Fixture and preparation method for staggered-type large-scale preparation of graphene

A large-scale preparation and graphene technology, which is applied in the jig and preparation field for the staggered large-scale preparation of graphene, can solve the problems such as the easy deformation of metal catalysts, the limitation of the number of graphene, and the reduction of the growth quality of graphene products. Quantity, easy operation, and the effect of avoiding sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

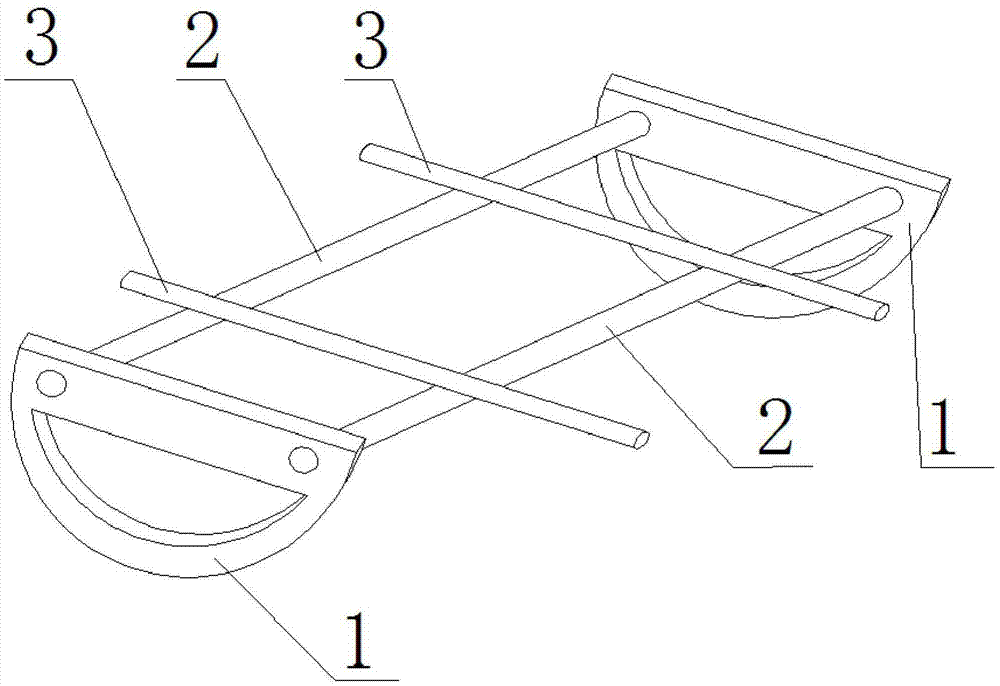

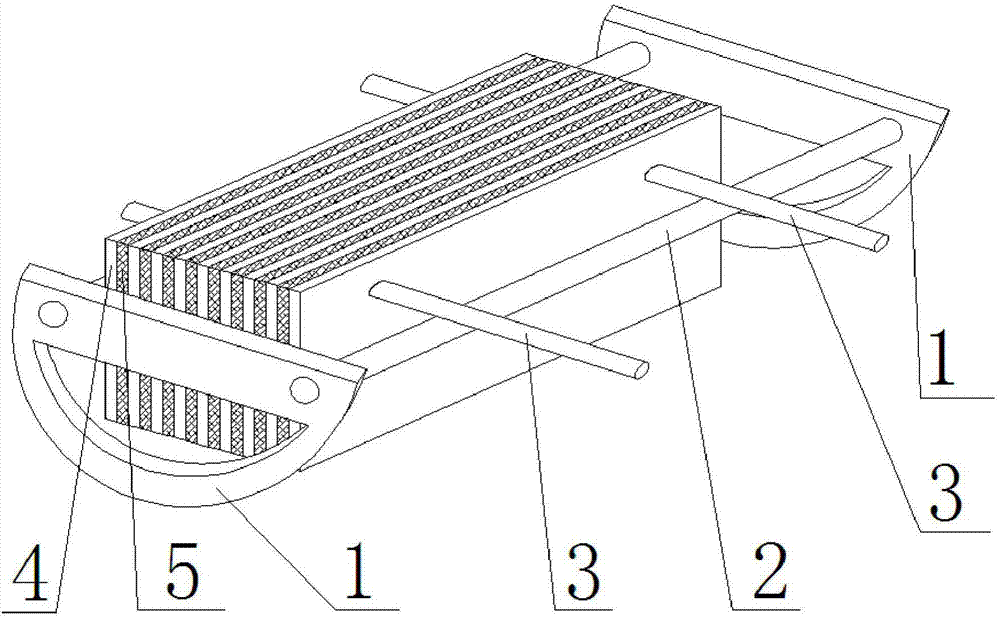

[0027] Such as figure 1 As shown, the fixture of this embodiment includes two vertically arranged support frames 1, and the two support frames 1 are fixedly connected by two parallel support rods 2, and the two ends of the two support rods 2 are respectively connected to the two The top of each support frame 1 is fixed, and the two support rods 2 are on the same horizontal plane and there is a gap between the two support rods 2, and two support rods 3 are placed on the two support rods 2. The material of the support frame 1 , the support rod 2 and the support rod 3 is a high-temperature-resistant hard material or an ordinary hard material with a high-temperature-resistant layer spin-coated on the surface. The vertical section of the support frame 1 is square or trapezoidal or semicircular, and the support rod 3 is a cylindrical rod with a diameter of 1-10 mm.

