Apparatus and method for producing acetic acid through alkaline fermentation of residual sludge which is reinforced by pretreatment of strong base

A technology of excess sludge and alkali pretreatment, which is applied in the directions of biomass pretreatment, biochemical cleaning devices, biochemical equipment and methods, etc., can solve the problems of low acetic acid production and achieve the effect of increasing acetic acid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

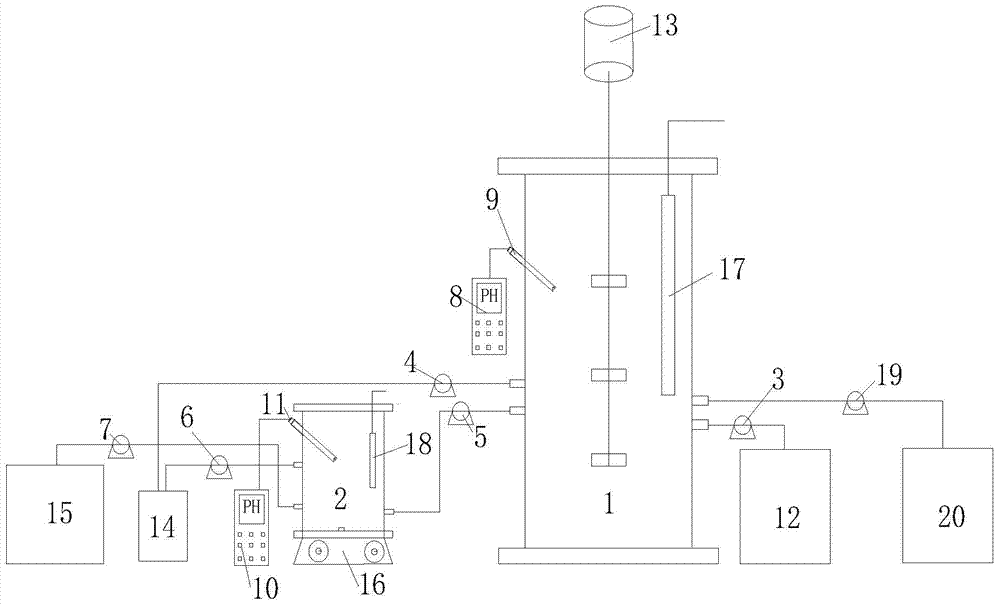

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described: as figure 1 As shown, a strong alkali pretreatment device and method for strengthening the alkaline fermentation of excess sludge to produce acetic acid is characterized in that it is equipped with a fermentation SBR1, a pretreatment SBR2, a fermentation sludge pump 3, a fermentation alkali pump 4, and a pretreatment discharge pump. Sludge pump 5, pretreatment alkali pump 6, pretreatment mud inlet pump 7, fermentation pH meter 8, fermentation pH probe 9, pretreatment pH meter 10, pretreatment pH probe 11, fermentation mud discharge box 12, fermentation agitator 13. NaOH medicine box 14, excess sludge tank 15, magnetic stirrer 16, fermentation heating rod 17, pretreatment heating rod 18, fermentation acid pump 19 and HCl medicine box 20. The bottom of the pretreatment SBR2 is provided with a magnetic stirrer 16, and the pretreatment SBR2 is provided with 5 valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com