A kind of manufacturing method of high-strength offset printing color plate

A production method and high-strength technology, applied in the direction of mechanical processing/deformation, etc., can solve the problems of long storage time, softening of cardboard, prolonging the delivery cycle, etc., achieve the improvement of physical indicators, increase the strength of cardboard, and prevent cardboard from warping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

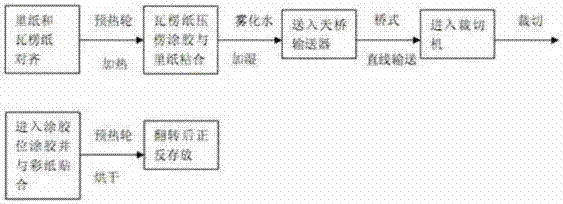

[0022] Such as figure 1 As shown, the present invention provides a high-strength three-layer offset printing color plate manufacturing method, the main steps include: (1) install the rolls used for the inner paper and corrugated paper on the base paper support, align the inner paper and corrugated paper , the aligning device for lining paper and corrugated paper is infrared photoelectric induction, and the traditional one is empirical alignment, which improves the alignment accuracy; (2) The aligned lining paper and corrugated The baking of lining paper and corrugated paper protects paper fibers from excessive damage, and at the same time provides paper fiber components that meet the requirements for subsequent production processes. The diameter of the preheating wheel in the traditional processing technology is more than 1000mm. Using the traditional preheating wheel can achieve the paper performance effect of the subsequent production process after preheating. (3) The prehe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com