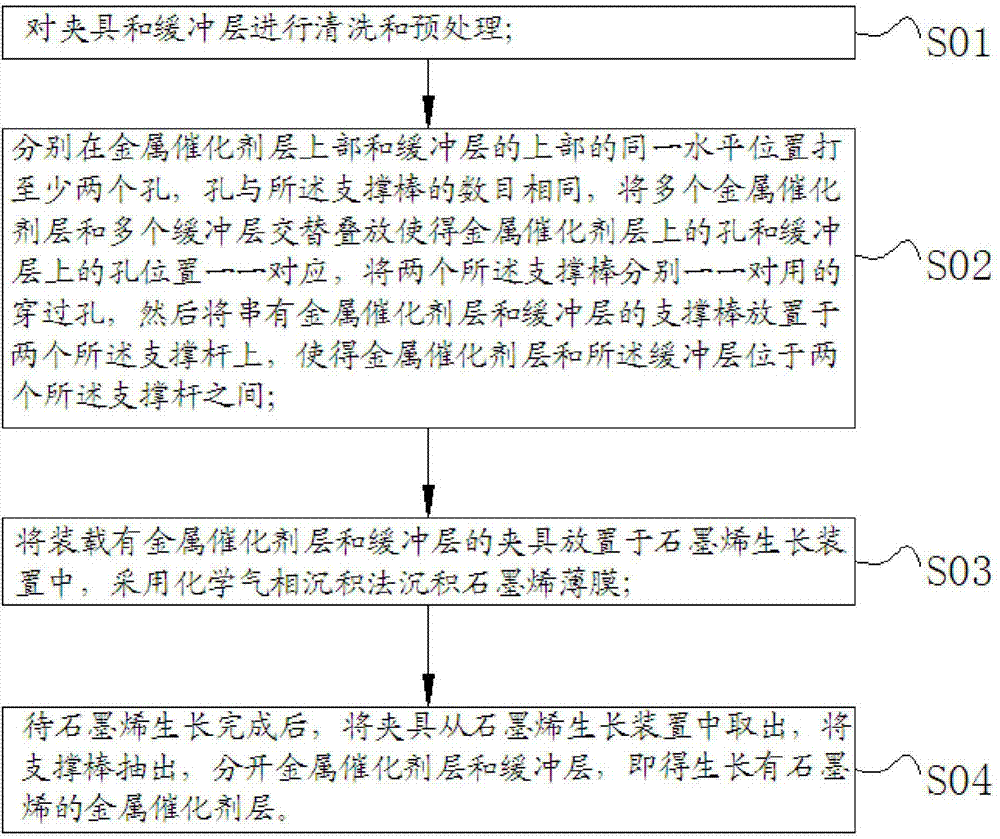

[0028] Such as image 3 Clean and pre-treat the jig and buffer layer as shown in Fig. 1: Clean the jig and buffer l...

Embodiment 2

[0033] Such as figure 1 As shown, the fixture of this embodiment includes two vertically arranged support frames 1, and the two support frames 1 are fixedly connected by two parallel support rods 2, and the two ends of the two support rods 2 are respectively connected to the two The top of each support frame 1 is fixed, and the two support rods 2 are on the same horizontal plane and there is a gap between the two support rods 2, and two support rods 3 are placed on the two support rods 2. The material of the support frame 1 , the support rod 2 and the support rod 3 is a high-temperature-resistant hard material or an ordinary hard material with a high-temperature-resistant layer spin-coated on the surface. The vertical section of the support frame 1 is square or trapezoidal or semicircular, and the support rod 3 is a cylindrical rod with a diameter of 1-10 mm.

[0034] Cleaning and pretreatment of the fixture and polytetrafluoroethylene high-temperature cloth: ultrasonically c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com