates with the inner side of the annular pipe 11;

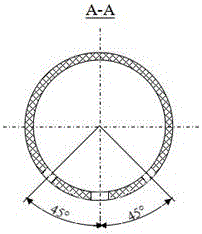

[0033] The sectional view of the annular pipe 11 of the gas distributor 5 is as image 3 shown.

[0034] When working, it should be ensured that the opening of the gas distributor 5 is downward, and the acidic tail gas entering the absorption tank body 1 can be evenly distributed through the porous structure of the gas distributor 5, so that the acidic tail gas can fully contact with the lye, ensuring the absorption rate and Effect.

[0035] Due to the use of the gas distributor 5 provided in this embodiment, the uniform distribution of the gas entering the absorption tank body 1 can be ensure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com