Speed boat

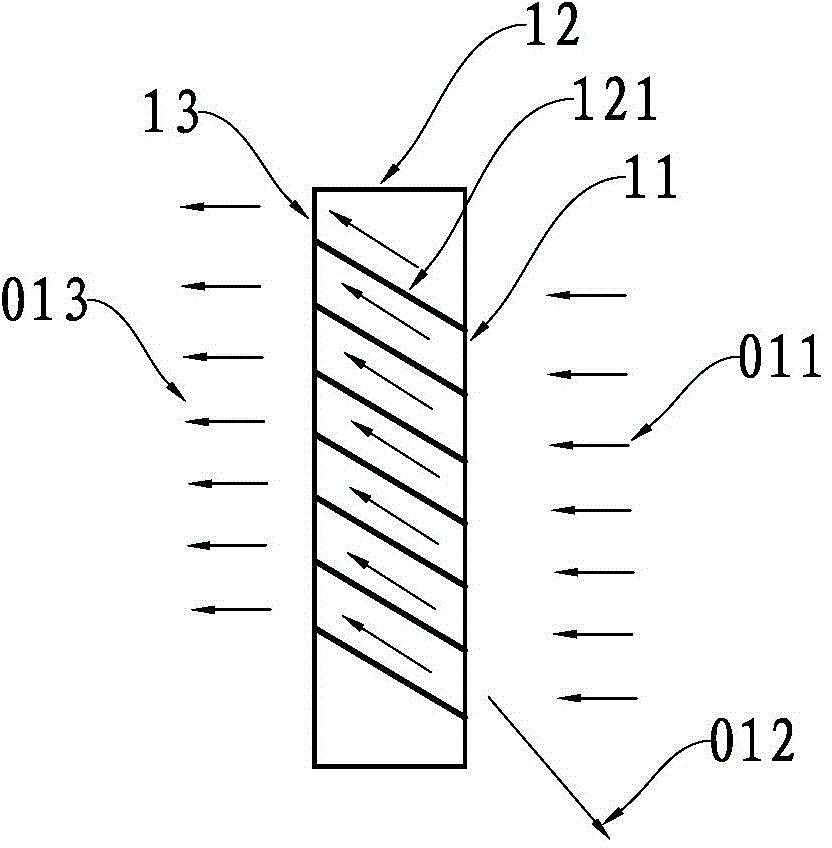

A technology for speedboats and hulls, which is applied to ships, ship parts, auxiliary equipment, etc., can solve the problems of normal operation, reduce the effective area of the fluid channel of the water-air separation device 12, and reduce the speed of the speedboat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

