Folding arm frame, fiber reinforced resin matrix composite material arm section and manufacturing method thereof

A technology of fiber-reinforced resin and composite materials, which is applied in the field of manufacturing of folding booms and fiber-reinforced resin-based composite material boom sections, which can solve problems such as increased production costs, low stiffness, and poor impact resistance of folding booms, and achieve savings Production cost, effect of improved impact resistance and stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0033] In the present invention, in the case of no contrary description, the used orientation words such as "up, down, left and right" usually refer to the up, down, left and right shown in the accompanying drawings; "inside and outside" Refers to the inside and outside of the outline of each part itself.

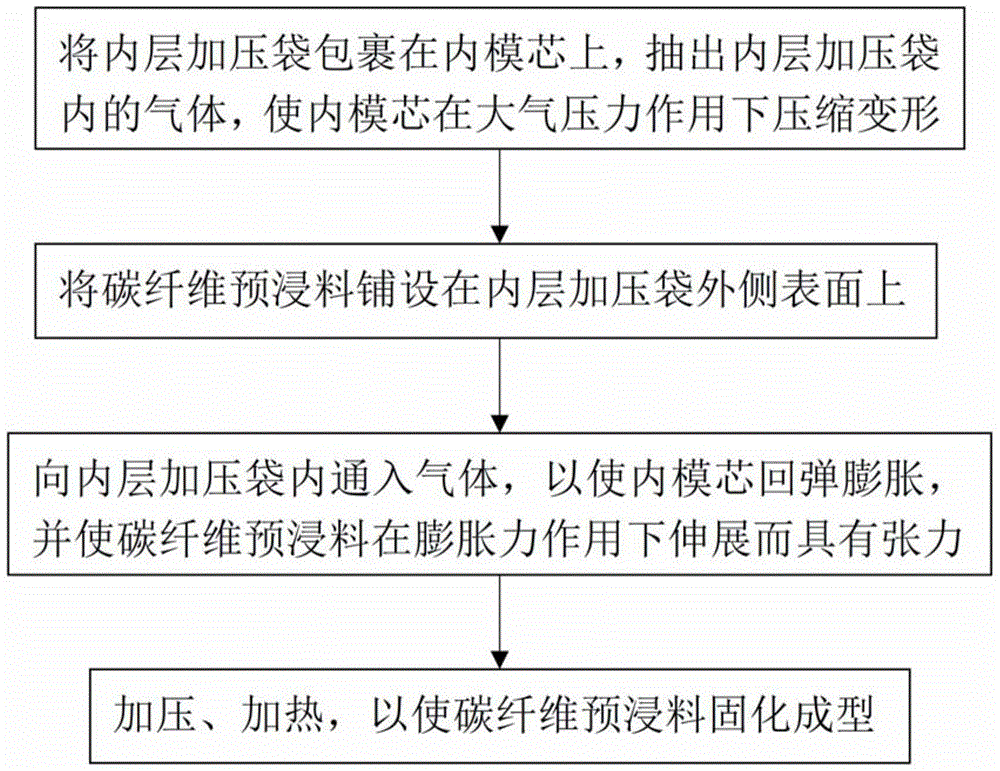

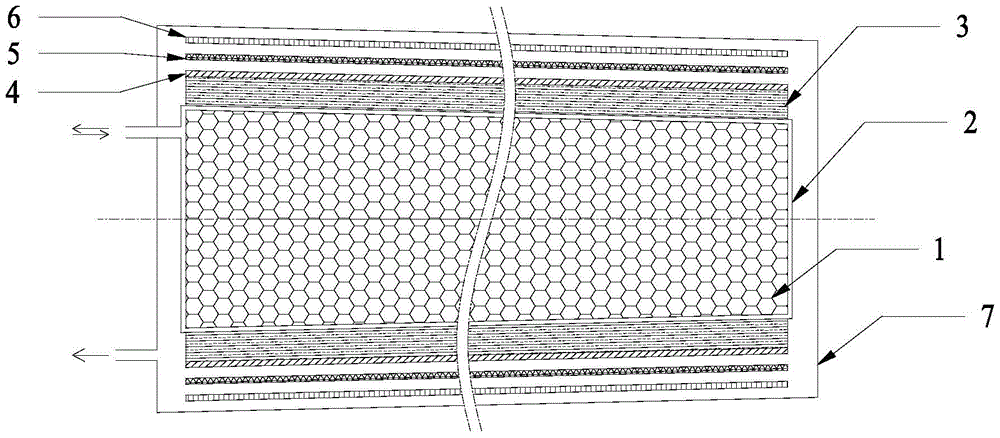

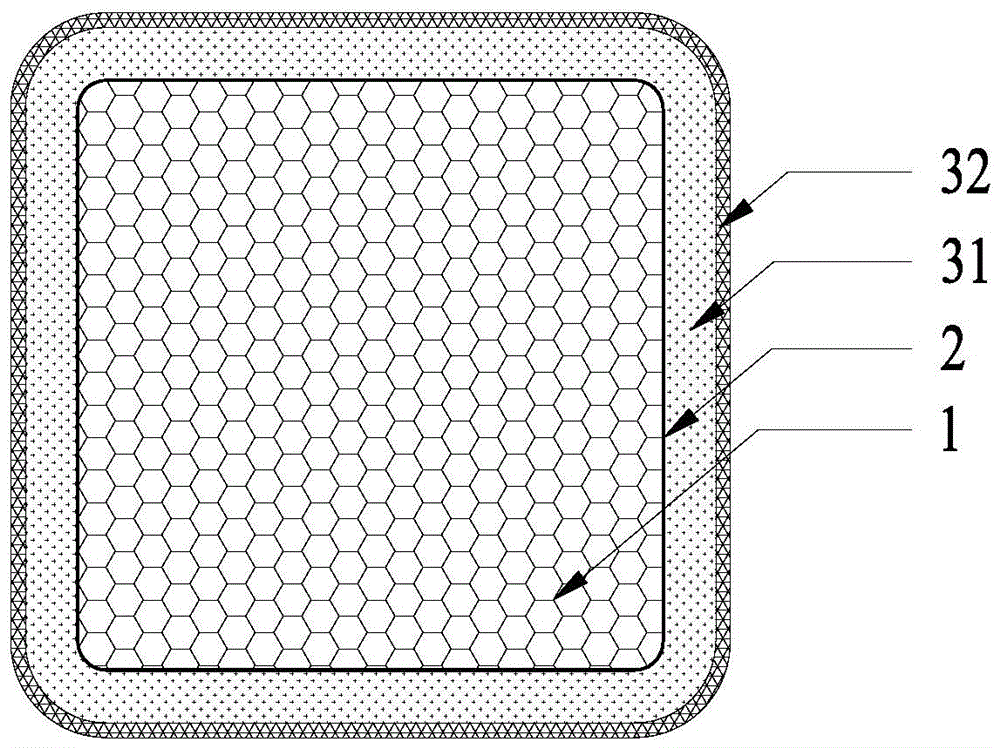

[0034] refer to Figure 1 to Figure 3 According to a specific embodiment of the present invention, a method for manufacturing a fiber-reinforced resin-based composite material arm section includes the following steps: first, wrapping the inner layer pressurized bag 2 on the inner mold core 1, and pulling out the inner layer pressurized bag 2 Press the gas i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com