A monitoring device, a monitoring method, and an operation method of a data statistics module

A monitoring device and data module technology, which is applied in the field of monitoring devices, can solve problems such as inability to guarantee product quality, waste of labor, time-consuming and labor-intensive, etc., and achieve the effects of ensuring a first pass rate, reducing labor costs, and strengthening technology promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

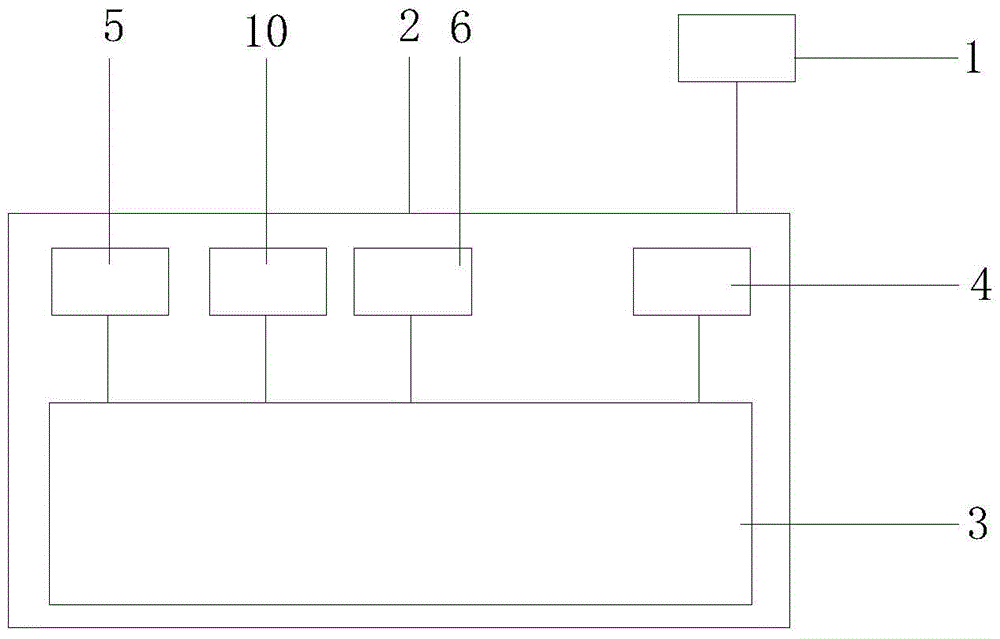

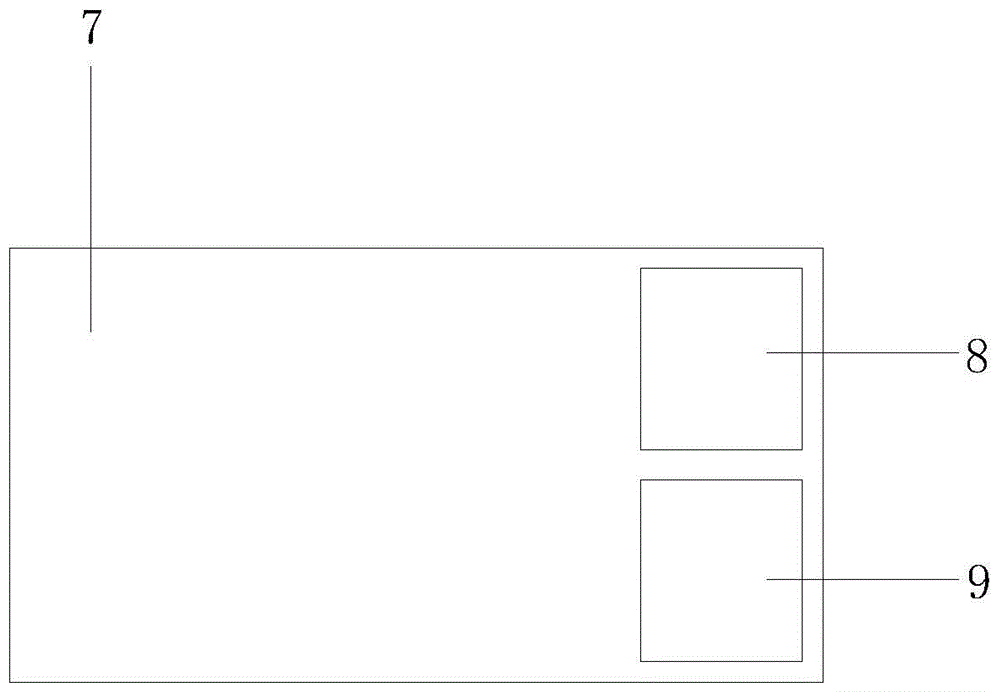

[0032] Example 1, such as Figure 1-2 As shown, a monitoring device according to an embodiment of the present invention includes: a monitoring device main body, the monitoring device main body includes a set of product transmission weighing device 1 and a control cabinet 2, and the control cabinet 2 is located in the Below the transmission weighing device 1; the control cabinet 2 includes an industrial computer PC3, the industrial computer PC3 is connected with a DC24V power switch 4, the industrial computer PC3 and the I / O data module one 5 and the I / O data Module two 6 are connected, and the mold cavity temperature measuring infrared probe 10 is also connected to the industrial computer PC3. A display 8 connected to the PC3, a barcode printer 9 is installed on the side of the operating table 7; a data statistics module, a drawing function module, and a data management module are embedded in the inside of the industrial computer PC. The first I / O data module uses an Advantec...

