Steel coil height centering device and method thereof

A technology for centering devices and steel coils, which can be used in guiding/positioning/alignment devices, metal processing, metal processing equipment, etc. Roll centering is susceptible to interference and other issues, achieving the effect of not being easily interfered, easy to install and maintain the device, and ample operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

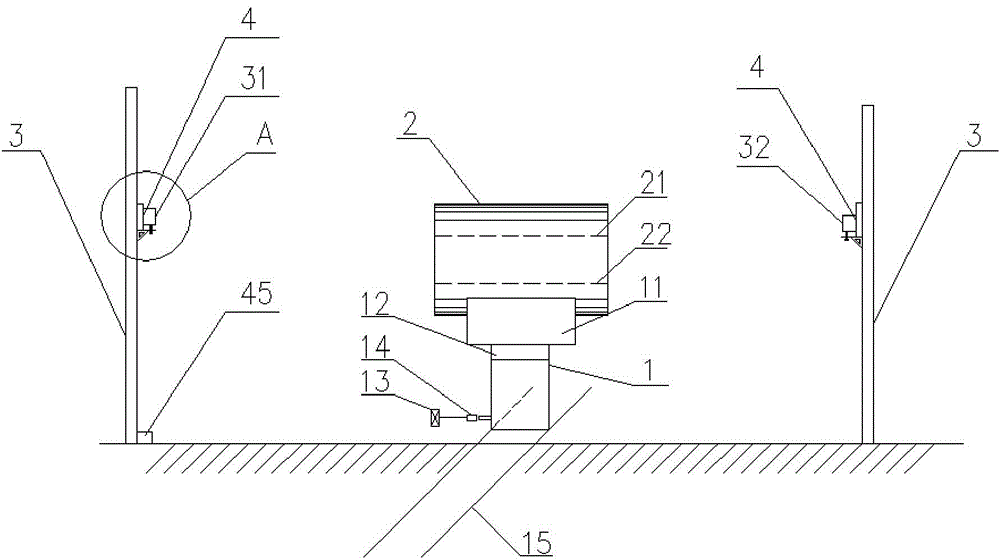

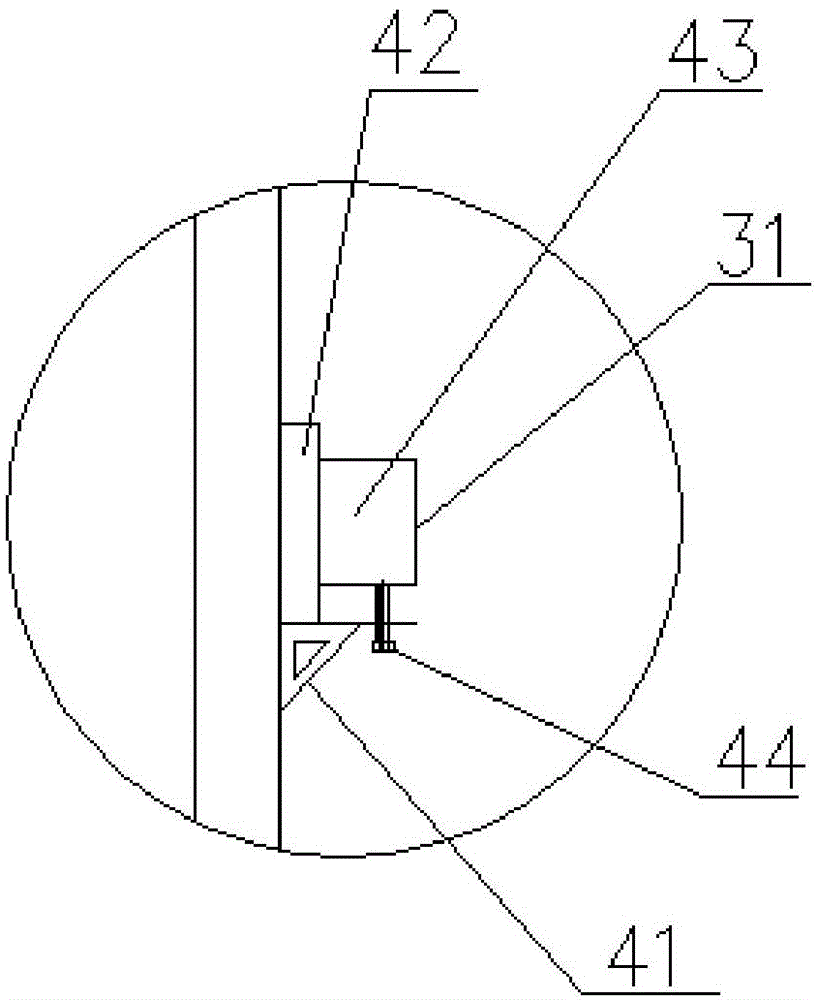

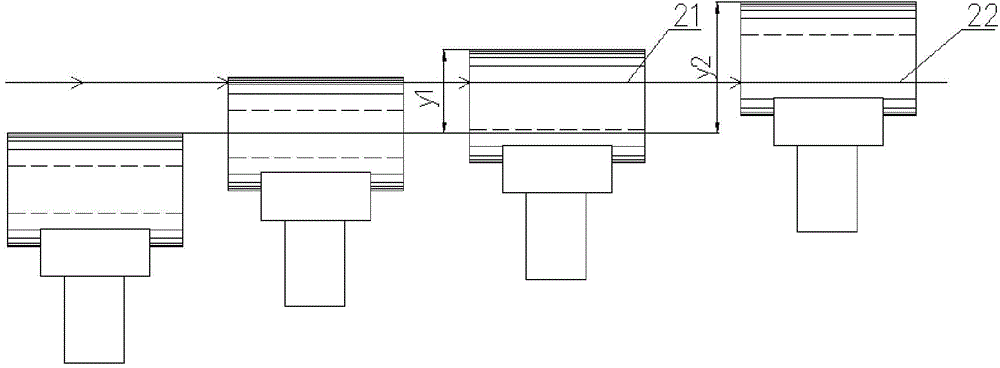

[0024] Such as figure 1 As shown, the coil height centering device provided by the present invention includes a coiling trolley 1 on which a saddle 11 for placing the coil 2 and a lifting device 12 for adjusting the height of the coil 2 are arranged. The winding trolley 1 is also provided with a lifting encoder 13 for recording the lifting height of the steel coil 2 by the lifting device and a limiter 14 for defining the mechanical zero point of the lifting device. The two sides of the moving track 15 of the rolling trolley 1 are respectively provided with a column 3, and a positioning light source 31 for emitting a concentrated light beam is provided on one side column, and the light source type is a grating; the other side column is provided with a positioning light source 31 for receiving emission. The light receiving device 32 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com