A comprehensive flue gas treatment system

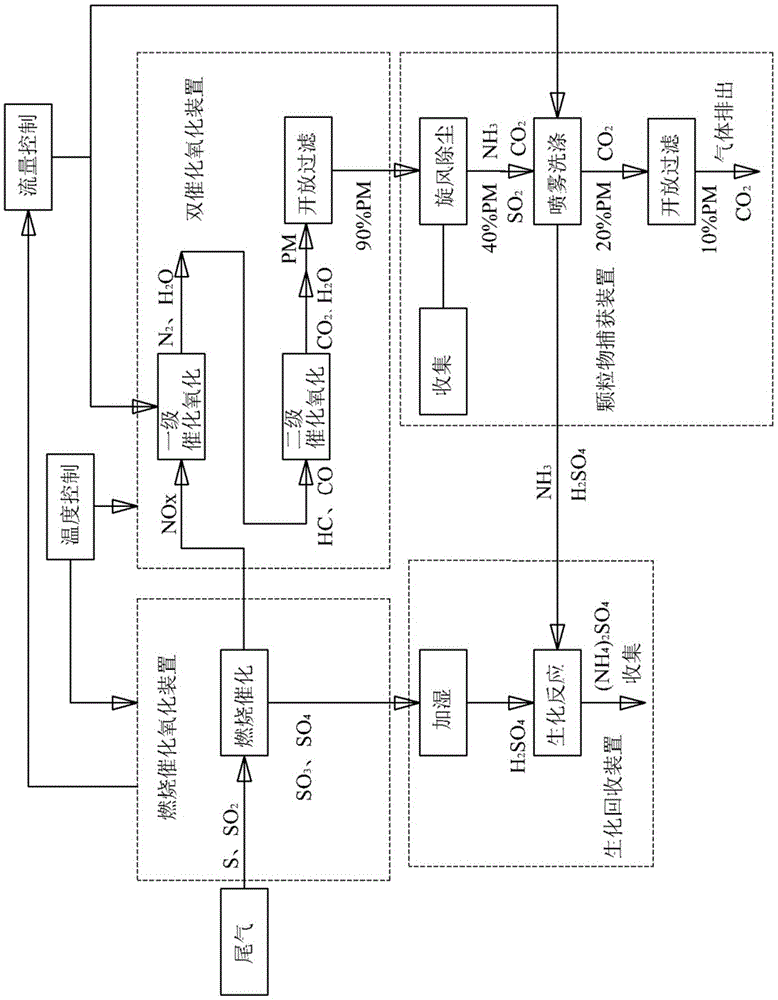

A comprehensive treatment and flue gas technology, applied in the direction of combined device, air quality improvement, combustion method, etc., can solve the problems of large area of equipment and separate operation, and achieve good removal effect, high removal efficiency, economic and environmental benefits Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

