Method for preparing steviol

A technology of steviol and steviol glycosides, which is applied in the field of synthesis of natural compounds, can solve the problems of difficult recovery, easy inactivation, unavoidable high price of biological enzymes, etc., and achieve the effect of easy separation and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

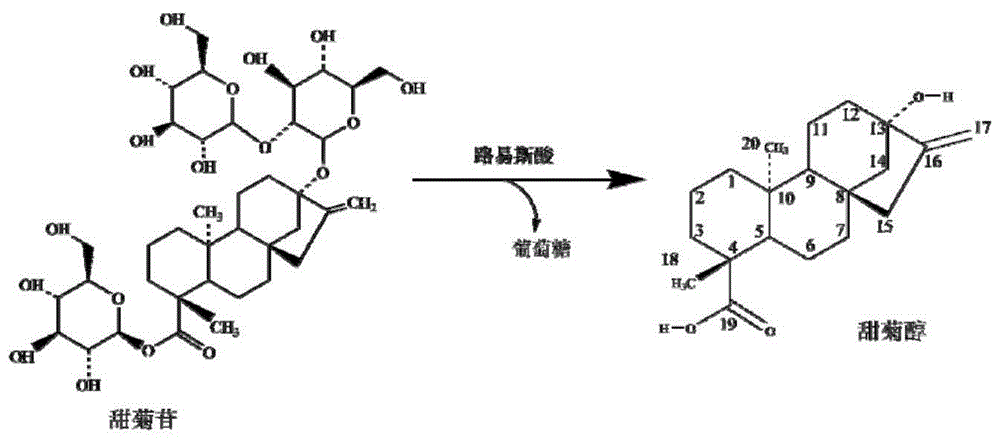

Image

Examples

Embodiment 1

[0014] Stevioside St was prepared as a 5 mg / mL aqueous solution, kept at 50°C for 0.5 h, and 0.5 mmol / g St ferric chloride (dissolved in water) was added. After 24 h of reaction, a large amount of white precipitates were formed. After suction filtration, washing with water, and second recrystallization from methanol, steviol can be obtained. The number of moles of glucose generated is three times the number of moles of stevioside St. As determined by HPLC, the conversion rate of St was 98.0%, the yield of steviol was 85%, and the purity was 98.5%. 13 CNMR (400MHz, Pyr), 41.6(C1), 20.4(C2), 39.2(C3), 44.4(C4), 57.5(C5), 23.2(C6), 42.4(C7), 42.4(C8), 54.8(C9 ),40.4(C10),21.3(C11),41.2(C12),80.9(C13),48.0(C14),48.6(C15),158.3(C16),103.4(C17),29.9(C18),180.6(C19 ), 16.2(C20); 1 H NMR (400MHz, Pyr), δ14.70 (s, 1H, H-19), 5.49 (dd, J=3.9, 2.3Hz, 1H, H-17), 5.04 (d, J=1.6Hz, 1H, H-17).

Embodiment 2

[0016] Ferric chloride was replaced by aluminum chloride and cuprous chloride of the same molar number, and all other experimental conditions were the same as in Example 1. After 24 hours of reaction, the conversion rates of St were 84.5 and 65.0%, respectively.

Embodiment 3

[0018] Rebaudioside A was formulated into a 50mg / mL aqueous solution, kept at a constant temperature of 0.5h at 85°C, added 1mmol / g Reb A in an aqueous ferric chloride solution, and reacted for 12h. The conversion rate of Reb A was determined to be 85.0% by HPLC, and that of steviol was Yield 96.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com