Air-cooled welding torches for automatic welding lines

An automatic welding and production line technology, applied in the direction of electrode clip cooling, electrode characteristics, electrode support device, etc., can solve the problems of blockage of cooling water circulation, poor water cooling effect, inconvenient production, etc., to improve production efficiency, convenient operation and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

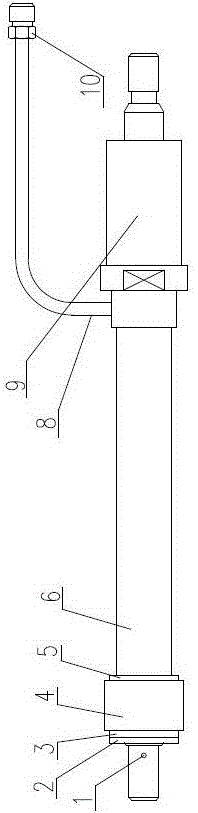

[0018] An air-cooled welding gun used in an automatic welding production line, which consists of: a gun body 6, the threaded sleeve 4 at the front of the gun body is fixed by a retaining ring 2, an insulating retaining ring 3 and an insulating sleeve A, part number: 5 On the gun body, the tail of the gun body is equipped with a connecting pipe 8 and an insulating sleeve B, part number: 9. The surface of the gun body and the connecting pipe is wrapped with insulating tape, and the connecting pipe A joint 10 is installed at the tail.

Embodiment 2

[0020] According to the air-cooled welding gun used in the automatic welding production line described in embodiment 1, the tail and front end of the gun body are respectively provided with an air inlet and an exhaust port, and a guide wire hole for the welding wire is opened in the middle; There is a rectangular groove on the outside of the cover, which is connected with a special nozzle; the front end of the gun body is provided with three exhaust holes 1 surrounding the gun body, and the position of the exhaust holes is at the front end of the insulating retaining ring.

Embodiment 3

[0022] According to the air-cooled welding gun used in the automatic welding production line described in embodiment 1, the guide wire nozzle, the special nozzle and the gas pipe for introducing carbon dioxide are respectively installed on the gun body, the threaded sleeve and the joint, and the clamping device on the automatic welding production line Step up and adjust the angle on the insulating sleeve B for automatic welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com