Two-step induction heater of bent tube for oil gas pipeline production, and method thereof

An induction heating device, oil and gas pipeline technology, applied in heat treatment furnaces, heat treatment equipment, improvement of process efficiency, etc., can solve the problems of difficult to guarantee the performance of elbows, low production efficiency, large ovality, etc., and achieve small deformation and production efficiency. The effect of high and small ovality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

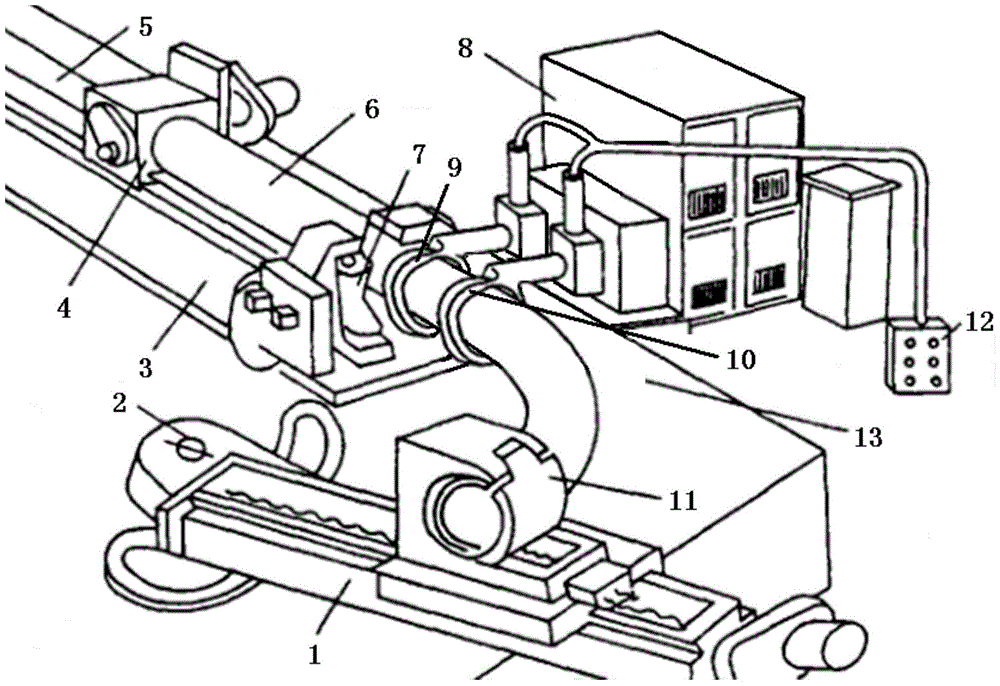

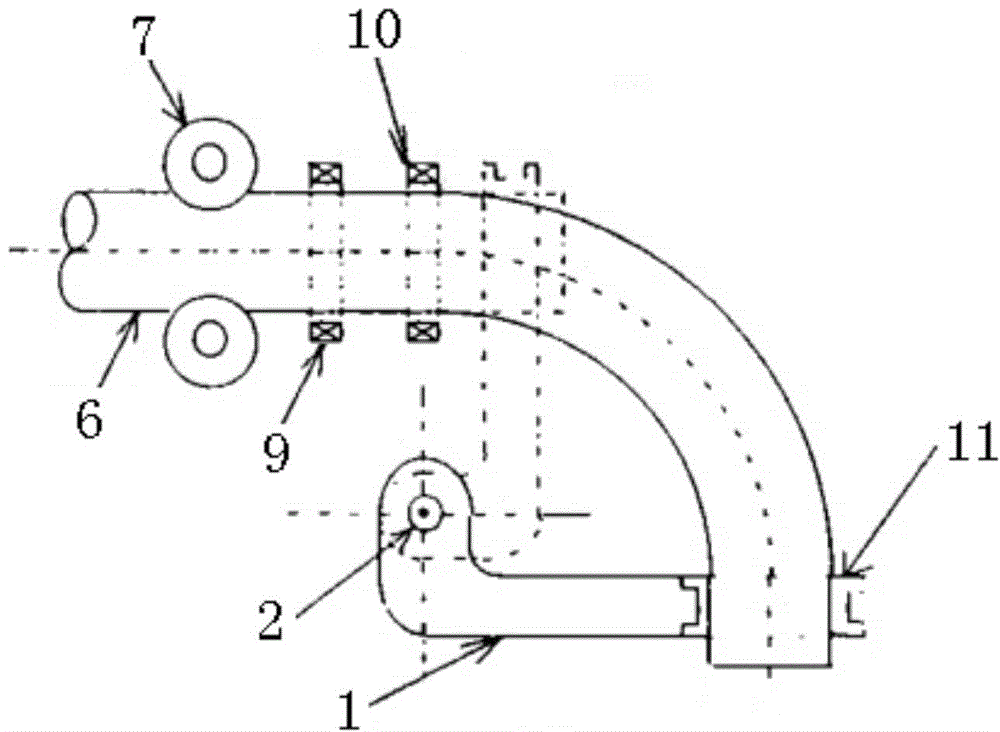

[0033] Pipe specification: LSAW pipe, steel grade X70. Its bending steps are:

[0034] 1) Place the pipe on the fuselage 3 and set it in the first and second induction coils. The distance between the first and second induction coils is 100mm, and fix the tail of the pipe on the tailstock 4. Through the main drive device 5 Push the pipe 6;

[0035] 2) During the pipe pushing process, when the part of the pipe to be bent moves to the first induction coil 9, the pipe is heated to 650°C through the first induction coil, wherein the frequency of the first induction coil is 800Hz and the power is 1200kw , the voltage is 650V, and the width of the heating belt is 35mm. Then when the preheated part to be bent moves to the second induction coil 10, the pipe is heated to 980°C through the second induction coil, wherein the frequency of the second induction coil is 1000Hz, the power is 1200kw, and the voltage is 650V. The width of the heating belt is 30mm. While the second inductio...

Embodiment 2

[0041] Pipe specification: LSAW pipe, steel grade X80. Its bending steps are:

