End wall structure of railway vehicle and processing method of end wall structure

A rail vehicle and processing method technology, applied to the railway car body, railway car body parts, transportation and packaging, etc., can solve the problem of limited impact speed, etc., and achieve the effects of improving impact resistance, ensuring safety, and saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

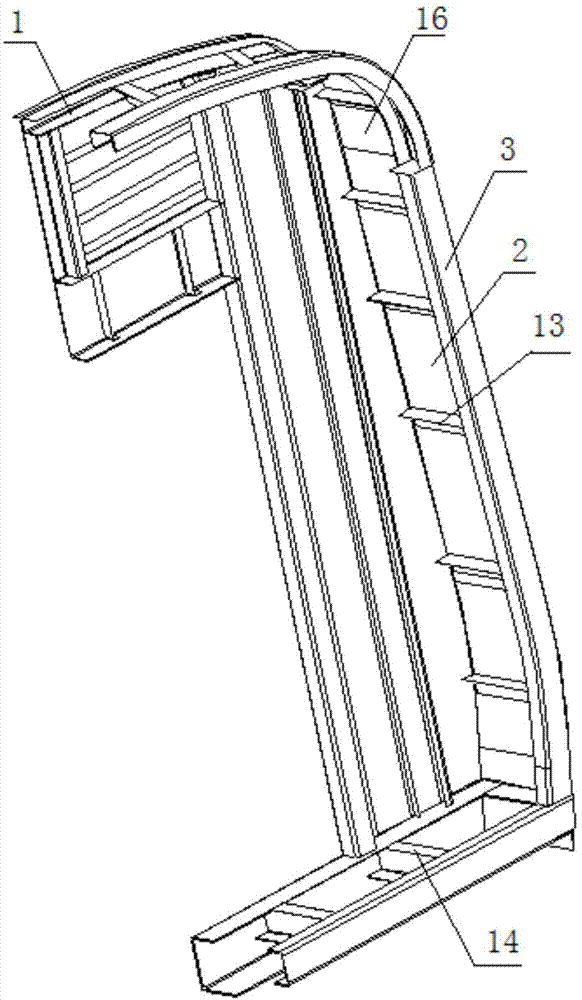

[0040] Such as figure 1 As shown, an end wall structure of a rail vehicle includes a front end wall 1, an energy absorbing component 2, and a rear end frame 3, and the front end wall 1 and the rear end frame 3 are fixedly connected to the energy absorbing component 2 on both sides of the energy absorbing component 2 .

[0041] Such as figure 2 and Figure 5 As shown, the front wall 1 includes the door column 4, the end corner column 5, the door beam 6, the end top curved beam 7, the end wall panel 8, the buffer beam 9, the end top curved beam 7 and the top of the door column 4 and the end corner column 5 Fixedly connected, the two ends of the crossbeam 6 on the door are fixedly connected with the door columns 4 on both sides, and the buffer beam 9 is fixedly connected with the bottoms of the door columns 4 and the end corner columns 5, thus forming a closed front frame.

