Industrial robot

A technology of industrial robots and robots, applied in the directions of manipulators, manufacturing tools, claw arms, etc., can solve the problems of larger cable guiding space and worse appearance, and achieve the effect of less retention and less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

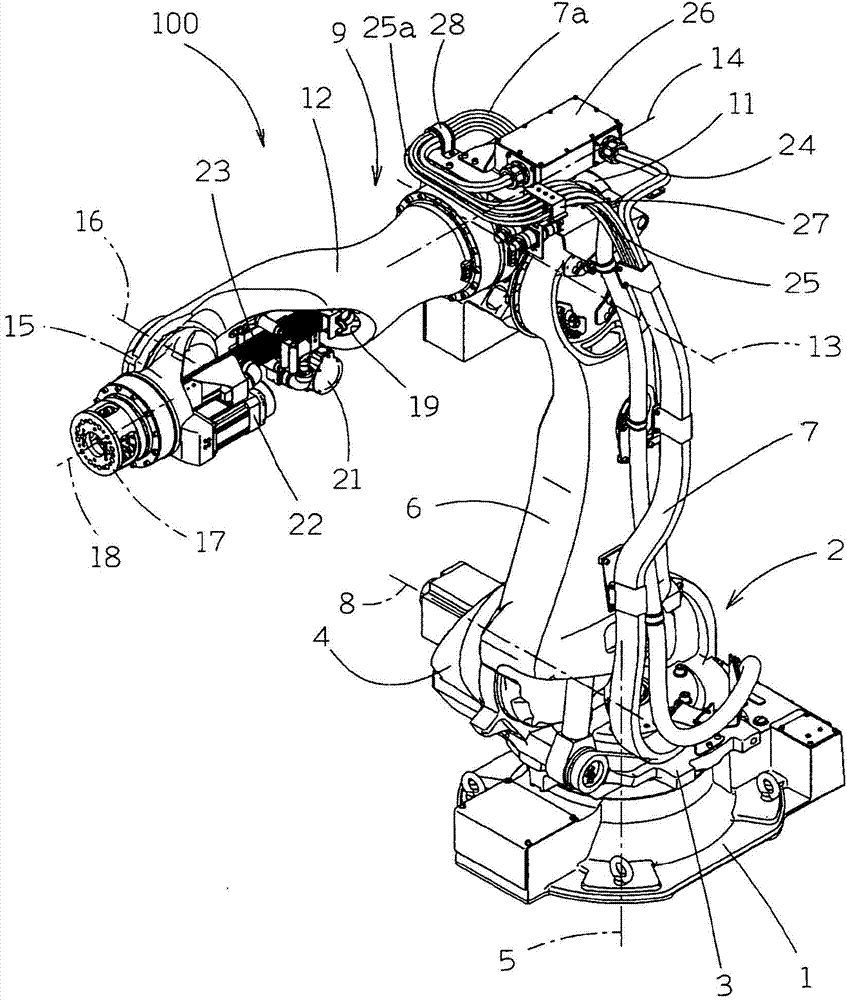

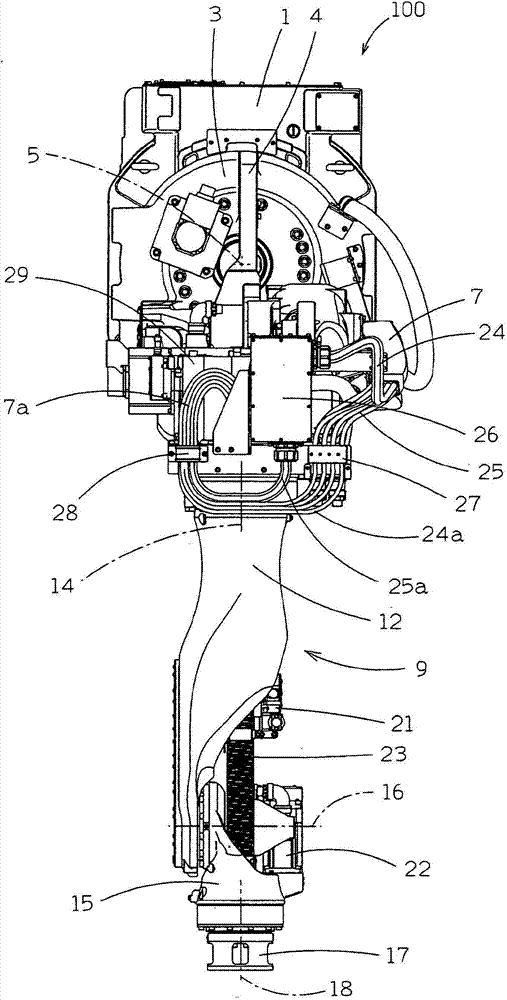

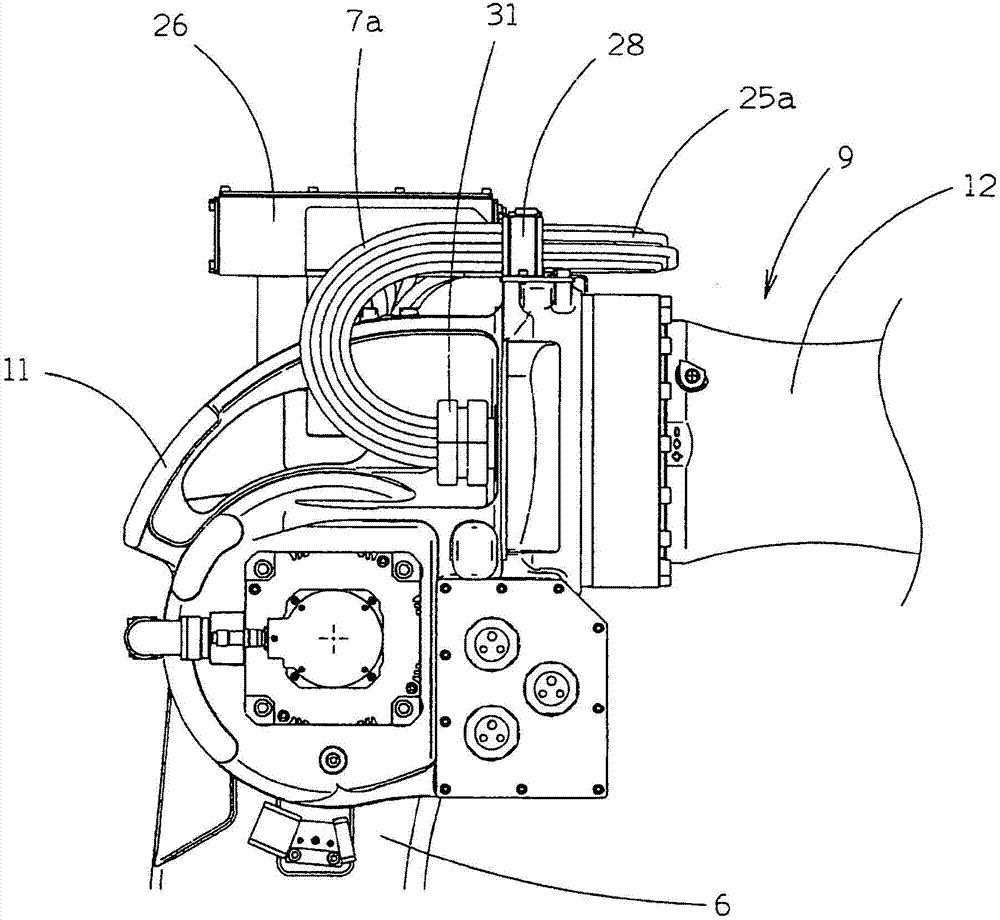

[0030] Next, embodiments of the present invention will be described with reference to the drawings. First, an overall configuration of an industrial robot 100 (welding robot) showing an embodiment of the present invention will be described. like figure 1 and figure 2 As shown, for example, a rack 2 is placed on a base 1 installed on an installation surface such as a floor surface. The frame 2 has a base plate 3 arranged on the upper surface of the base 1 , and a stand plate 4 standing up from the base plate 3 . In addition, a motor (not shown) for rotating the entire rack 2 in a horizontal plane (in a plane parallel to the floor surface) is attached to the upper surface of the base plate portion 3 .

[0031] By rotating the motor shaft of the motor in a predetermined direction, the frame 2 rotates around the first rotation axis 5 provided perpendicular to the floor surface.

[0032] The lower end portion of the lower arm 6 is mounted on the vertical plate portion 4 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com