Storage battery stand column dismounting vehicle

A battery and column technology, which is applied in the direction of lifting devices, pillars/brackets, mining equipment, etc., can solve the problems of high labor intensity, low work efficiency, and easily damaged columns, so as to improve disassembly and assembly efficiency, save maintenance costs, and improve The effect of the work environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

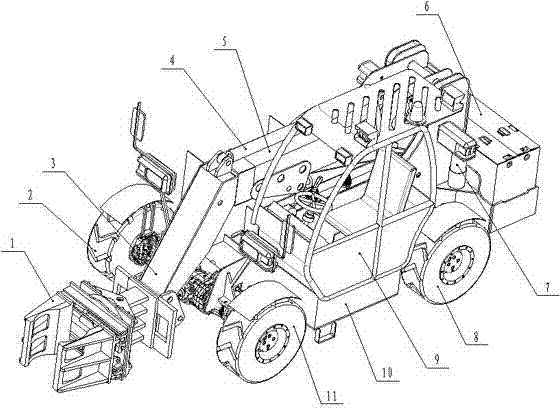

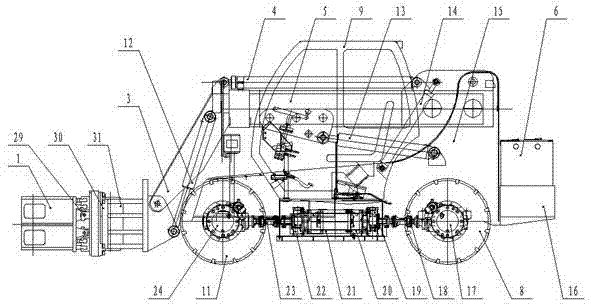

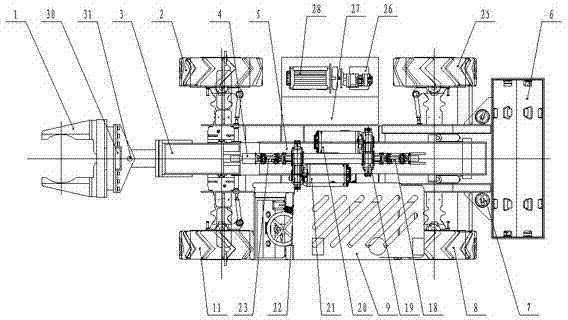

[0034] figure 1 , 2 . As shown in 3, it is the structural diagram of the battery post disassembly and assembly vehicle. The position and connection relationship of each part must be correct and the installation should be firm.

[0035] The front part is the clamping device: including clamping mechanism 1, clamping cylinder 29, rotating mechanism 30 and swinging mechanism 31, the rear part of the manipulator is connected with the leveling cylinder 12 and the telescopic arm 3 through the pin shaft, and the telescopic arm 3 is connected through the telescopic cylinder 4 is connected with the telescopic arm tube 5, the telescopic arm tube 5 is connected with the chassis 15 through the pin shaft and the lifting cylinder 13, the battery bracket 16 is connected with the chassis 15 through bolts, and the battery 6 is connected with the battery bracket 16 in a plug-in manner.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com