[0042] 1) Place the pipe on the fuselage 3 and put it in the first and second induction coils. The distance between the first and second induction coils is 60mm, and fix the tail of the pipe on the tailstock 4, and pass through the main drive device 5 Push the pipe 6;

[0043] 2) During the pipe pushing process, when the part of the pipe to be bent moves to the first induction coil 9, the pipe is heated to 700°C through the first induction coil, wherein the frequency of the first induction coil is 850Hz and the power is 1300kw , the voltage is 700V, and the width of the heating belt is 35mm. Then when the preheated part to be bent moves to the second induction coil 10, the pipe is heated to 950°C through the second induction coil, wherein the frequency of the second induction coil is 1000Hz, the power is 1300kw, and the voltage is 650V. The width of the heating belt is 30mm. While the second ...

Embodiment 3

[0049] Pipe specification: LSAW pipe, steel grade X60. Its bending steps are:

[0050] 1) Place the pipe on the fuselage 3 and put it in the first and second induction coils. The distance between the first and second induction coils is 30mm, and fix the tail of the pipe on the tailstock 4, and pass through the main drive device 5 Push the pipe 6;

[0051] 2) During the pipe pushing process, when the part of the pipe to be bent moves to the first induction coil 9, the pipe is heated to 550°C through the first induction coil, wherein the frequency of the first induction coil is 500Hz and the power is 600kw , the voltage is 400V, and the width of the heating belt is 38mm. Then when the preheated part to be bent moves to the second induction coil 10, the pipe is heated to 930°C through the second induction coil, wherein the frequency of the second induction coil is 800Hz, the power is 600kw, and the voltage is 400V. The width of the heating belt is 25 mm. While the second in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com