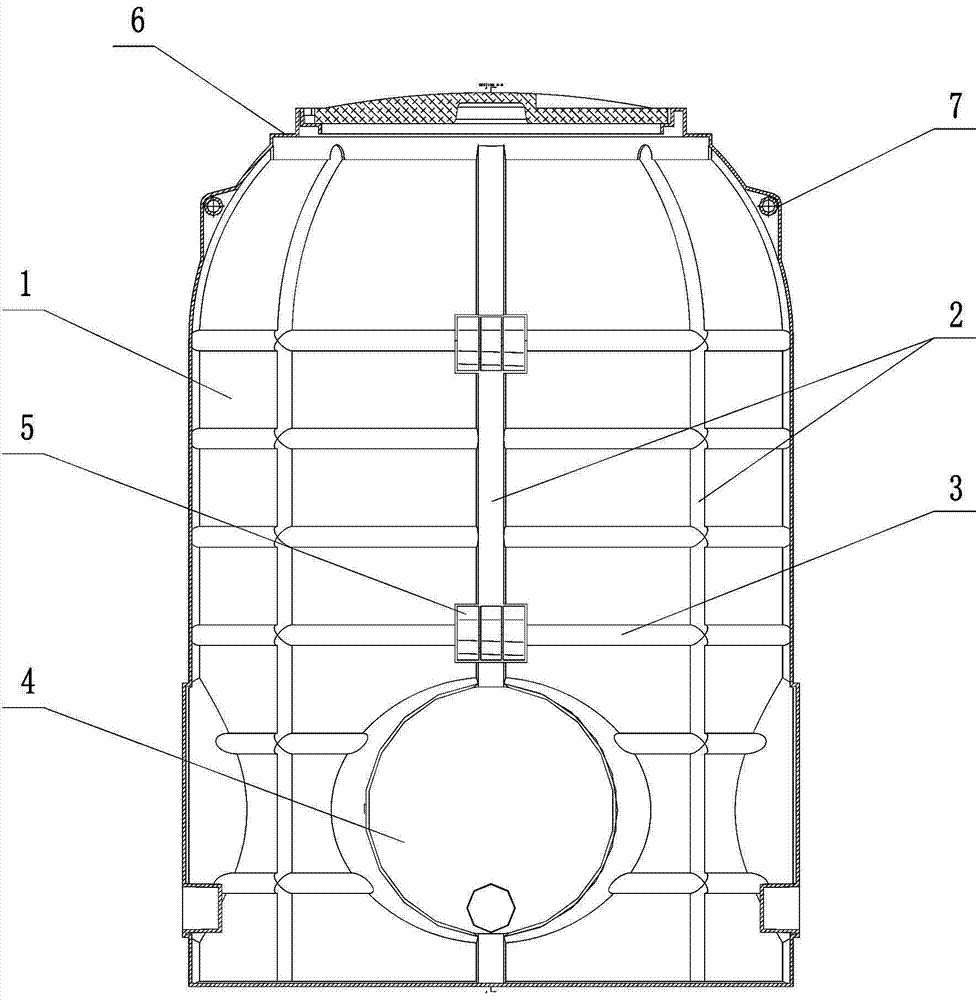

Integrated anti-settling valve inspection well

An anti-subsidence and inspection well technology, applied in artificial islands, underwater structures, buildings, etc., can solve problems such as a large number of labor costs, inconvenient maintenance, water pollution, etc., to improve construction efficiency, simple connection, and solid structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

