Deceleration and speed change integrated face gear pair and processing method thereof

A face gear, deceleration and speed change technology, which is applied in the field of non-circular gear transmission pairs and processing, can solve the problems of inability to realize deceleration and speed reduction integrated transmission, and can not realize deceleration and speed change transmission, so as to improve transmission efficiency and precision, shorten transmission chain, Reduce the effect of transmission parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with accompanying drawing:

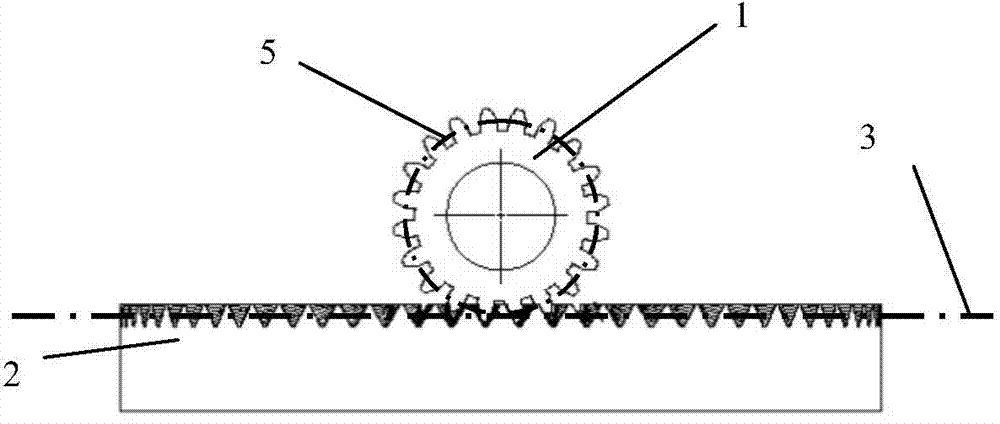

[0046] figure 1 It is the front view of the small cylindrical gear 1 and the face gear 2 after assembly, the small cylindrical gear and the face gear rotate around a fixed axis, and the rotation axes of the two are orthogonal. The cylindrical surface where the index circle of the small cylindrical gear is located is the pitch cylindrical surface 5 of the small cylindrical gear, the pitch surface 3 of the face gear is a plane, and the pitch cylindrical surface is tangent to the pitch surface.

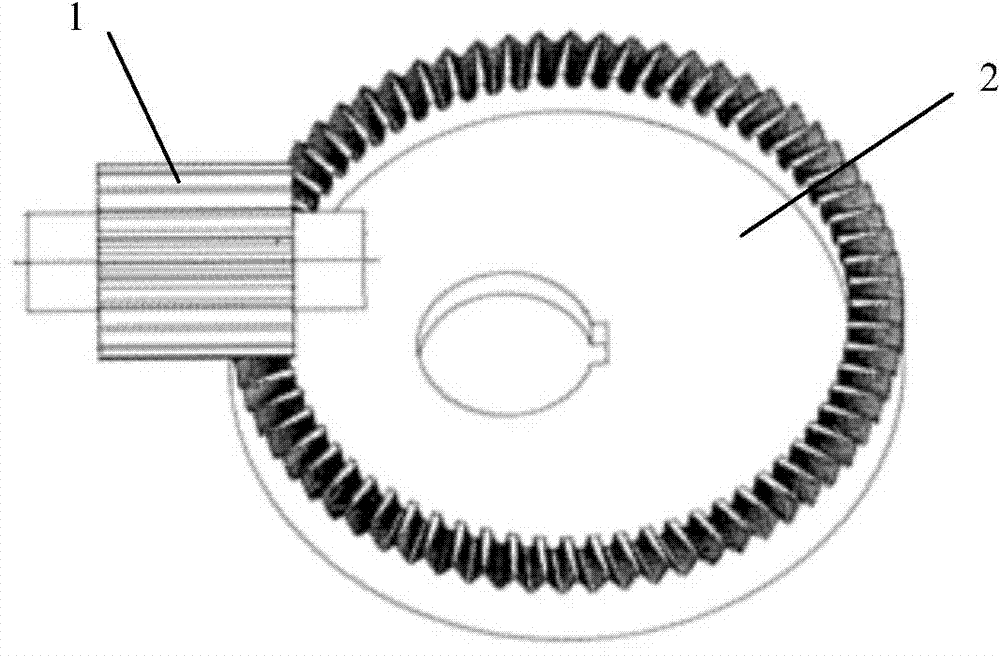

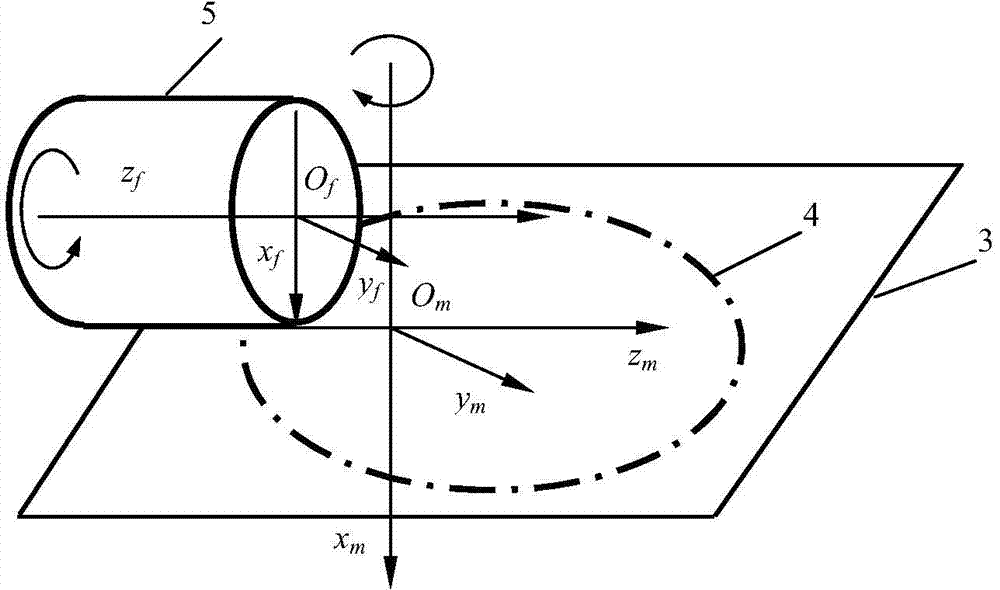

[0047] figure 2 is the assembly diagram of the small cylindrical gear and the face gear, and the pitch curve 4 of the face gear is a plane curve on the pitch surface, such as image 3 shown. When the small cylindrical gear and the face gear rotate relatively, the pitch cylindrical surface and the pitch curve keep pure rolling, then the transmission ratio i realized by the small cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com