Fully-automatic tapping machine

A tapping machine and fully automatic technology, applied in the field of tapping machines, can solve the problems of unfavorable production efficiency and cost saving, waste of processing time, loss of machines, etc., so as to save labor and production costs, improve production efficiency, and reduce the number of machines wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described below in conjunction with accompanying drawing.

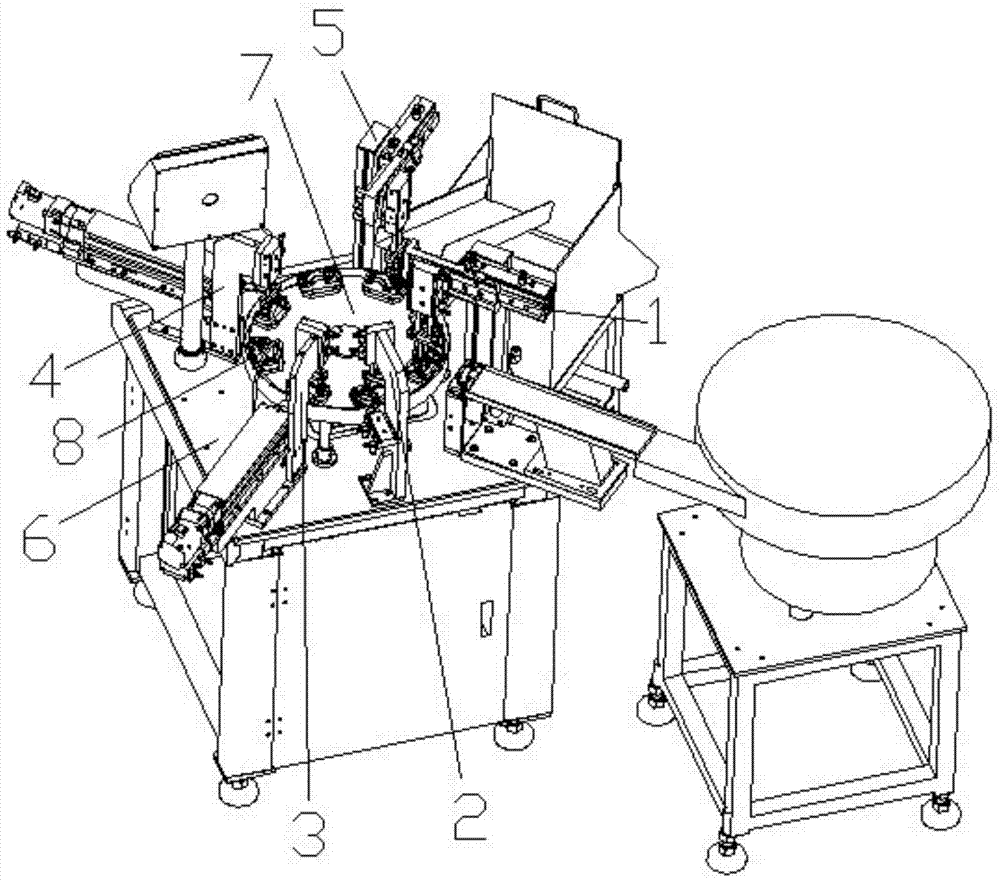

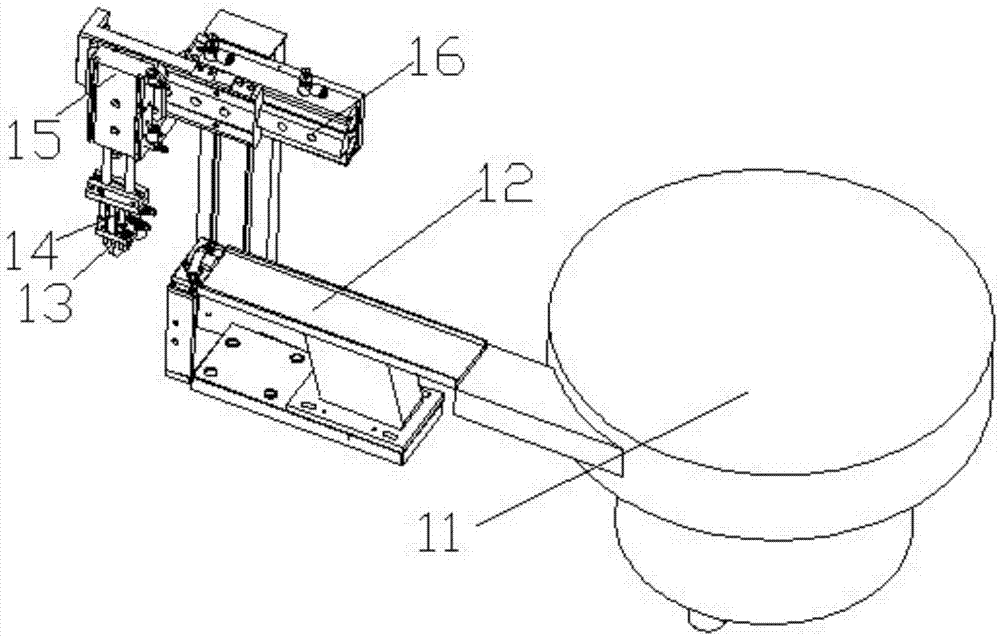

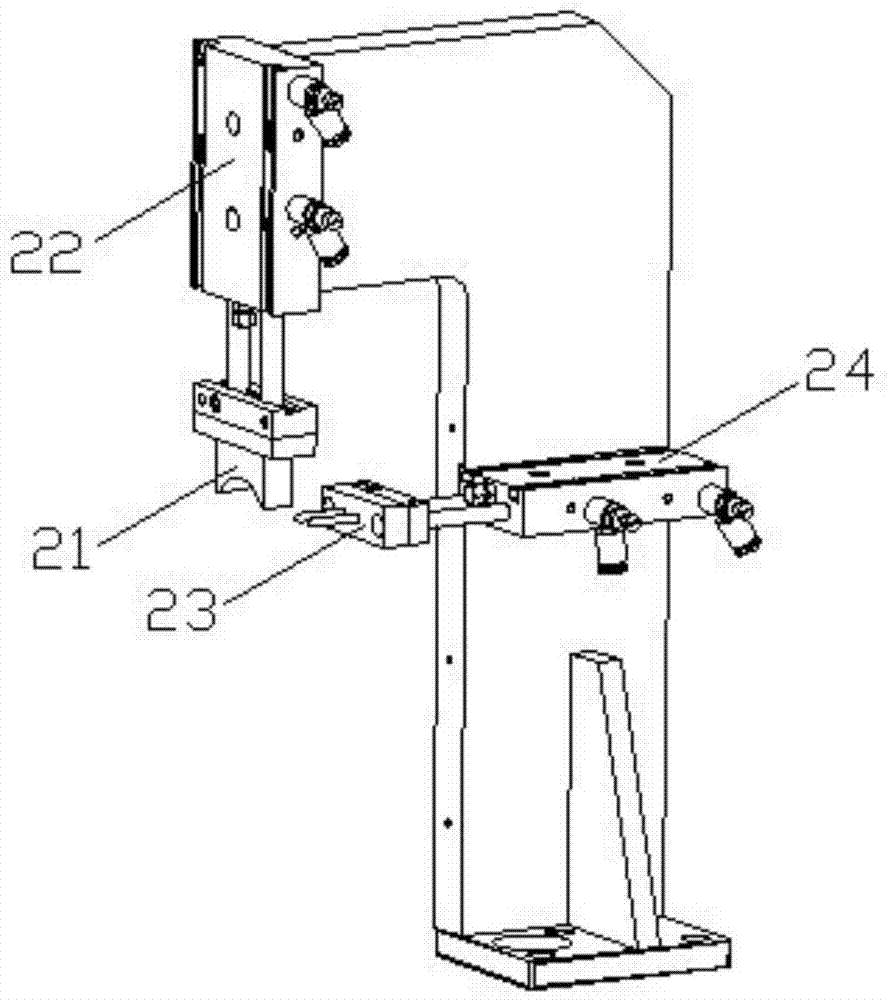

[0019] as attached figure 1 , 2 Shown is a kind of automatic tapping machine described in the present invention, comprises machine table 6 and indexing plate 7; Said indexing plate 7 is arranged on the center of machine table 6; Said indexing plate 7 is provided with mold 8 , the indexing plate 7 is an eight-station indexing plate, and the mold 8 is correspondingly provided with eight; the periphery of the indexing plate 7 is sequentially provided with a feeding device 1, a hole position detection device 2, and a first tapping device 3 , The second tapping device 4 and the receiving device 5. The feeding device 1 clamps the parts to be tapped into the mold 8 on the indexing plate 7, and the indexing plate 7 rotates to transfer the parts on the mold 8 to the station of the hole position detection device 2, and the hole position The detection device 2 inspects the size and position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com