An installation and construction method of hdpe steel-plastic composite spiral winding drainage pipe

A spiral winding and construction method technology, which is applied in pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve problems such as poor water resistance, easy leakage, brittle connections at thermal expansion and contraction joints, etc. To achieve the effect of guaranteed strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Various embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

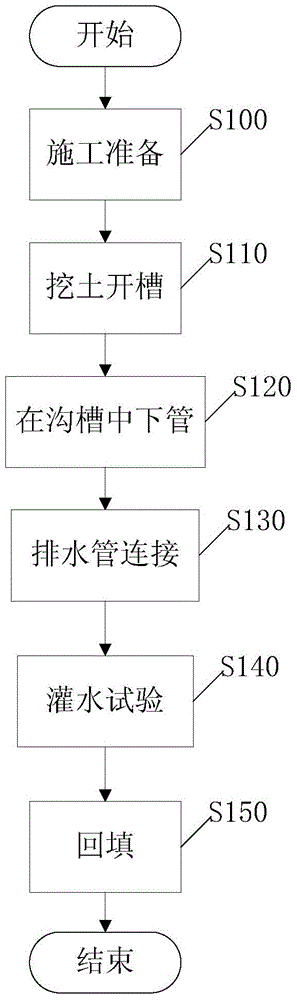

[0012] figure 1 Shown is the flow chart of the HDPE steel-plastic of the present invention conforming to the installation and construction method of the spirally wound drainage pipe, as shown in the figure, the method comprises the following steps:

[0013] First, in step S100, construction preparation, specifically, before installation of the HDPE steel-plastic composite spiral-wound drainage pipe, check its appearance and the tolerance of the joint fit, eliminate the dirt and sundries inside and outside the drainage pipe and pipe fittings, and the construction site and When the temperature difference of the material storage place is large, the drainage pipe and pipe fittings should be placed on site for a certain period of time before installation, so that the temperature is close to the ambient temperature of the construction.

[0014] After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com