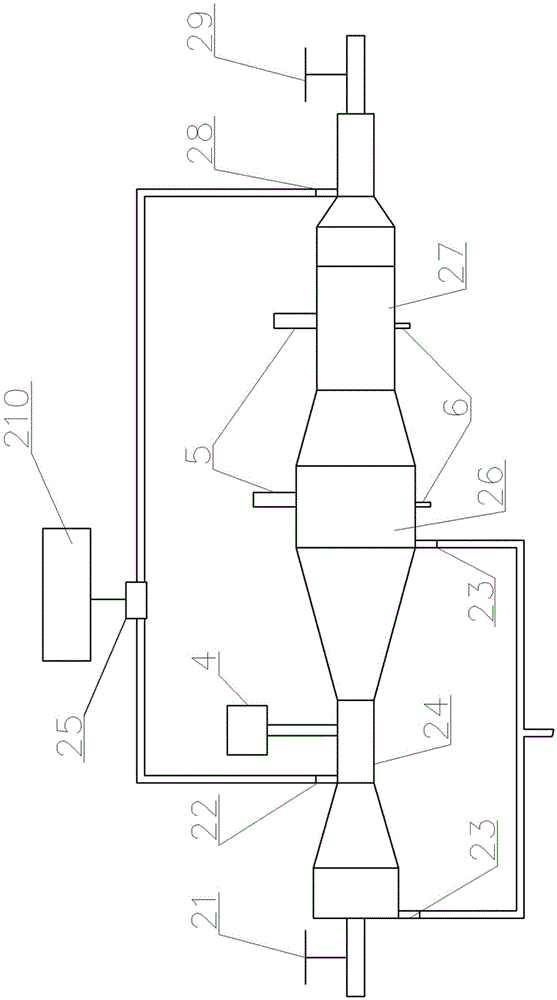

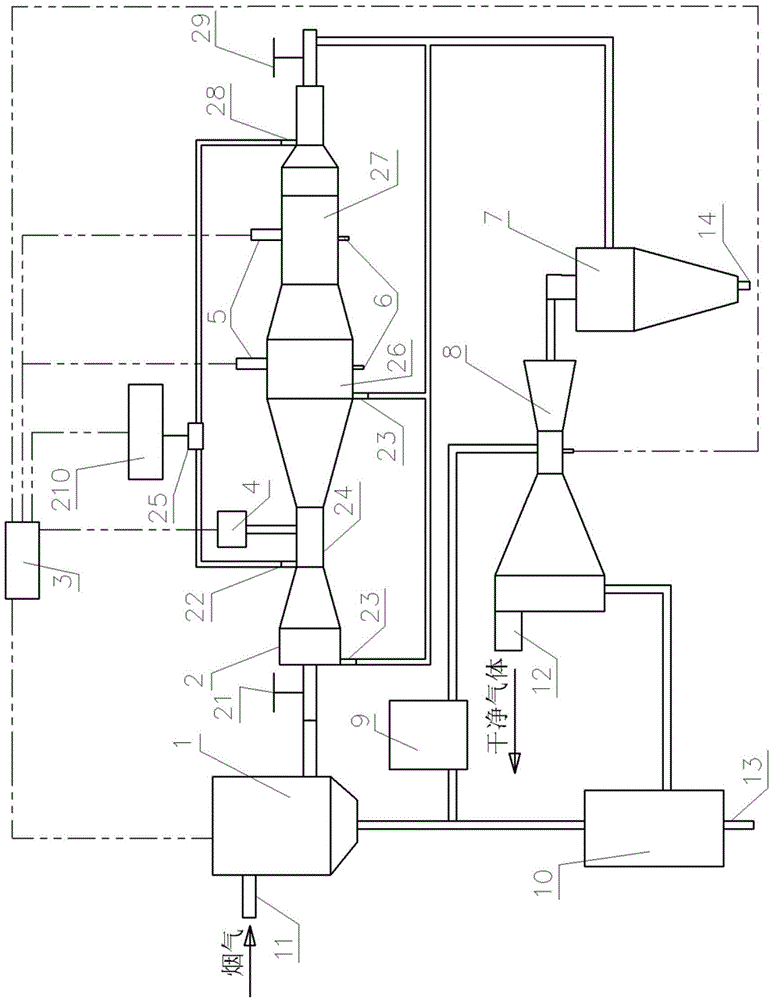

[0036] In the comprehensive flue gas treatment system of this embodiment, the secondary SCR catalytic oxidation device used is as figure 1 As shown, it includes a venturi tube 24 with a flue gas inlet, a primary catalytic reaction box 26 and a secondary catalytic converter 27 with a flue gas outlet. The flue gas inlet of the venturi tube 24 is provided with an inlet valve 21, two The flue gas outlet of the first-stage catalytic converter 27 is provided with an outlet valve 29;

[0037] The top of the Venturi tube 24 is provided with a reducing agent tank 4 for holding the SCR reducing agent, and the outlet at the bottom of the reducing agent tank 4 is connected with the feed port of the Venturi tube 24 for making the Venturi tube 24 The SCR reducing agent is inhaled and mixed with the flue gas by suction; a ceramic heater is arranged inside the diffusion end of the Venturi tube 24, and the surface of the ceramic heater is attached with an SCR catalyst; the diffusion of the Ven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com