Biomass solid fuel ash high-temperature melting monitoring device based on capacitance measurement

A technology of high-temperature melting and solid fuel, applied in the direction of material capacitance, etc., can solve the problems of difficult to monitor accurately and take preventive measures in time, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

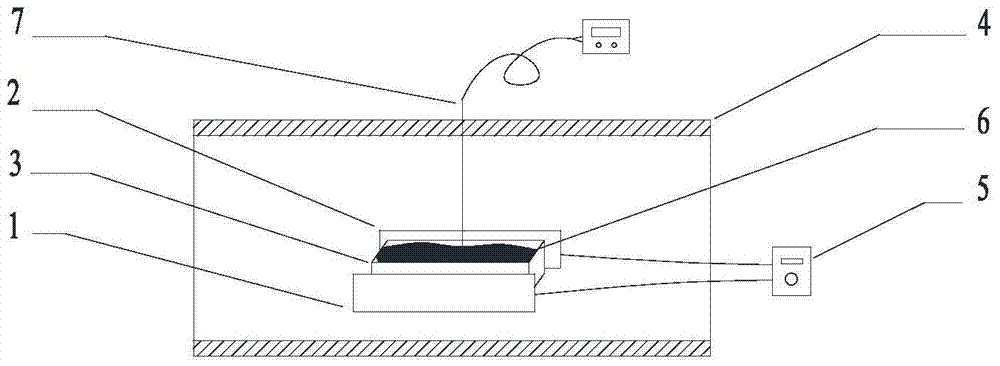

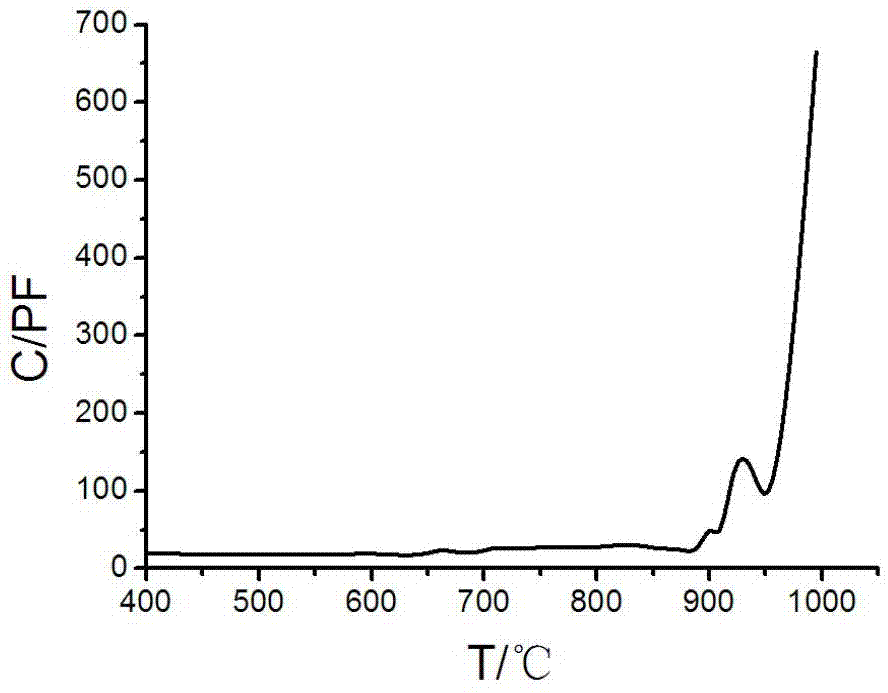

[0028] figure 1 Shown is a schematic diagram of the structure of the ash melting capacitance testing experimental device, which is mainly composed of a pair of capacitor plates 1 and 2, an ash melting container 3 made of corundum, and an electric heating jacket 4. The capacitor plates 1 and 2 are connected to a capacitance tester 5. For the convenience of measurement and the improvement of accuracy, the change of capacitance before and after melting is designed to be greater than 10PF. Refer to the calculation method of parallel plate capacitance, and the reference value of dielectric constant is 2-10. Load the biomass ash sample 6 (i.e. ash) in the ash melting container 3 and put the ash melting container 3 into the electric heating jacket 4, control the temperature rise through the electric heating program to make the temperature in the ash melting container 3 reach the melting point of the ash sample , the temperature of the ash melting container 3 is measured by a thermoco...