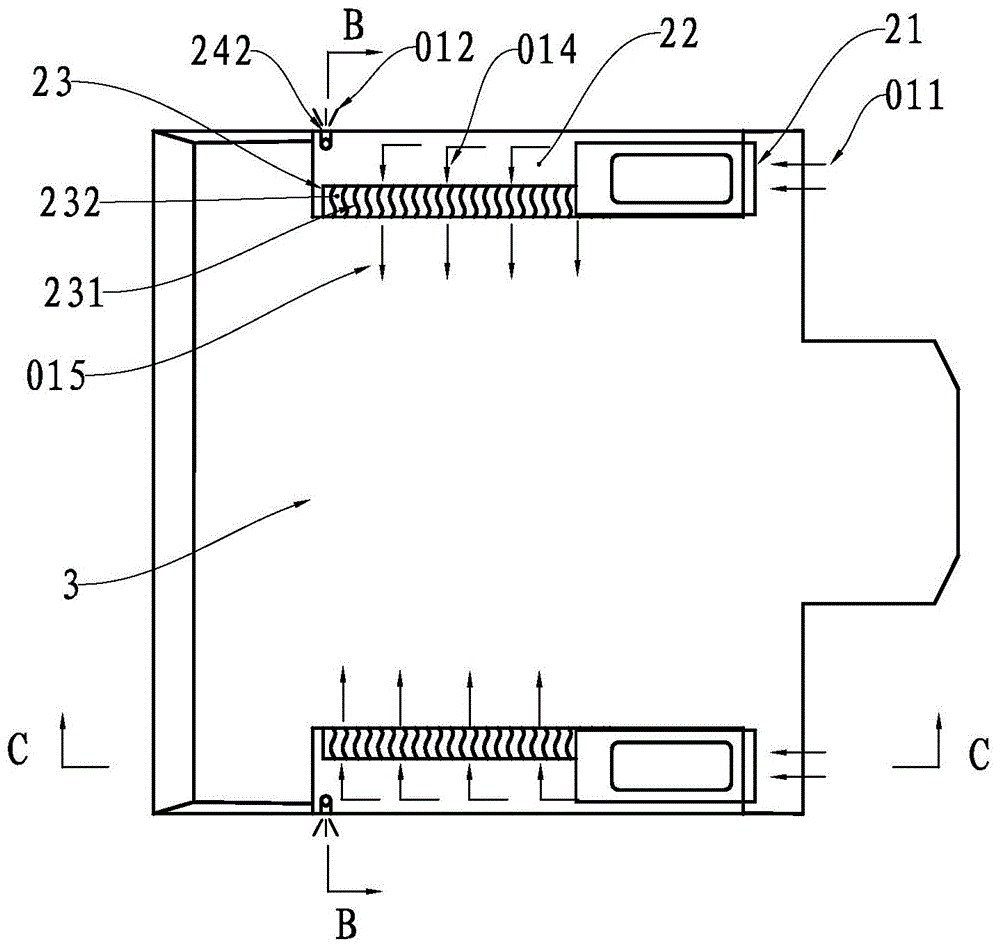

[0028] The speedboat in this example has a hull and engine room ventilation system, and the engine room ventilation system is used to supply air to the engine room to meet the oxygen consumption demand of the internal combustion engine and the cooling demand of the equipment in the engine room.

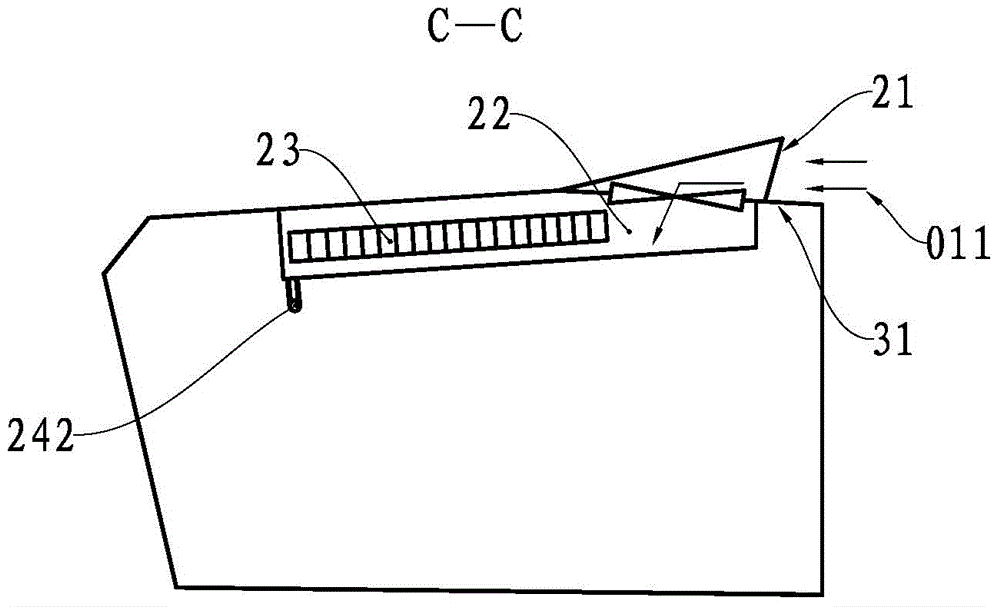

[0029] see Figure 2 to Figure 4 , The engine room ventilation system is composed of two ventilation units located symmetrically on both sides of the hull. The ventilation unit is composed of an inlet 21, a settling device 22, a water-air separation device 23, a drainage device and an outlet. The inlet 21 is located on the engine room deck 31 and the opening faces the bow of the boat. The settling device 22 is a chamber attached to the narrow and long structure on the inside of the side of the engine room. The water and air separation device 23 is located on the side of the settling device 22 away from the side, and it is composed of a plurality of S-shaped water baffles 231 arranged...

no. 2 example

[0037] As an explanation of the second embodiment of the present invention, only the differences from the above-mentioned first embodiment will be described below.

[0038] see Figure 6 , the fluid channel formed between two adjacent water barriers 431 of the water-gas separation device has a C-shaped bend 4321, and the fluid 014 will change its traveling direction at the bend 4321, and the water in it will collide with the water barrier under the action of centrifugal force. Gathered on the side wall of the plate 431.

[0039] In this example, the area of the inlet of the fluid channel is the sum of the effective cross-sectional areas 032 of all individual fluid channels.

no. 3 example

[0041] As a description of the third embodiment of the present invention, only the differences from the above-mentioned first embodiment will be described below.

[0042] see Figure 7 The fluid channel formed between two adjacent water baffles 531 of the water-air separation device has three bends, so that the moisture in the fluid 014 is subjected to centrifugal force three times, thereby reducing the moisture content of the air 015 entering the cabin.

[0043] In this example, the area of the inlet of the fluid channel is the sum of the effective cross-sectional areas 033 of all individual fluid channels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com