Self-propelled floor cleaning machine and a filter system module

A system module and cleaning machine technology, applied in cleaning machinery, manual floor scrubbing machinery, cleaning equipment, etc., can solve the problem of filter efficiency decline and achieve the effect of optimizing the suction channel guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

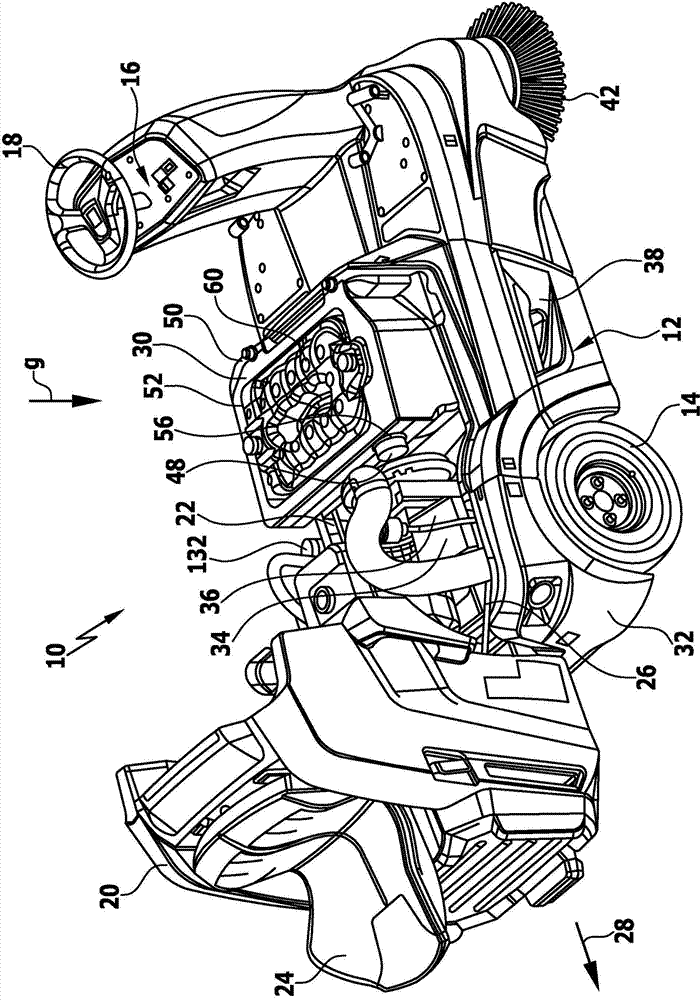

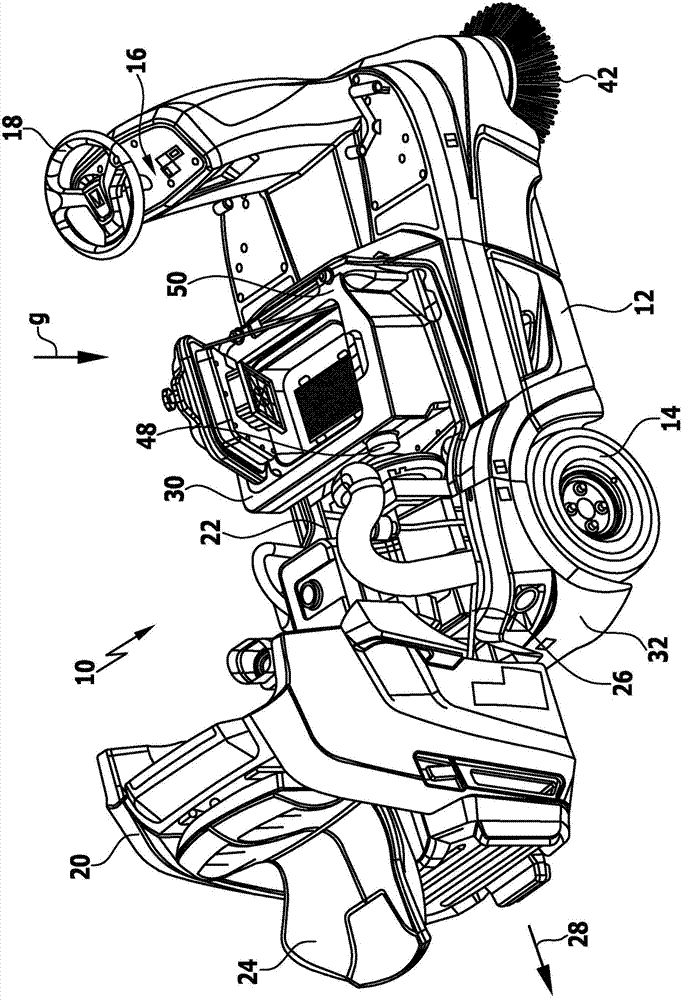

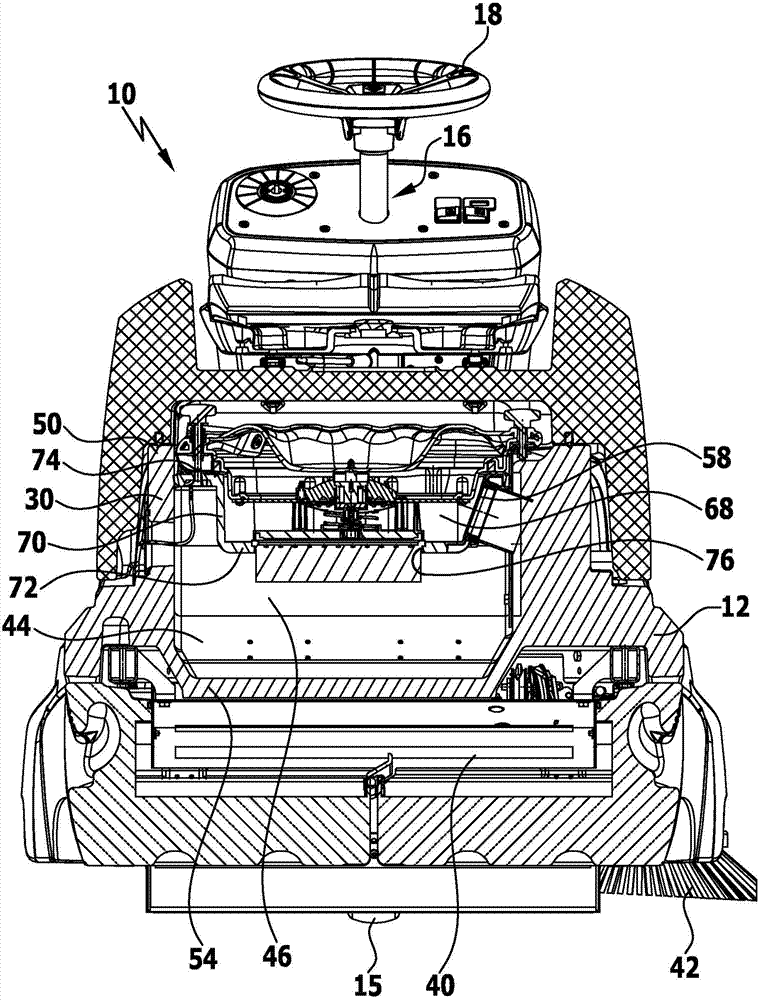

[0054] An embodiment of the self-propelled floor-cleaning machine according to the invention is a sweeper, which is Figure 1 to Figure 3 is shown as a whole and is here denoted by 10 . The sweeper 10 has a chassis 12 . A rear wheel arrangement 14 and a front wheel arrangement 15 are arranged on the chassis 12 . The front wheel arrangement 15 includes one or more front wheels. One or more front wheels can be steered by a steering device 16 with a steering wheel 18 .

[0055] A cover 20 (housing cover) is arranged on the chassis 12 and covers the motor compartment 22 .

[0056] A driver's seat 24 is arranged on the cover 20 .

[0057] In an embodiment, the cover 20 is pivotally retained on the chassis 12 . A corresponding articulation device 26 is arranged in the region of the rear wheel arrangement 14 . Via this hinge, the cover 20 can be lifted in direction 28 in order to gain access to the motor compartment 22 . Furthermore, access to the receptacle 30 for the filter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com