Assembly of an aluminum component and of a steel component having a ZnAlMg alloy coating

A metal coating, component technology, applied in the field of assembly of aluminum-based components and steel components, which can solve problems such as low corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

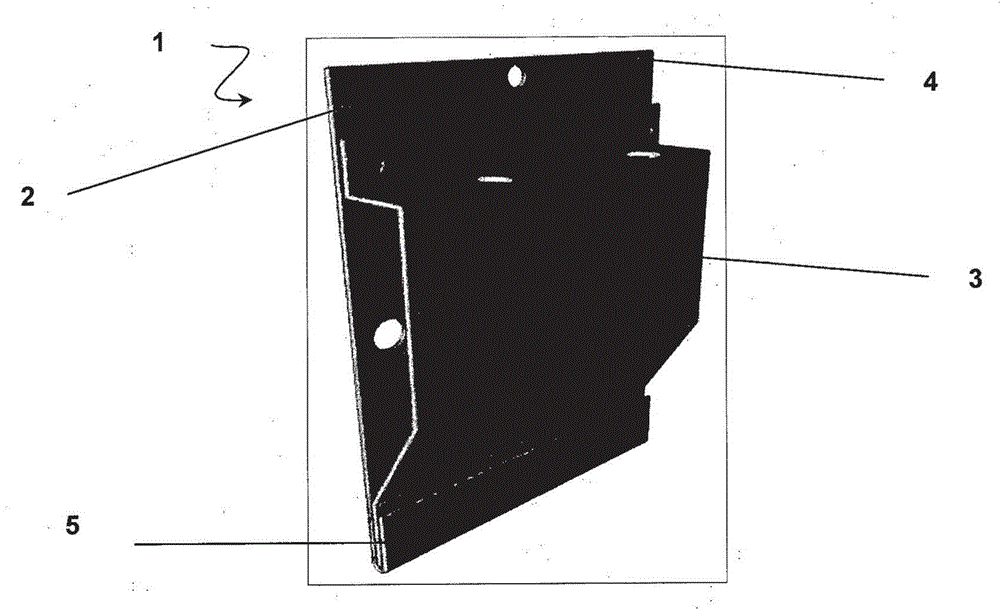

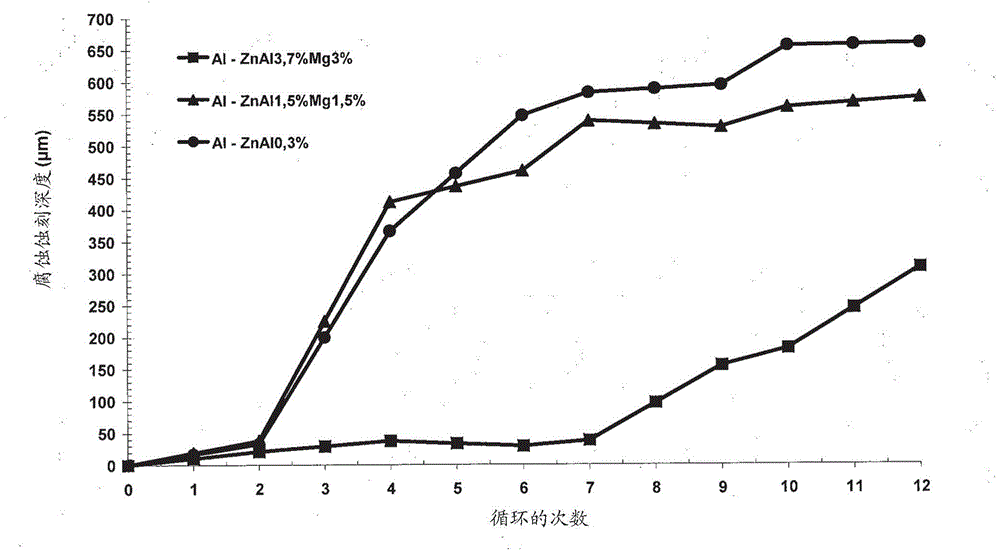

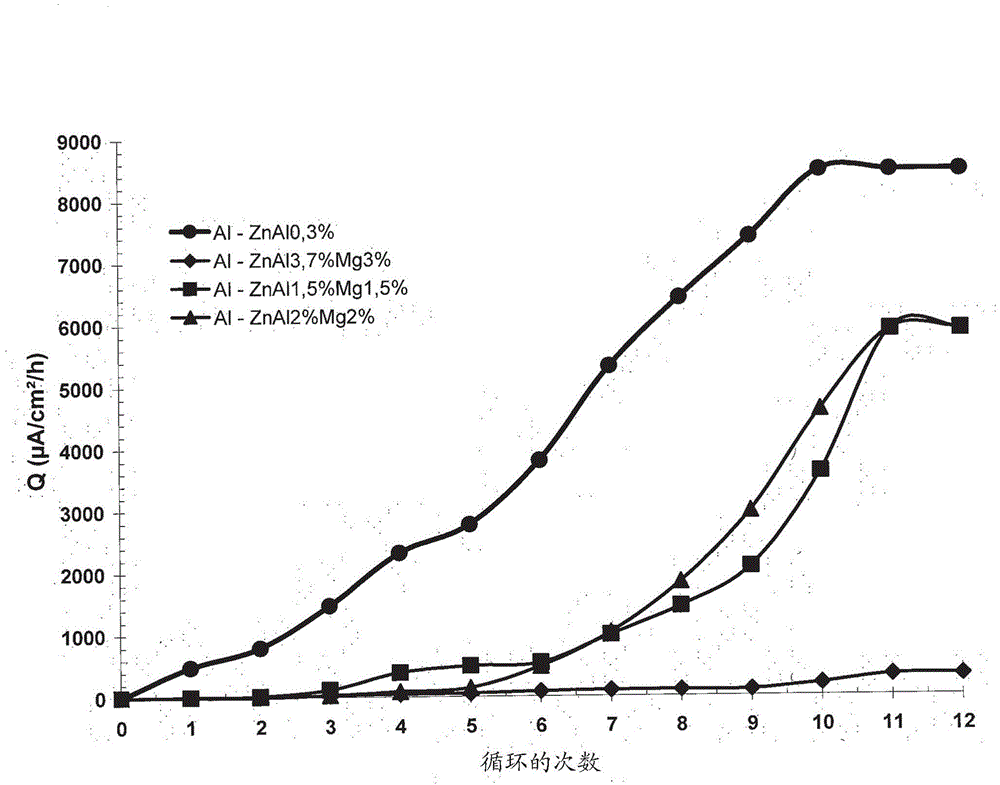

[0036] For the examples in all detailed implementations, assemblies of panels made of aluminum AA6061 and steel sheets coated with a variable composition aluminium-zinc-(magnesium) alloy were used to construct assembly samples, wherein the coating had Uniform thickness of 7.5 μm.

[0037] These assemblies consisted of a first coated steel plate measuring 10 cm wide and 20 cm high. The process involved the assembly of bonded aluminum panels with dimensions 10 cm wide, 4 cm high and 1 mm thick. An aluminum plate is placed at the center of the steel plate with a separation of 120 μm between the two plates due to the presence of the adhesive, simulating an assembly such as a door of a motor vehicle. The active area with two uncoated sides facing each other had dimensions of 6 cm wide and 4 cm high. A copper wire connects the two sides so that the two sides are in electrical contact, thus enabling simulation of galvanic corrosion in the active area.

[0038] The inactive areas o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com