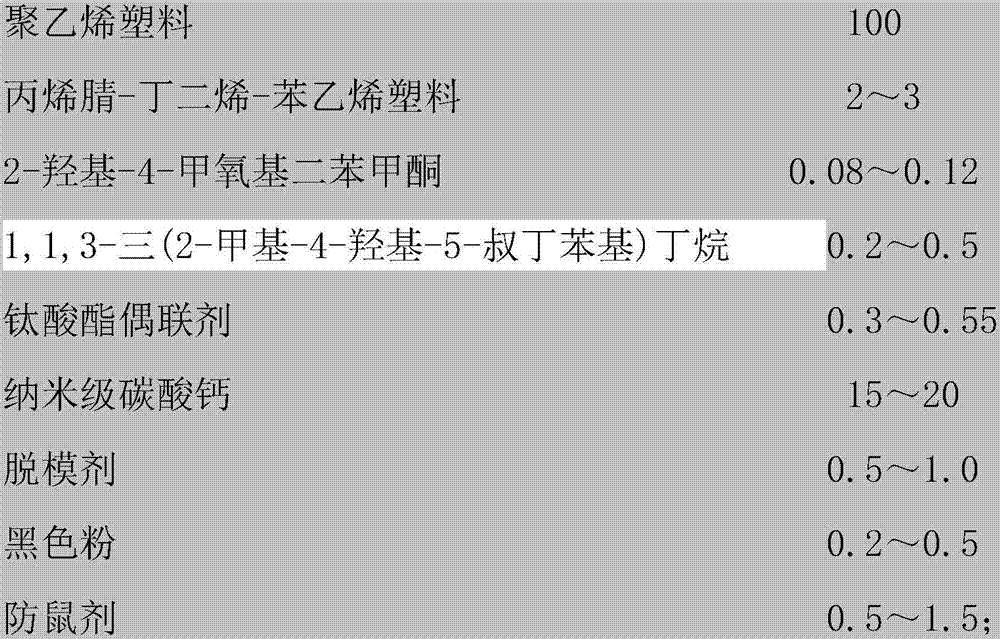

Embodiment 1

[0028] The present invention constitutes the plastic formula of product:

[0029]

[0030]

[0031] The PE plastic material for manufacturing the valve inspection well is pulverized, and the particle size is two kinds of powdery plastics, 15 mesh and 50 mesh.

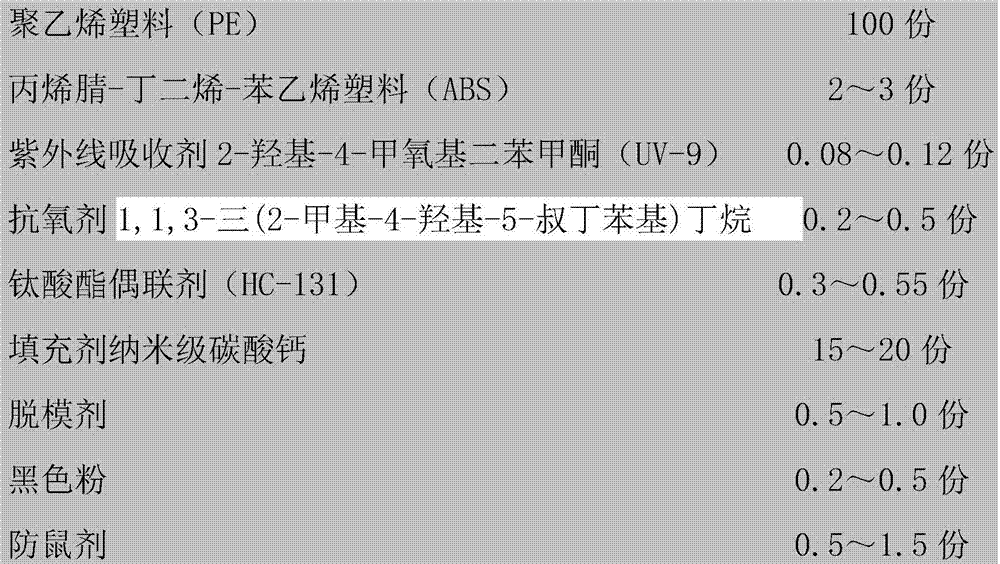

Embodiment 2

[0033] The present invention constitutes the plastic formula of product:

[0034]

[0035] The PE plastic material used to manufacture the valve inspection well is pulverized, and the particle size is two kinds of powdery plastics, 30 mesh and 35 mesh.

Embodiment 3

[0037] The present invention constitutes the plastic formula of product:

[0038]

[0039]

[0040] The PE plastic material used for manufacturing the valve inspection well is pulverized, and the particle size is two kinds of powdery plastics, 25 mesh and 40 mesh.

[0041] The manufacture method of well body 1 of the present invention has following steps:

[0042] 1. Mold design: Design axial and longitudinal grooves in the inner cavity of the well body mold, design the mold mouth with a structural mold that matches the well head, and design a straight pipe that matches the shape of the branch pipe under the well body mold mold;

[0043] 2. Accounting weight: Calculate the raw material weight M of the production valve inspection well according to the surface area S of the well body:

[0044] ①M=ρ×s×e

[0045] ②S=(πr 1 2 +2πr 1 h+πr 2 2 )*k

[0046] Among them: ρ - raw material density, about 0.93g / cm 3 ; e—well wall thickness; r 1 —well body radius; r 2 —well...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com