Grain vibrating dampener

A water machine and grain technology, applied in grain processing, grain milling, application, etc., can solve the problems of uneven water distribution, low water permeability, easy mildew of grains, etc. The effect of saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will now be further described in conjunction with specific examples, and the following examples are intended to illustrate the present invention rather than further limit the present invention.

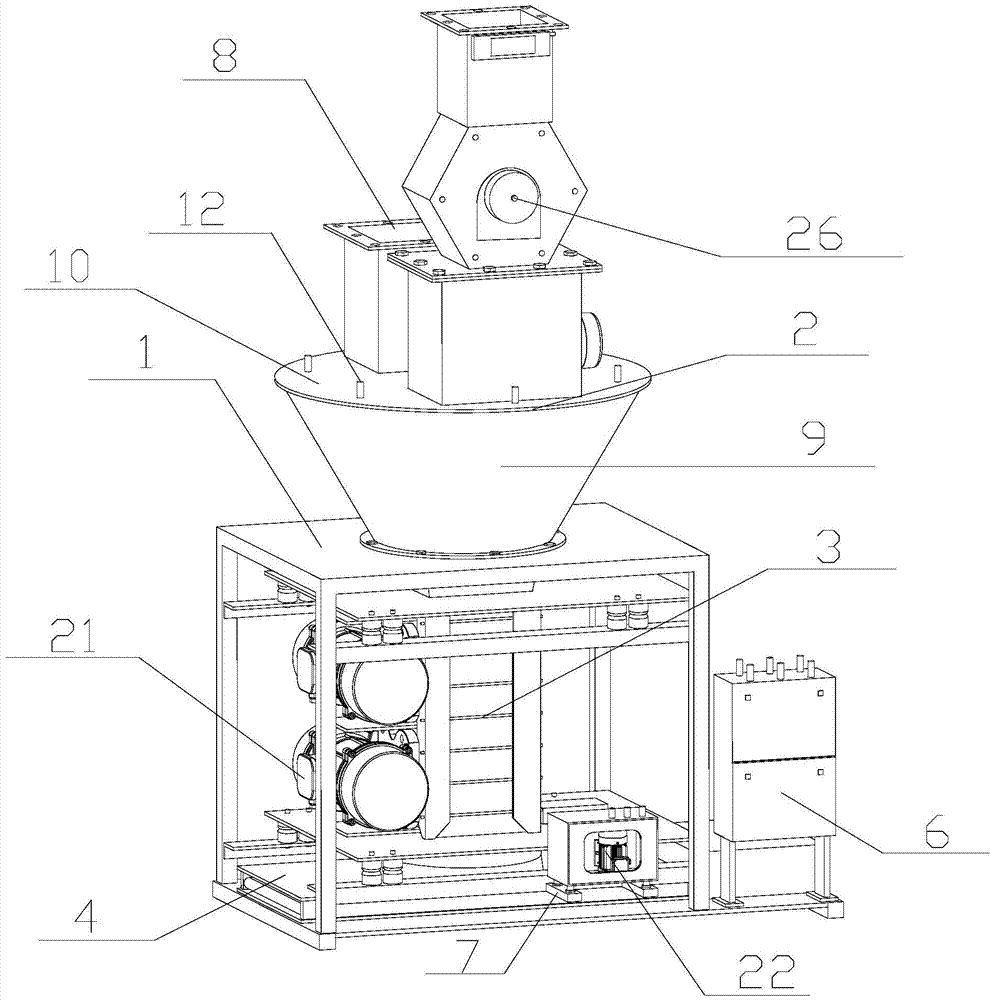

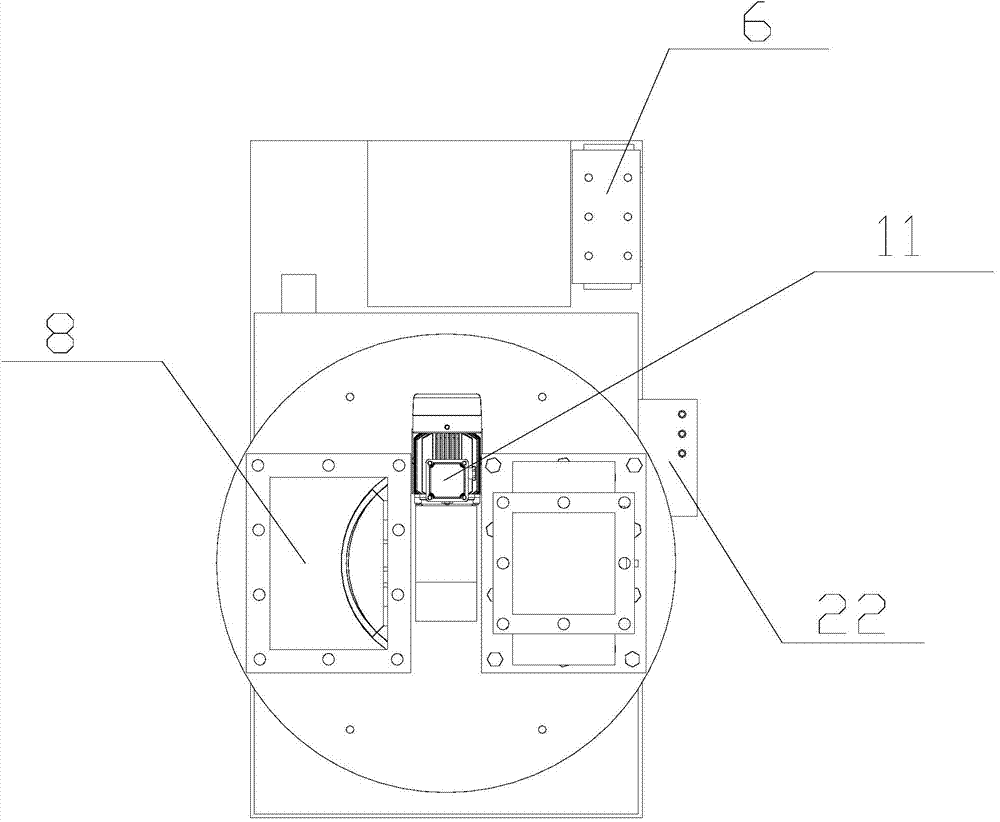

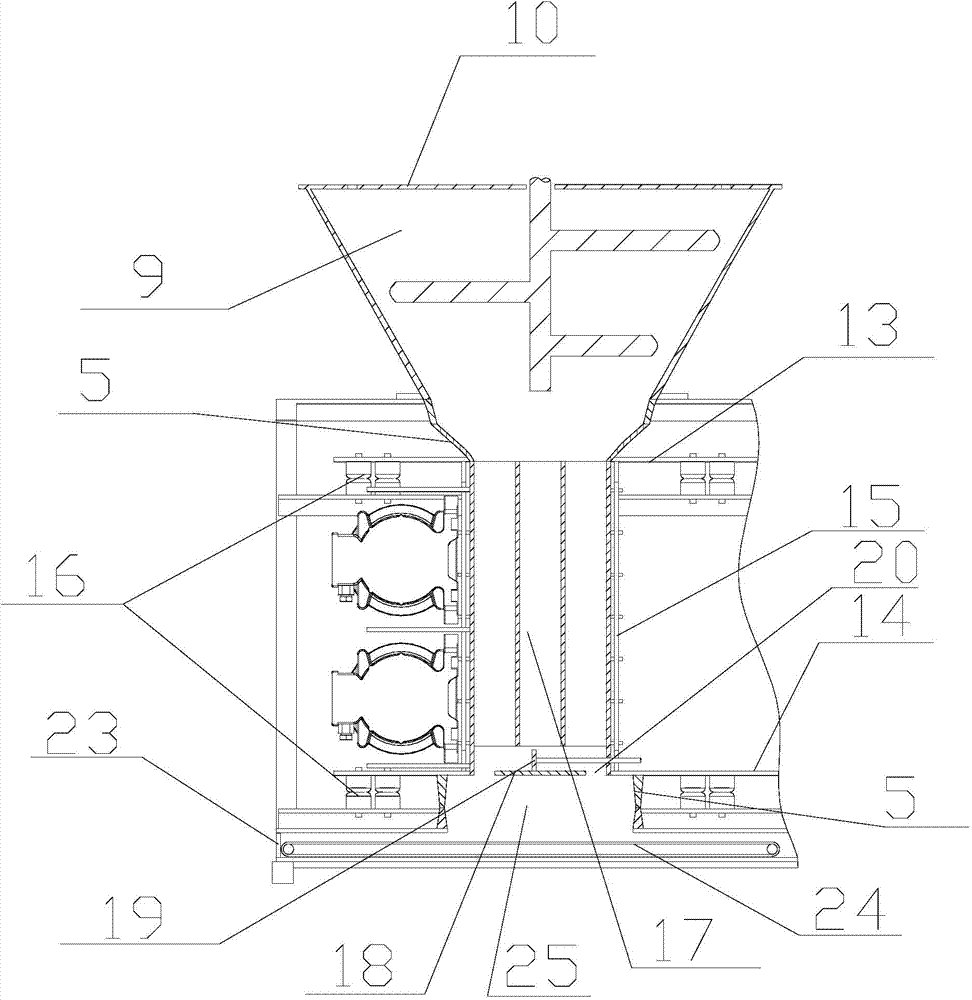

[0029] like Figure 1~3 As shown, a grain vibration watering machine, the vibration watering machine includes a bracket 1 and a water distribution system 6, the upper part of the bracket 1 is fixed with a feeding mechanism 2, and the bracket 1 is sequentially provided with a vibration chamber 3 and an outlet. The feeding mechanism 4, the vibration chamber 3 is located under the feeding mechanism 2, the discharging mechanism 4 is located at the bottom of the support 1, the feeding mechanism 2 and the vibration chamber 3, the vibration chamber 3 and the discharging mechanism 4 are connected by a soft connection pipe 5, and the water distribution The system 6 is connected to the feeding mechanism 2 through several water inlet pipes, and the vibrating watering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com