Method for improving hard water resistance of magnesium aluminum silicateinorganic gel

A magnesium aluminum silicate and inorganic gel technology, which is applied in the field of improving the hard water resistance of magnesium aluminum silicate inorganic gel, can solve problems such as decline, collapse of "card palace" network structure, thixotropy of gel products, etc., to achieve Effects of extended application range, low cost, and increased dispersion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

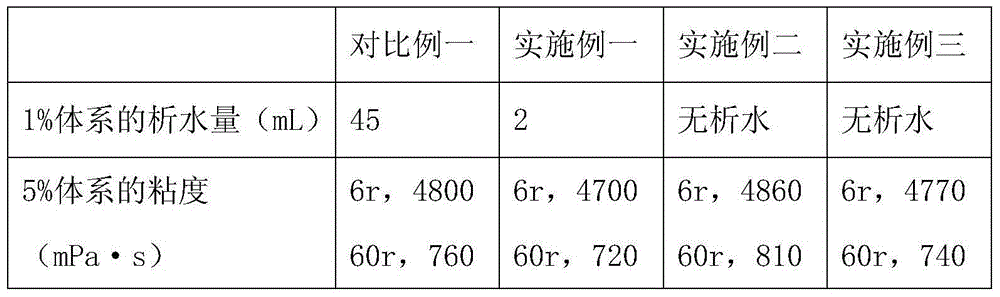

Embodiment 1

[0023] A method for improving the hard water resistance of magnesium aluminum silicate inorganic gel, comprising the following steps: adding 1kg of magnesium aluminum silicate inorganic gel powder and 100g of sodium citrate into a mixer, stirring at a high speed, and heating up while stirring to 60°C, keep for 15 minutes, and cool to room temperature to obtain the modified product.

Embodiment 2

[0025] A method for improving the hard water resistance of magnesium aluminum silicate inorganic gel, comprising the following steps: adding 1kg of magnesium aluminum silicate inorganic gel powder and 100g of sodium oxalate into a mixer, stirring at a high speed, and heating up to Keep at 60°C for 15 minutes, and cool to room temperature to obtain the modified product.

Embodiment 3

[0027] A method for improving the hard water resistance of magnesium aluminum silicate inorganic gel, comprising the steps of: adding 1kg of magnesium aluminum silicate inorganic gel powder, 80g of sodium oxalate, and 20g of sodium citrate into a mixer, and stirring at a high speed, Raise the temperature to 60°C while stirring, keep it for 15 minutes, and cool to room temperature to obtain the modified product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com