Preparation method and product of nano-coated earphone wire

An earphone cable and nanotechnology, applied in the field of preparation of nano-coated earphone cables, can solve the problems of no relevant reports, poor surface feel, easy to be polluted, etc., and achieve the effect of reasonable process, low cost and good surface feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

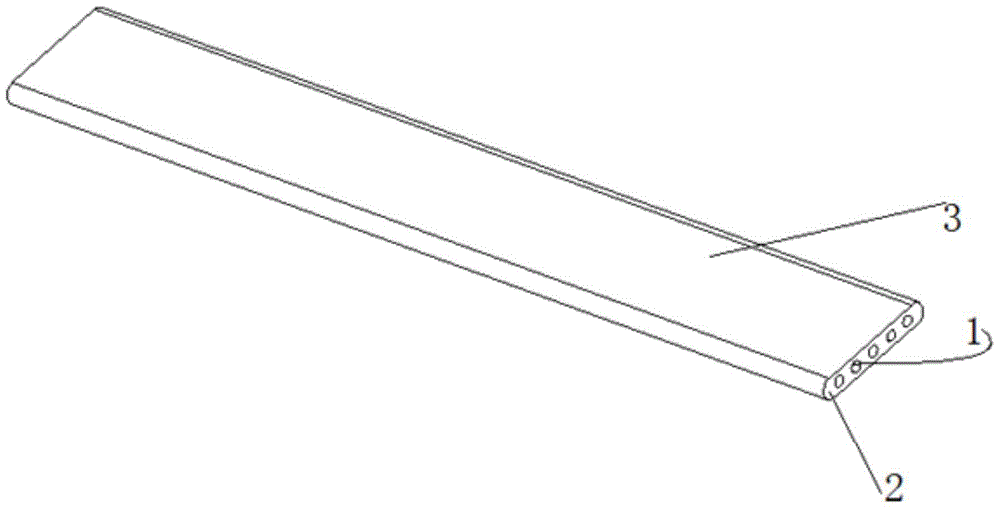

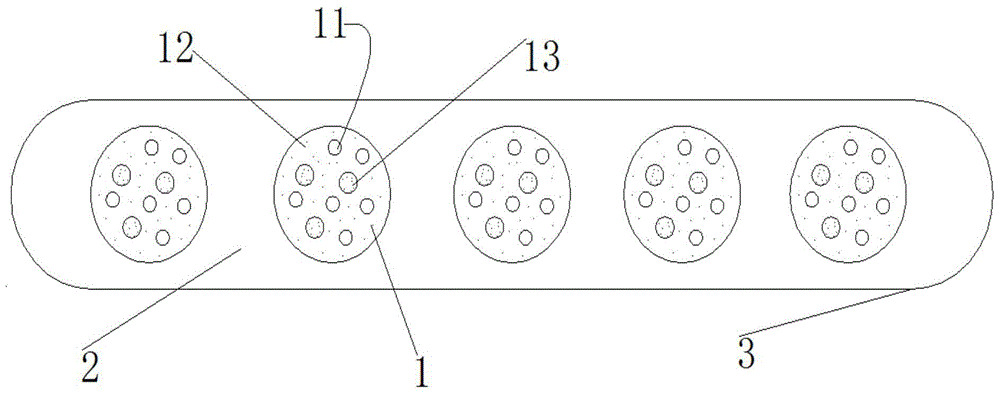

[0033] see Figure 1-2 , the preparation method of a kind of nano-coating earphone wire provided by the present invention, it comprises the steps:

[0034] (1) Preparation of a single wire: After the wire and the yarn are interspersed and spirally intertwined together, they are twisted together with the fiber bundle to make a single wire;

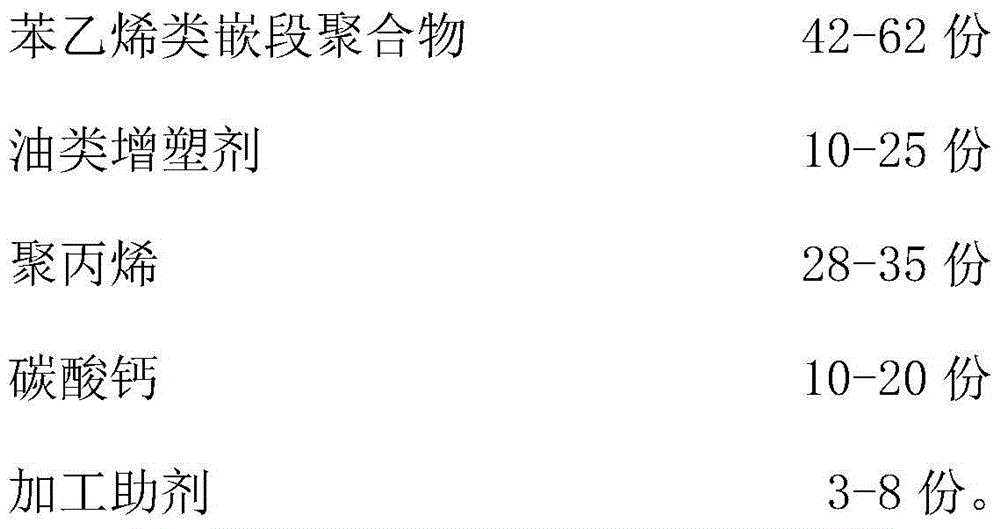

[0035] (2) Preparation of insulating jacket: weigh according to the set ratio and pour the raw materials of the insulating jacket into the reaction kettle, mix and extrude after high-speed stirring, and arrange several strands of the single wires described in step (1) in parallel , making the outside of the single wire extruded and plasticized to form an insulating outer coating layer;

[0036] (3) Preparation of nano-coating layer: hang the earphone wire prepared in step (2) vertically on the baking rack, then place it in the baking oven, and introduce the powdery parylene after gasification And fill the entire baking furnace, the gas is...

Embodiment 2

[0050]The preparation method of the nano-coated earphone cable and its products provided in this embodiment are basically the same as in Example 1, except that the preparation method of the nano-coated earphone cable specifically includes the following steps:

[0051] (1) Preparation of a single wire: After the wire and the yarn are interspersed and spirally intertwined together, they are twisted together with the fiber bundle to make a single wire;

[0052] (2) Preparation of insulating jacket: weigh according to the set ratio and pour the raw materials of the insulating jacket into the reaction kettle, mix and extrude after high-speed stirring, and arrange several strands of the single wires described in step (1) in parallel , making the outside of the single wire extruded and plasticized to form an insulating outer coating layer;

[0053] (3) Preparation of nano-coating layer: hang the earphone wire prepared in step (2) vertically on the baking rack, then place it in the ba...

Embodiment 3

[0062] The preparation method of the nano-coated earphone cable and its products provided in this embodiment are basically the same as those in Examples 1 and 2, except that the preparation method of the nano-coated earphone cable specifically includes the following steps:

[0063] (1) Preparation of a single wire: After the wire and the yarn are interspersed and spirally intertwined together, they are twisted together with the fiber bundle to make a single wire;

[0064] (2) Preparation of insulating jacket: weigh according to the set ratio and pour the raw materials of the insulating jacket into the reaction kettle, mix and extrude after high-speed stirring, and arrange several strands of the single wires described in step (1) in parallel , making the outside of the single wire extruded and plasticized to form an insulating outer coating layer;

[0065] (3) Preparation of nano-coating layer: hang the earphone wire prepared in step (2) vertically on the baking rack, then plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com