Special crusher

A technology of crusher and motor reducer, which is applied in the fields of food crushing equipment and pharmaceuticals. It can solve the problems that the agglomerated logistics containing moisture are not easy to break and affect the drying process, and achieve uniform and fine crushing of logistics, low operating costs and ideal results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

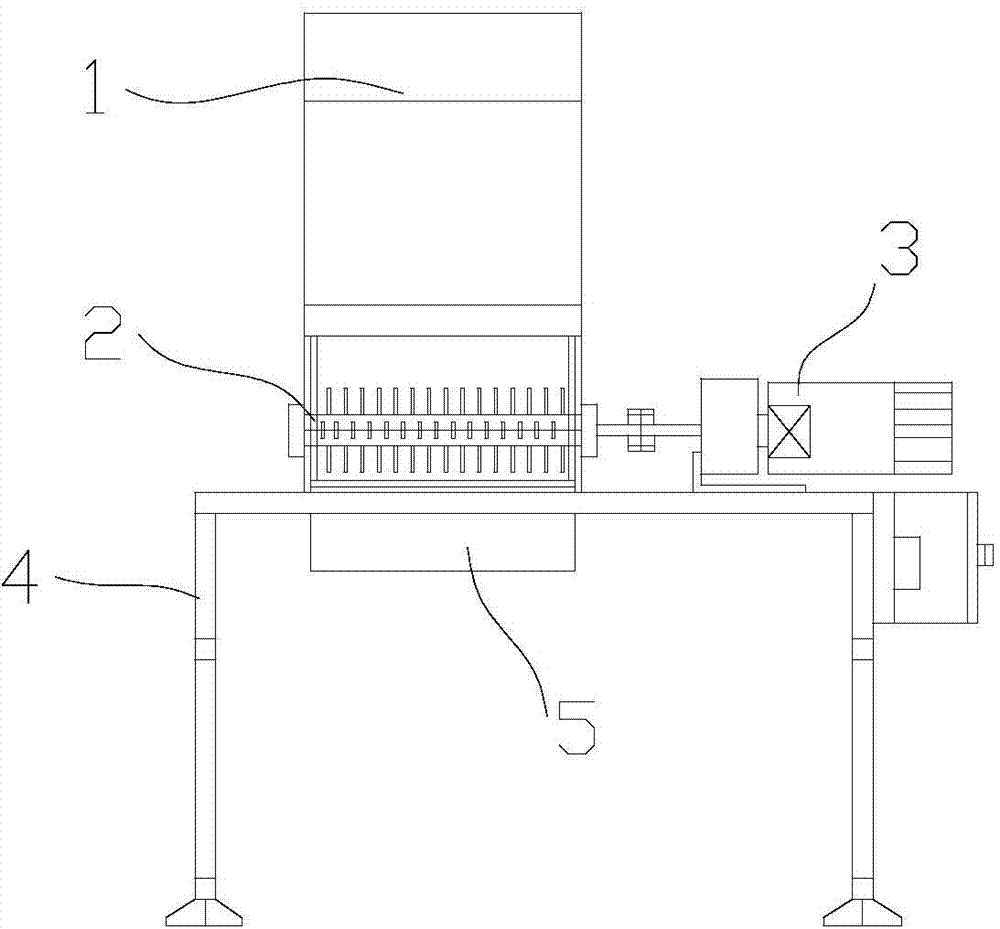

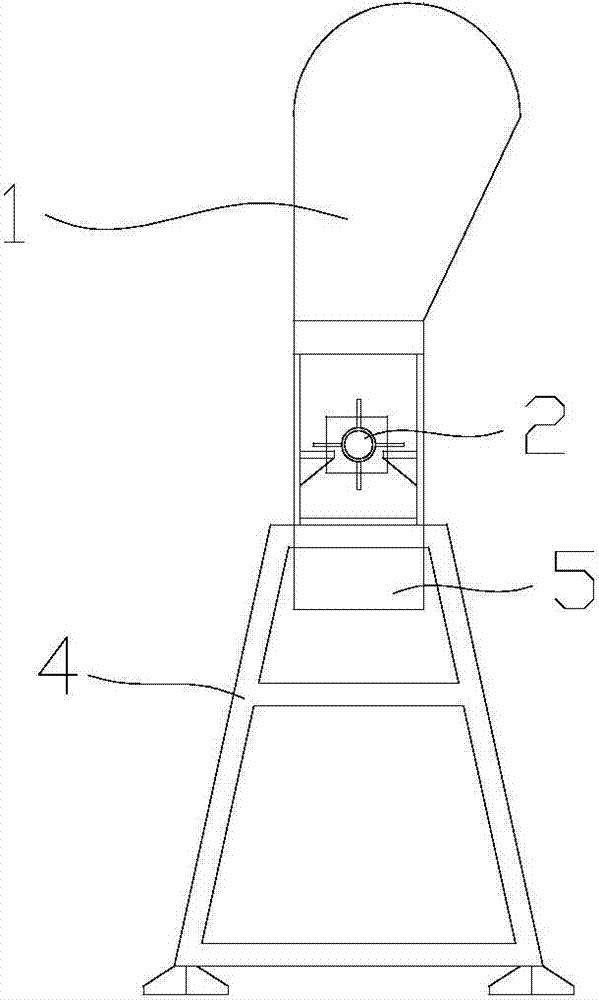

[0015] Such as figure 1 As shown, the special crusher includes a stirring blade 2 installed on the rotor for crushing wet materials. The rotor is linked with a motor reducer 3. The stirring blade 2 is arranged in a semi-enclosed space surrounded by a stainless steel cover 1. At the bottom, the front of the stainless steel cover 1 is provided with a feed inlet, and the bottom of the stirring blade 2 is provided with a discharge port 5 , and the stainless steel cover 1 , stirring blade 2 and motor reducer 3 are arranged on a horizontal support 4 .

[0016] The stirring blades 2 are evenly arranged on the surface of the rotor.

[0017] The size of the discharge port 5 is smaller than the opening size of the stainless steel tank car.

[0018] The feed inlet of the stainless steel cover 1 also includes a switchable baffle.

[0019] The embodiments of the present invention have been described in detail above, but the content described is only a preferred embodiment of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com