A time relay socket

A technology of time relay and socket, applied in the direction of base/shell, fixed/insulated contact member, etc., can solve the problems of difficulty, increase the manufacturing cost of base and base plate, disadvantageous insulation of socket and sleeve, etc., achieve convenient and strict assembly, improve The effect of controlling reliability and improving safety level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

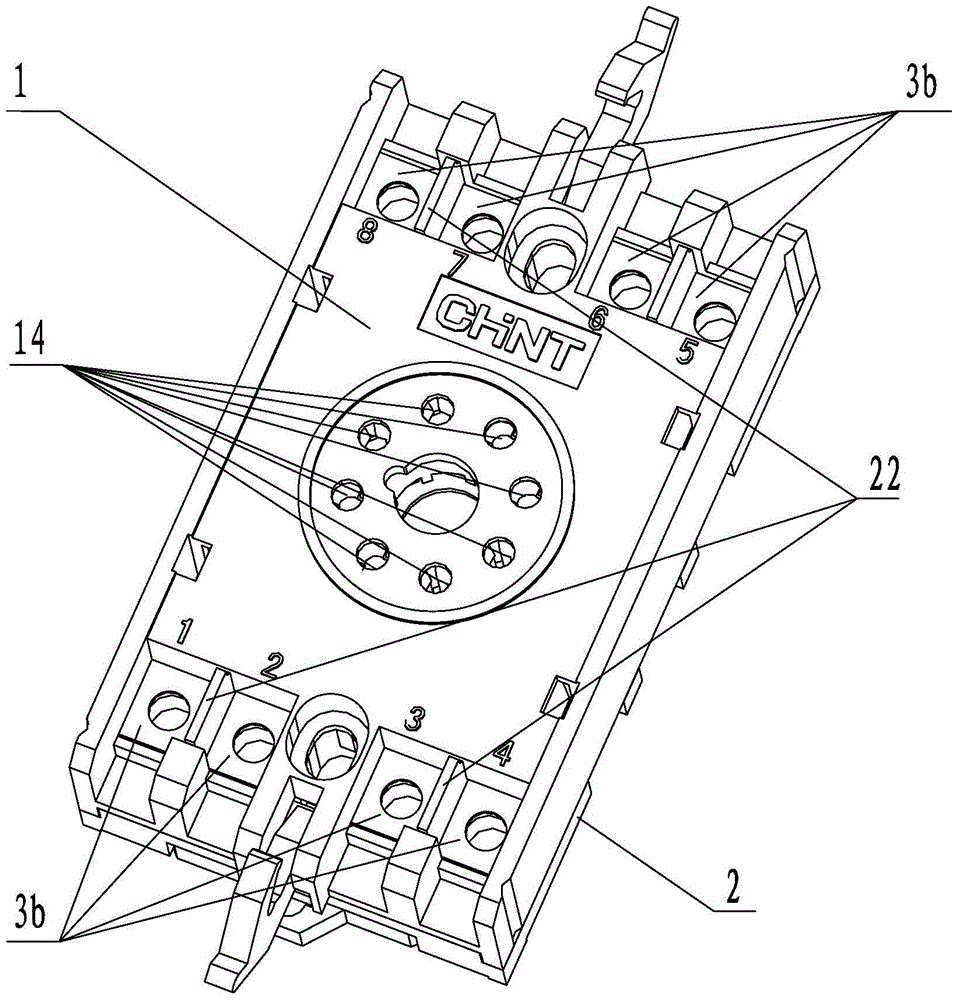

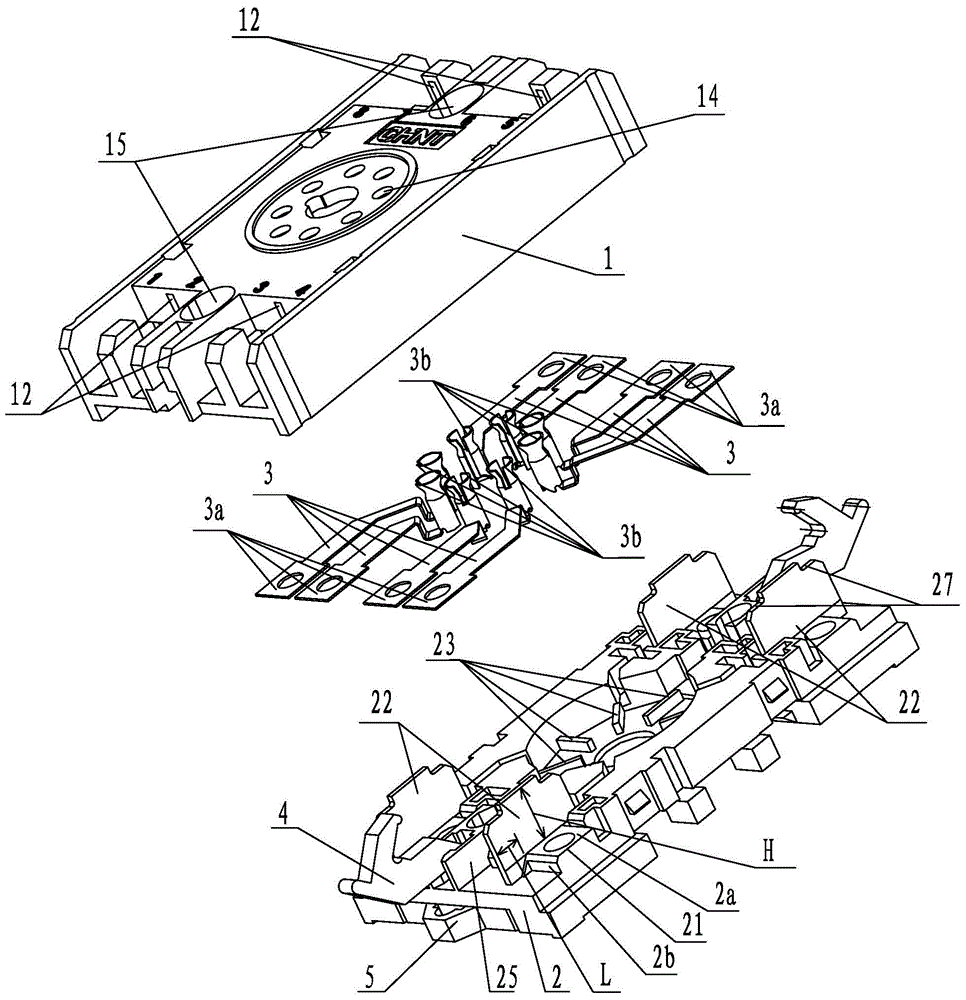

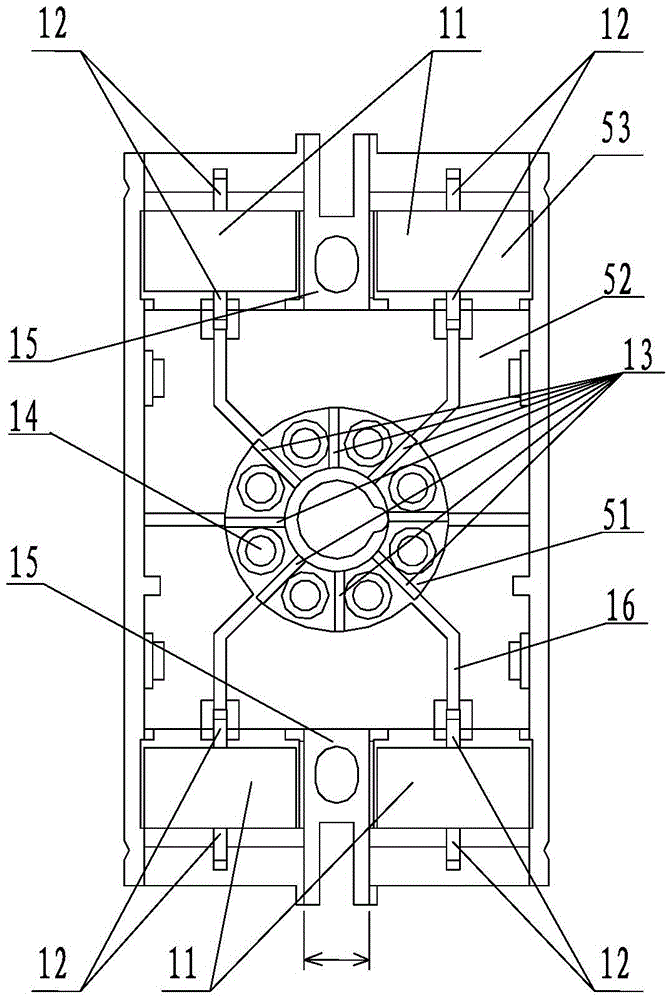

[0021] Combine below Figure 1 to Figure 4 The given examples further illustrate the specific implementation of the time relay socket of the present invention. The time relay socket of the present invention is not limited to the description of the following embodiments.

[0022] see Figure 1 to Figure 4 , The time relay socket of the present invention includes a shell 1, a cover plate 2 and eight conductive sheets 3. The housing 1 is provided with eight jacks 14 for plugs (not shown in the figure) to be inserted into. The conductive sheet 3 adopts a known structure, one end of which is a terminal 3a for connecting a wire (not shown), and the other end is a socket end for connecting a pin of a plug (not shown) 3b. Each socket end 3b of the eight conductive strips 3 is arranged facing the eight jacks 14 respectively, so that each pin of the plug is inserted into the opposite socket end 3b from the eight jacks 14 respectively, and is connected with the socket end. 3b to ach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com