Embodiment 2

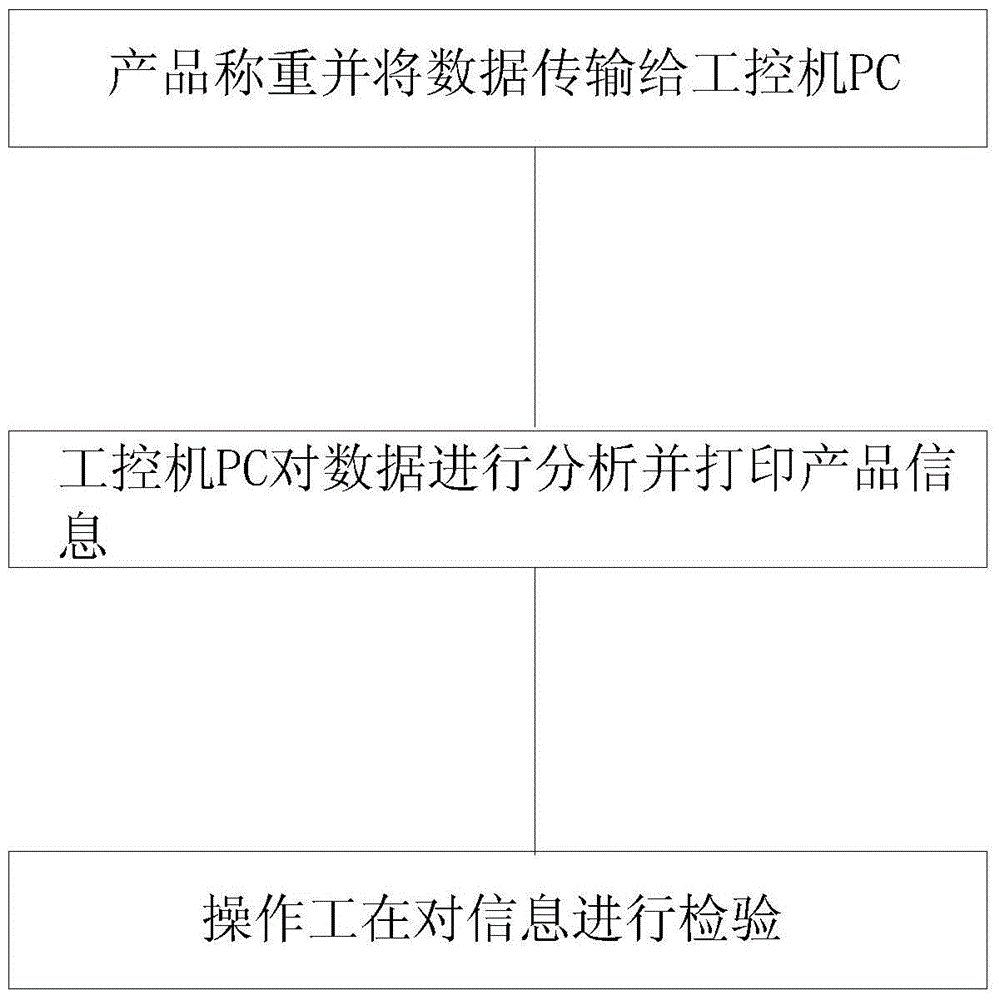

[0033] Example 2, such as image 3 Shown, the present invention also provides a kind of monitoring method, and this monitoring method comprises the following steps:

[0034] Step 101: weighing the product and transmitting the data to the industrial computer PC;

[0035] Step 102: the industrial computer PC analyzes the data and prints product information;

[0036] Step 103: The operator is checking the information.

[0037] Prevent the storage of defective products, ensure the first pass rate of products, improve production efficiency, ensure the stability of production rhythm and production process, reduce the scrap rate, and provide a guarantee for improving production efficiency.

[0038] Further, in step 101: the injection molded part is taken out of the injection molding machine by the robot and placed directly on the weighing device, and the weight data of the injection molded part is transmitted to the system in the industrial computer PC through the weighing device, ...

Embodiment 3

[0041] Example 3, such as Figure 4 Shown, a kind of operation method of data statistics module, this method comprises the following steps:

[0042] Step 1: Start the system first before starting production. The operator uses his job number as the user name. After entering his password, click OK to start the system, enter the main interface, and then select the corresponding product name, the system will automatically call corresponding parameters.

[0043] Step 2: After the system is ready, start the injection molding machine. After the injection molding machine closes the mold and discharges the material, it cools down to the time and opens the mold to the end. The manipulator takes away the injected finished product. The infrared temperature measuring probe records the temperature of the mold cavity at this time. The temperature is transmitted to the system in the industrial computer through I / O data module 1 and I / O data module 2. The system will compare the temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com