Welding method of air cooled condenser single row tube and tube plate employing carbon dioxide and argon mixed gas protection

An air-cooled condenser and carbon dioxide technology, which is applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of welding quality not meeting the requirements, welding process not meeting the requirements, welding seam strength and debris, etc. , to avoid solder bumps, small metal spatter, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

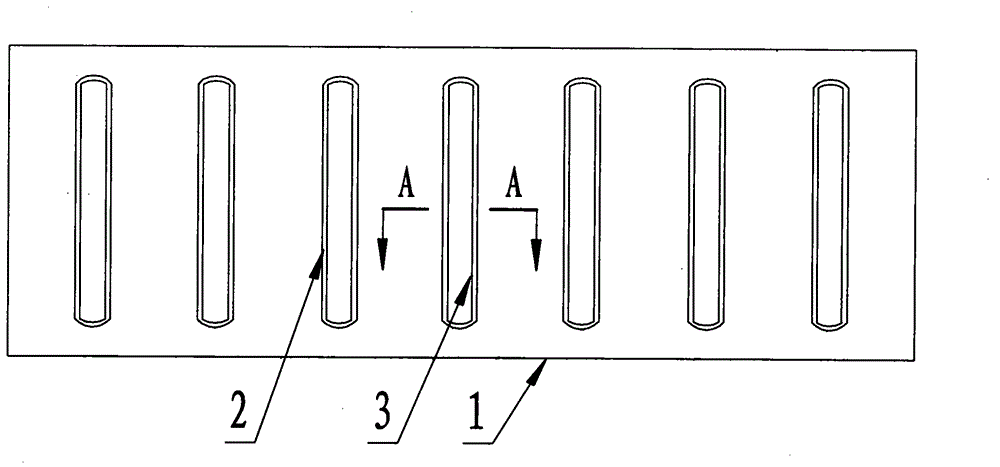

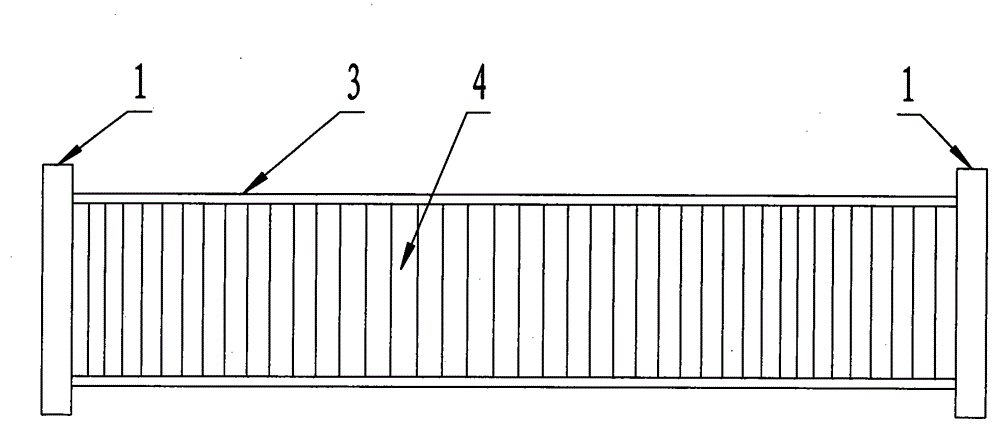

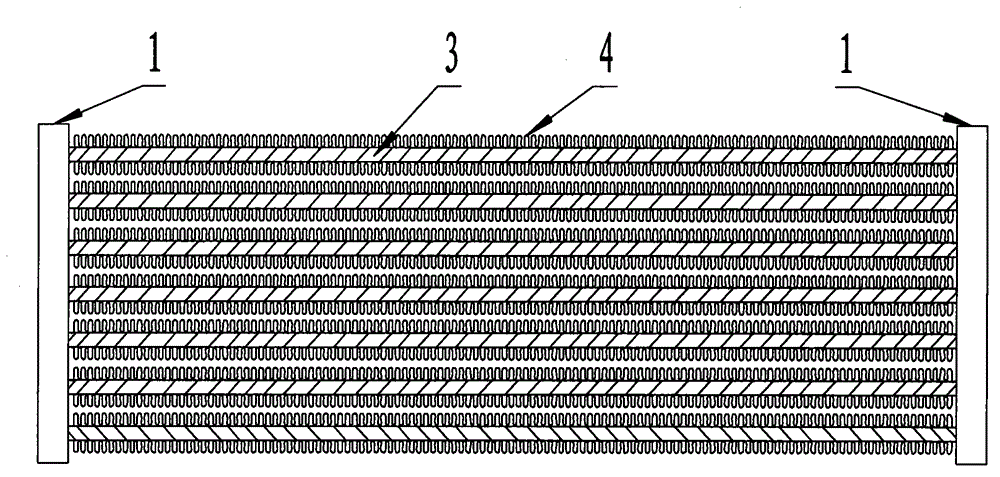

[0039] In the first step, the single-row tube 3 is installed on the tube plate 1, and at least five single-row tube mounting holes 2 are arranged side by side on the tube plate 1, and the distance between two adjacent single-row tube mounting holes 2 is equal, and the single-row tube The end faces of the two ends of the tube 3 are polished to be smooth, clean and free of dust. Remove the rust on the inner wall of the single-row tube installation hole 2 on the tube plate 1 to be welded. The two ends are inserted into the single-row tube installation holes 2 of the two tube plates 1, and the two sides of the single-row tube 3 are provided with cooling fins 4, and the end faces of the single-row tube 3 are arranged in the single-row tube installation holes 2, and the single-row tube 3 The distance between the end face of the row pipe 3 and the end face of the tube plate 1 is H, the end face of the single row pipe 3 and the inner wall of the single row pipe installation hole 2 form...

Embodiment 2

[0053] In the first step, the single-row tube 3 is installed on the tube plate 1, and at least five single-row tube mounting holes 2 are arranged side by side on the tube plate 1, and the distance between two adjacent single-row tube mounting holes 2 is equal, and the single-row tube The end faces of the two ends of the tube 3 are polished to be smooth, clean and free of dust. Remove the rust on the inner wall of the single-row tube installation hole 2 on the tube plate 1 to be welded. The two ends are inserted into the single-row tube installation holes 2 of the two tube plates 1, and the two sides of the single-row tube 3 are provided with cooling fins 4, and the end faces of the single-row tube 3 are arranged in the single-row tube installation holes 2, and the single-row tube 3 The distance between the end face of the row pipe 3 and the end face of the tube plate 1 is H, the end face of the single row pipe 3 and the inner wall of the single row pipe installation hole 2 form...

Embodiment 3

[0067] In the first step, the single-row tube 3 is installed on the tube plate 1, and at least five single-row tube mounting holes 2 are arranged side by side on the tube plate 1, and the distance between two adjacent single-row tube mounting holes 2 is equal, and the single-row tube The end faces of the two ends of the tube 3 are polished to be smooth, clean and free of dust. Remove the rust on the inner wall of the single-row tube installation hole 2 on the tube plate 1 to be welded. The two ends are inserted into the single-row tube installation holes 2 of the two tube plates 1, and the two sides of the single-row tube 3 are provided with cooling fins 4, and the end faces of the single-row tube 3 are arranged in the single-row tube installation holes 2, and the single-row tube 3 The distance between the end face of the row pipe 3 and the end face of the tube plate 1 is H, the end face of the single row pipe 3 and the inner wall of the single row pipe installation hole 2 form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com