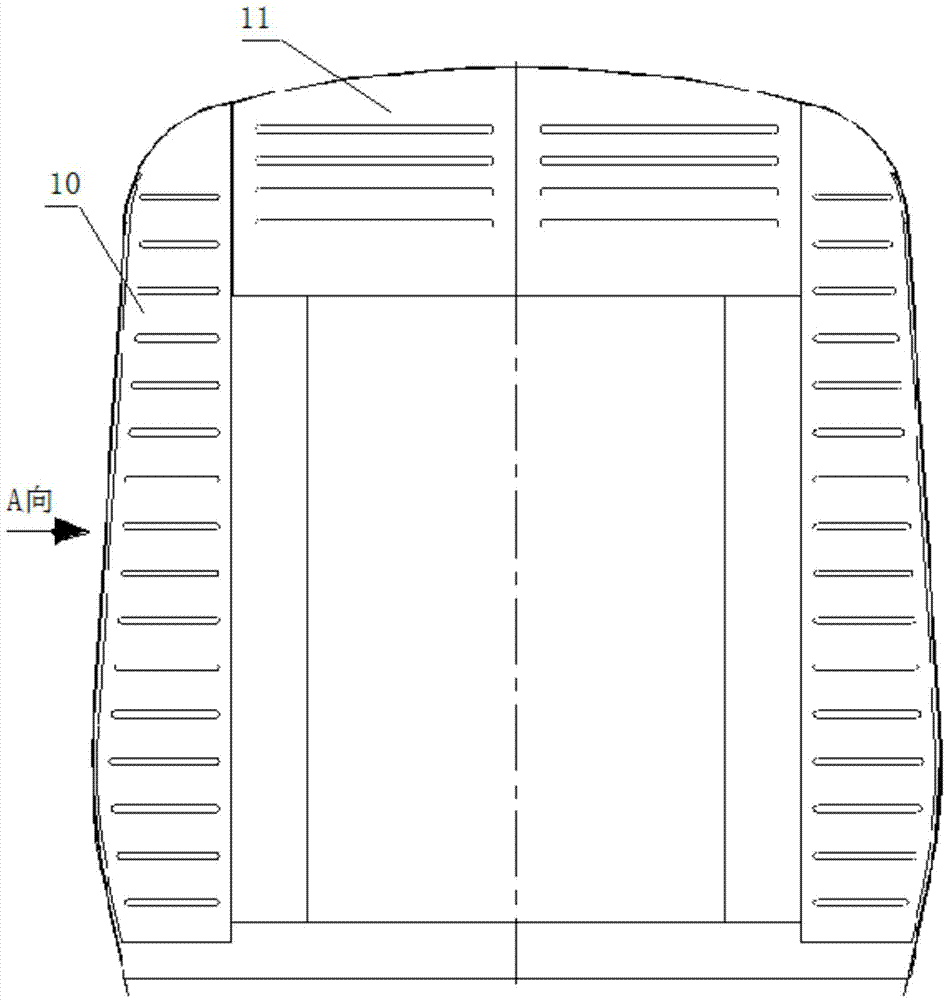

[0042] The end wall panel 8 is composed of an upper end wall panel 11 and a lower end wall panel 10, t...

Embodiment 2

[0074] The installation method of step b in the processing method of the end wall structure in the first embodiment is as follows:

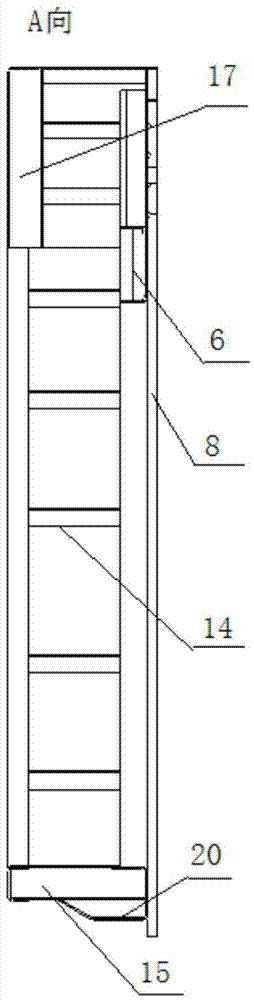

[0075] First connect several skins 16 into a whole by arc welding or adopt a long skin, and then calculate and determine the position where the support needs to be positioned on the skin 16 and the connection position of the energy-absorbing component 2 and the side beam 20 with the skin 16 , and then the skin 16 is fixed into a roughly box-shaped structure by tooling equipment (not shown in the figure), the shape and size of the cross-section of the box-shaped structure are adapted to the cross-section of the rear end frame 3, and the skin 16 at the joint is passed through Arc welding connection, the bottom longitudinal beam 15 and the side beam 20 are connected by arc welding, and then each longitudinal beam and side beam 20 in the energy-absorbing part 2 are respectively connected with the skin 16 according to the predetermined position by resi...

Embodiment 3

[0078] The installation method of step b in the processing method of the end wall structure in the first embodiment is as follows:

[0079] Connect the bottom longitudinal beam 15 and the side beam 20 in the energy-absorbing component 2 by arc welding, connect each longitudinal beam and side beam 20 with the front frame and the rear end frame 3 by arc welding, and then connect the skin 16 with the longitudinal beam and The side beams 20 are connected by resistance spot welding, the longitudinal beams are arranged in parallel longitudinally, and then the two sides of the skin 16 and the front frame and the rear frame 3 are connected by resistance spot welding to form an end wall structure.

[0080] The processing methods and structures of other end wall structures are the same as those in Embodiment 1, and will not be repeated in this embodiment.

[0081] The end wall structure of this rail vehicle uses the modular theory to divide the end wall structure into three parts: the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com