Embodiment 2

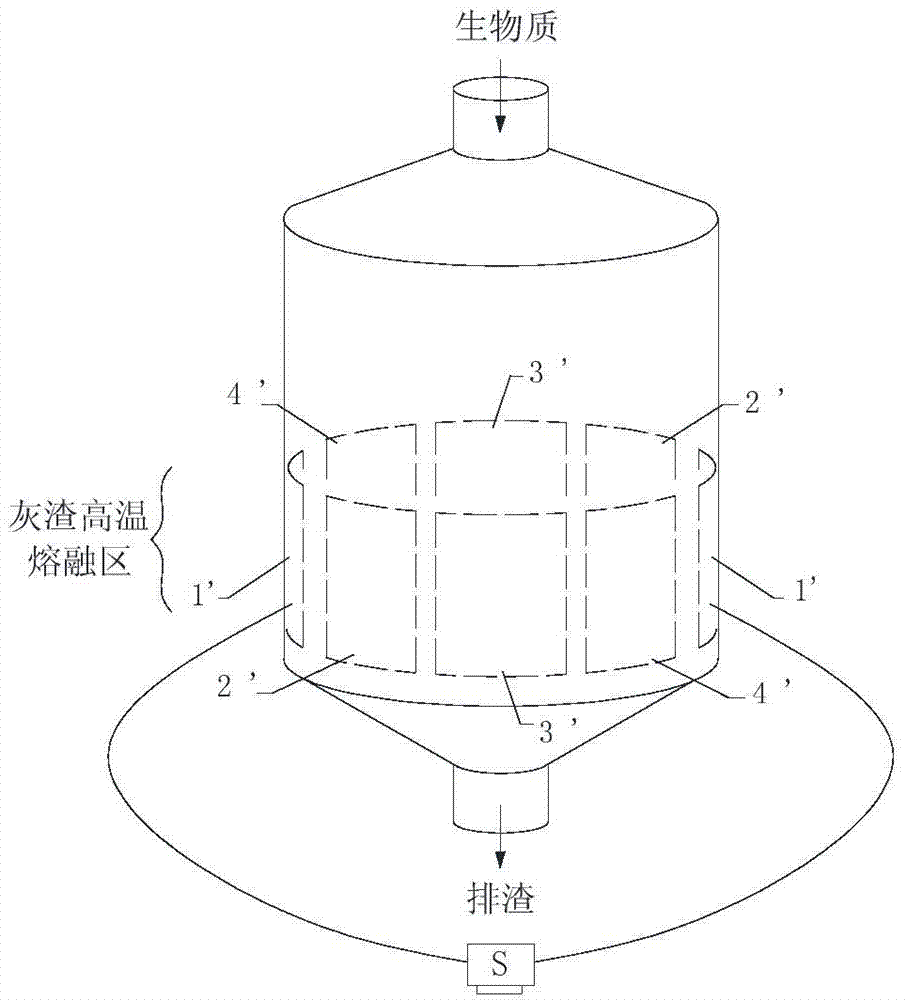

[0031] image 3 It is a structural diagram of a real-time capacitance monitoring device for biomass ash melting in the process of biomass gasification and combustion, taking the fixed-bed gasifier, which is widely used in industry, as an example. The biomass raw material enters the fixed-bed gasifier from the top of the furnace, and the carbon-containing ash produced after the gasification reaction is concentrated at the bottom of the furnace, and the air entering from the bottom of the furnace undergoes an oxidation reaction with carbon to release heat, forming a high-temperature melting zone at the bottom of the furnace. Due to the uneven temperature distribution of the fixed bed, even if the overall temperature is controlled below the ash melting point of the biomass, the local temperature is still easy to reach and exceed the ash melting point, causing local ash melting and sintering. Measures such as heating, the molten slag can grow, and the melting area is further expan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com