Relating to the stretch-in elastic threader for silk reeling machine

A technology of thread collector and silk reeling machine, which is applied in the direction of silk reeling, etc., can solve the problem that the thread collector cannot block the knots, etc., and achieves the effects of small changes, improved uniformity, and convenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

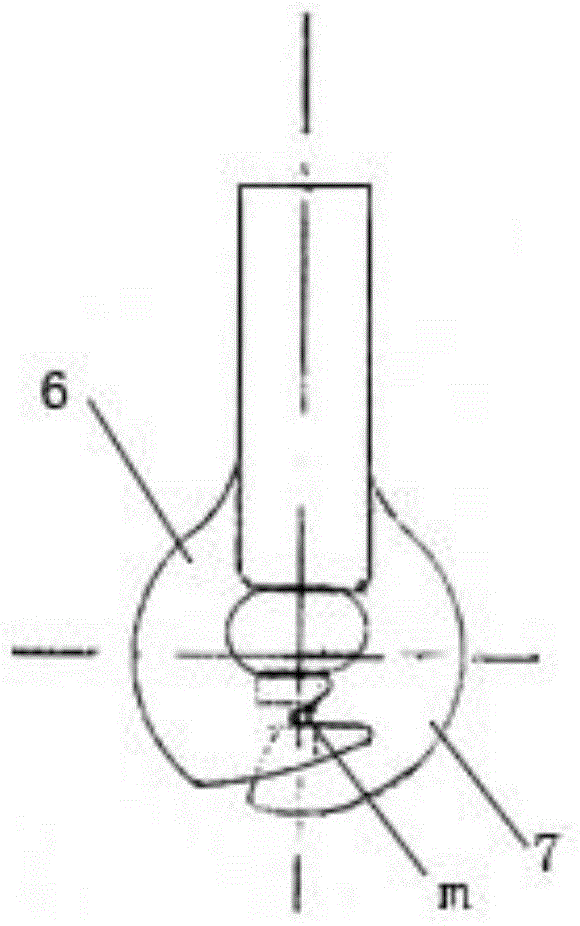

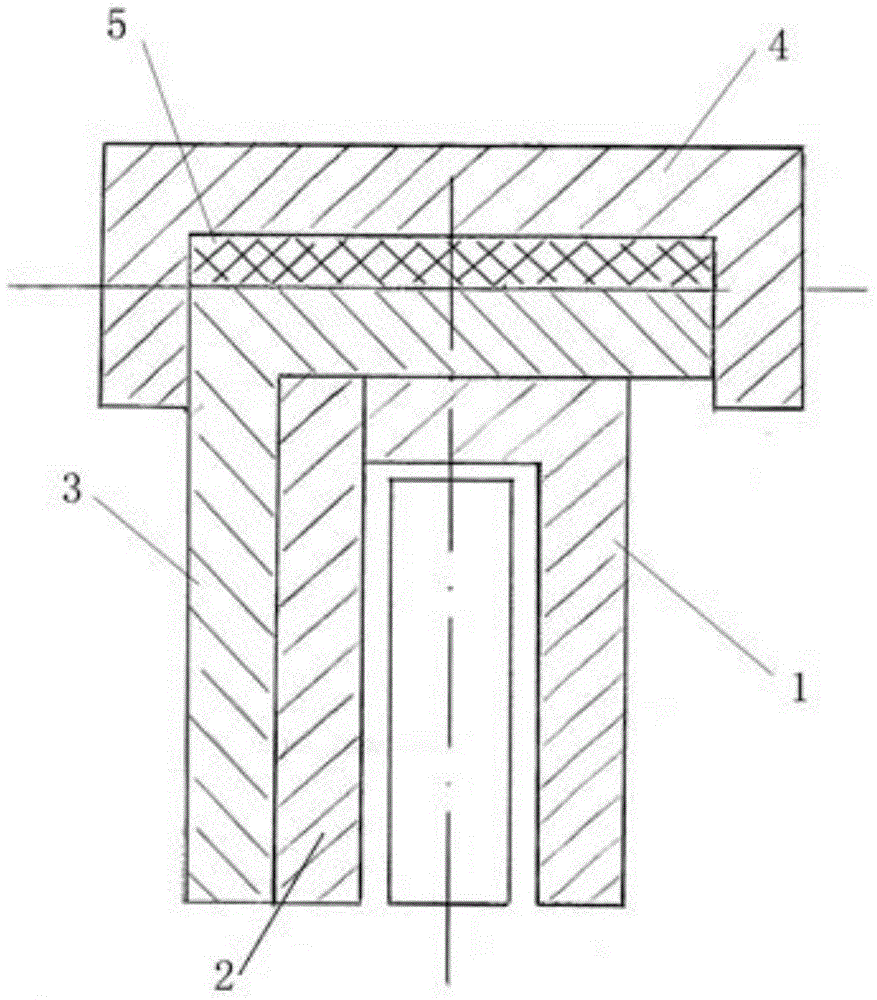

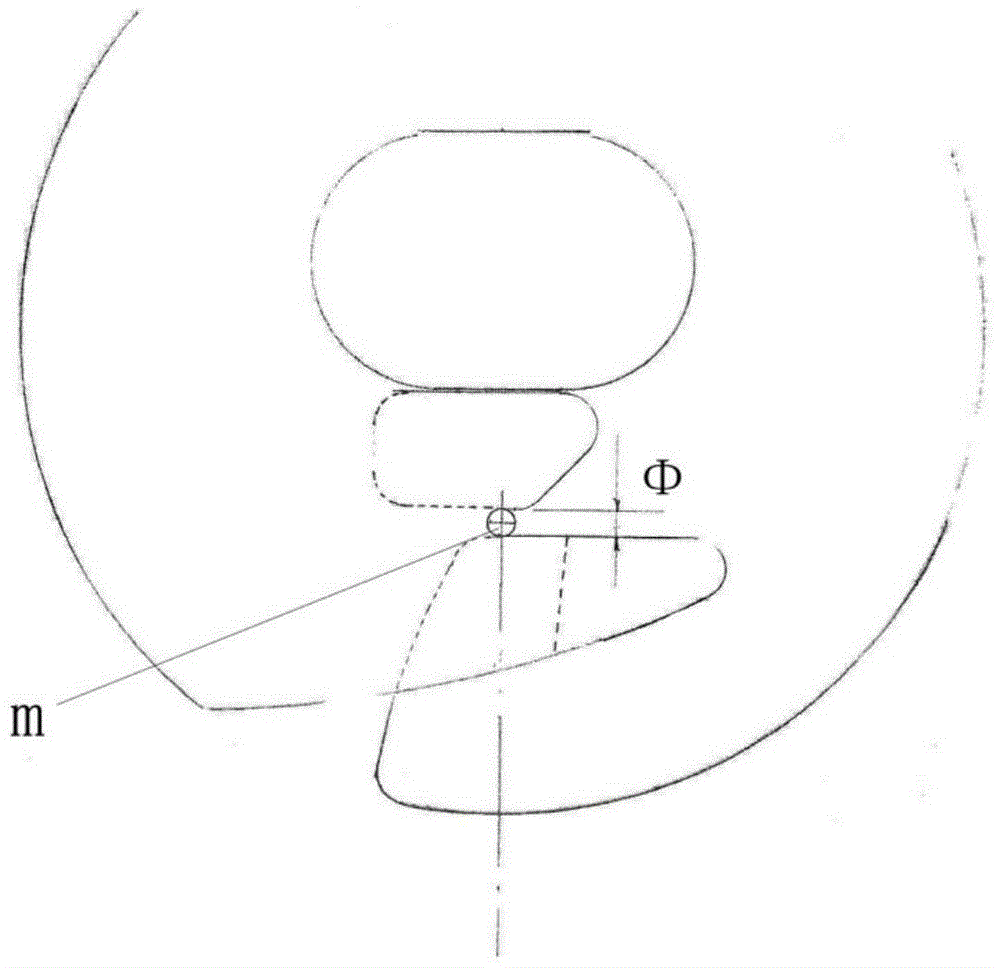

[0033] The thread collector is composed of an upper block and a lower block as follows: figure 1 As shown, the upper and lower baffles are made of high-strength stainless steel springs, and the upper baffle is composed of a rectangular stainless steel spring smoothly connected with a semicircular spring. The structure of the upper baffle is as follows Figures 5 to 7 as shown, Figure 5 Middle: a is the first concave hole, b is the first thread-through groove, c is the hooker, d is the semicircle at the bottom of the upper block, and i is the chamfer of the upper block; the first concave hole a It is a clean work area through the air, and the thread inlet of the upper block is provided with a thread entry chamfer i, and the thread entry chamfer i is provided with a β angle, and the β angle forms a wedge shape with the bottom block, and the thread Only then can the flap be opened under the action of tension, and the upturned angle α of the upturned hook-in device is 15° to 45°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com