Novel high-efficiency BOG recovery system with cold storage function

A recovery system, condensation recovery technology, applied in pipeline systems, container discharge methods, equipment loaded into pressure vessels, etc., can solve problems such as incomplete operation reliability, achieve good industrial promotion and market application prospects, reduce The effect of capital investment and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The implementation of the present invention will be further described below in conjunction with the accompanying drawings and examples, but the implementation and protection of the present invention are not limited thereto.

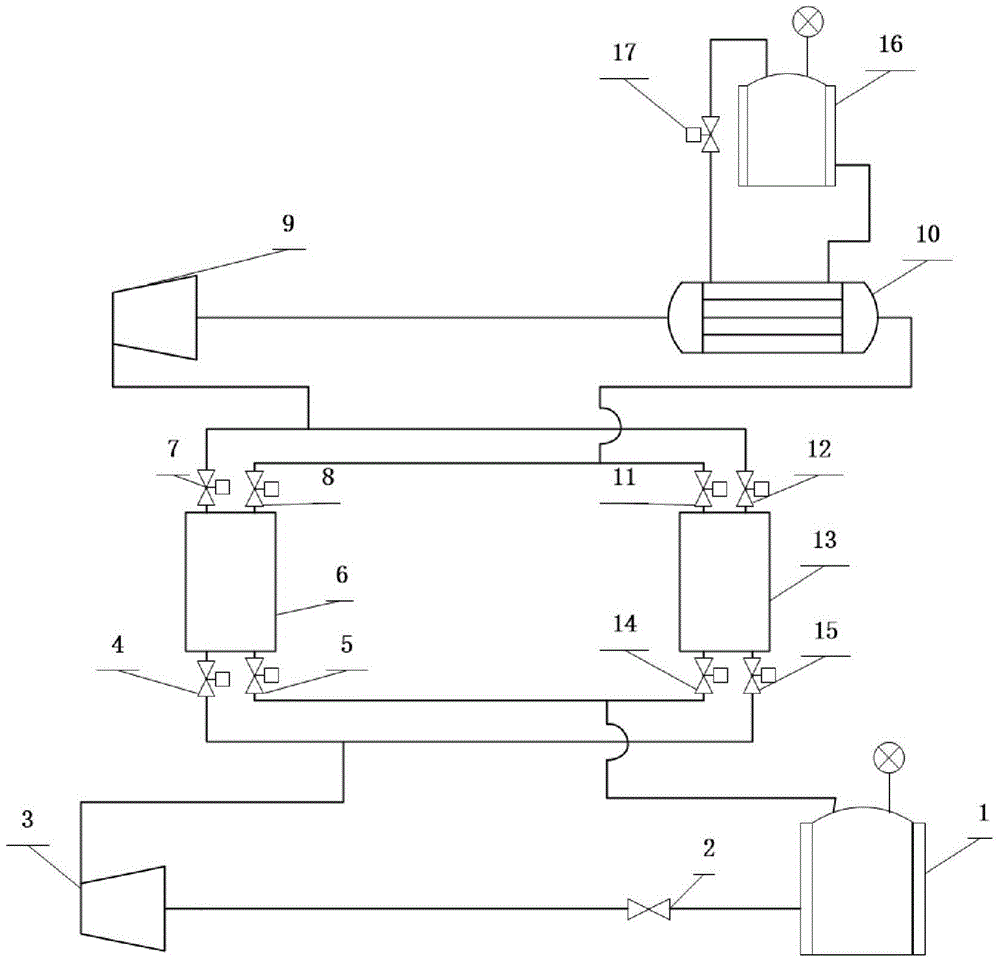

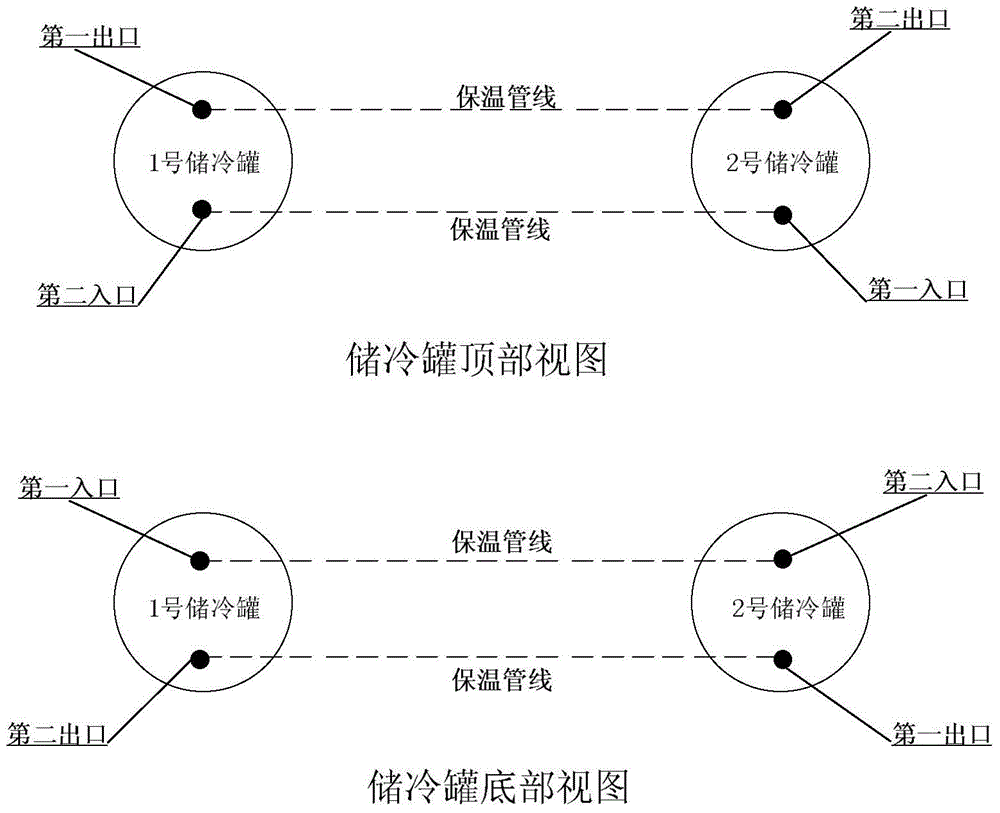

[0015] This embodiment describes in detail a new type of BOG recovery process and device with high efficiency, low energy consumption and cold storage function. This BOG recovery system compresses the nitrogen from the nitrogen storage tank to obtain compressed nitrogen, and then flows through the cold storage tank (previously stored in the pre-cooling preparation stage) for cooling. After the temperature is lowered, it enters the expander for expansion, and then enters the The BOG condensation recovery device exchanges heat with the BOG gas to make it liquefied, then flows through another cold storage tank, and finally enters the nitrogen storage tank after the temperature rises.

[0016] Such as figure 1 As shown, the BOG recovery system of this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com