Method and device for lubricating and cooling the injection punch of a die-casting machine

A technology of injection punch, lubrication and cooling, which is applied in the field of casting, can solve the problems of affecting the air tightness of products, uncontrollable cooling, pulling, etc., and achieve the effect of reducing the production cost of enterprises, reducing the backflow of molten metal, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

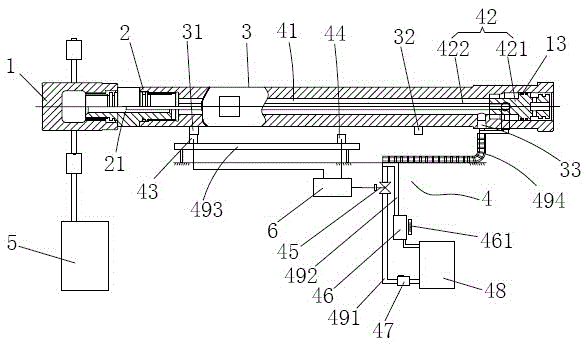

[0028] Such as Figure 1-5 As shown, a lubricating and cooling system for the injection punch of a die-casting machine in the present invention includes an injection punch 1, a connecting head 2, a injection rod 3, a cooling device 4, a lubricating device 5 and a PLC controller 6 on the die-casting machine, The injection punch 1 is fixedly connected with the injection rod 3 through the connection head 2 .

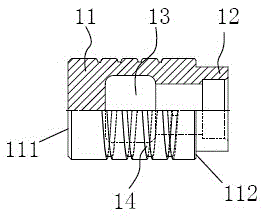

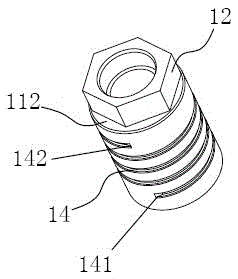

[0029] The above injection punch 1 includes a cylindrical punch body 11 and a connecting piece 12, a cooling cavity 13 is opened in the punch body 11, a spiral oil suction groove 14 is opened on the outer peripheral surface of the punch body 11, and the spiral oil suction The groove width of the groove 14 is 2.5-3.5mm, the groove depth is 1.5-2.5mm, and the pitch is 12mm; The vertical distance between the rear end surface 112 of the punch body is 12mm; the above-mentioned connecting head 2 is provided with an axial through hole 21, and the connecting head 2 and the connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com