Method of realizing slow rise and slow drop control on laser output power

An output power and laser technology, which is applied to lasers, laser parts, phonon exciters, etc., can solve the problems of laser processing process influence, laser output power overshoot, influence on the welding quality of laser welding starting and ending positions, etc. Stable factor, effect of steady rise and fall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

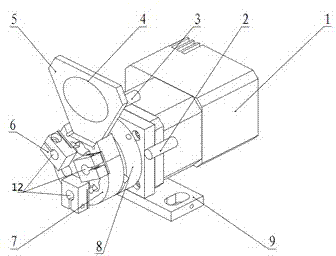

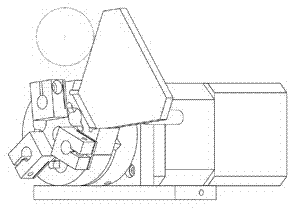

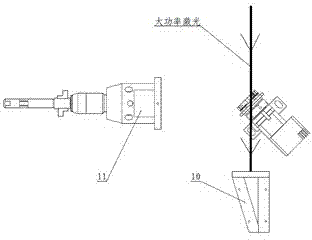

[0017] A method for realizing slow rise and slow down control of laser output power, comprising an optical gate device capable of adjusting and controlling laser energy output, a high-power laser energy absorber 10, and a set of fiber couplers 11, the optical gate device consists of Motor 1, laser reflector 5, fastening stud 6, mirror frame adjustment seat 7, mirror frame mounting base 8 and motor fixing frame 9 are formed, and described mirror frame adjusting seat 7 and mirror frame mounting base 8 are installed on motor ( 1) on the axis, the laser reflector (5) is installed on the mirror frame adjustment seat (7), adjust the mirror frame adjustment seat (7) so that the surface of the laser reflector (5) is perpendicular to the axis, Ensure that the laser reflector (5) moves in one plane when the motor (1) rotates. Control the motor (1) to drive the movement to make the laser reflector 5 change from position 1 ( figure 1 not blocking light) to position 2 ( image 3 complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com