Method for making pile leg of rice-shaped support pipe

A production method and a rice-shaped technology, applied in the direction of manufacturing tools, tubular objects, auxiliary devices, etc., can solve undiscovered problems, reduce difficulty, reduce production costs, and improve welding quality and welding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

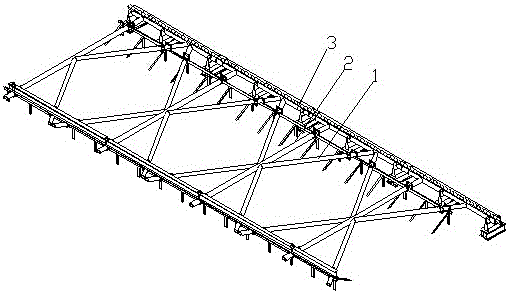

[0022] like figure 1 As shown, the invention discloses a method for manufacturing pile legs of a rice-shaped support pipe. The three-dimensional forming of the pile leg includes the bulk stage of the diagonal brace pipe and the production stage of the side piece. The tube 1 and the horizontal support tube 2 are made into a rice-shaped support tube assembly, and the components are welded during the production stage of the side piece 3, and finally three-dimensionally formed. The rice-shaped support tube assembly consists of a vertical horizontal support rod 2 and two It consists of two diagonal braces 1 on the side.

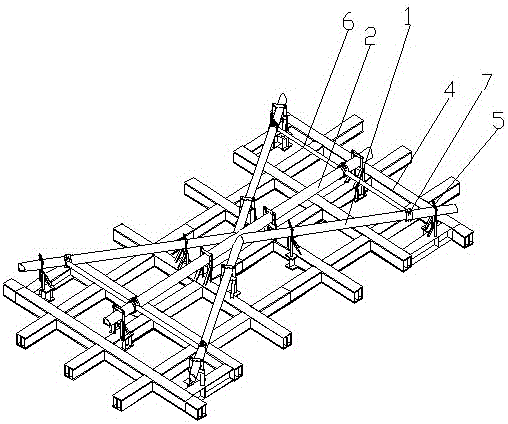

[0023] like figure 2 As shown, the specific steps of the manufacturing method of the above-mentioned rice-shaped support tube assembly are as follows:

[0024] S1. Welding bracket preparation: The welding bracket is composed of several criss-cross rods A4, and the bracket is provided with a number of support seats 5 for limiting and supporting the diagonal supp...

Embodiment 2

[0029] In this embodiment, on the basis of Embodiment 1, in step S2, the outer end of each diagonal strut is fixed to the adjacent horizontal strut by a holding rod, and the holding rod is composed of a rod body B6 and two ends of the rod body B6. Hoop 7 forms.

[0030] In this embodiment, the diagonal support pipe 1 and the horizontal support pipe 2 are fixed and locked by holding the rod, so as to avoid the deviation of the diagonal support pipe 1 and the horizontal support pipe 2 during welding, facilitate the welding operation, and improve the welding quality and welding efficiency. Holding rods 6 are arranged at both ends of the horizontal support pipe, and are fixed by holding rods and diagonal bracing rods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com