Preparation method of high-intensity polyester fiber cord thread

A technology of high-strength polyester fiber and polyester fiber, which is applied in the field of ropes, can solve the problems of low strength of the cord and cannot meet the normal use of the cord, and achieve the effects of good heat resistance, high strength and good dimensional stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

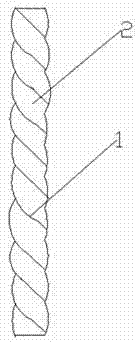

Image

Examples

preparation example Construction

[0013] A preparation method of a high-strength polyester fiber cord is realized through the following steps:

[0014] 1) Material selection: use polyester fiber filament after surface treatment, and its specification is 420D-1000D; the surface treatment process of polyester fiber is as follows: the polyester fiber is subjected to low temperature and atmospheric pressure plasma surface treatment for 20 to 35 minutes, and then sprayed Coupling agent dispersion, after the solvent is volatilized for 100 to 125 minutes, it can be subjected to low temperature and atmospheric pressure plasma surface treatment again for 13 to 15 minutes to obtain high-strength polyester fiber filaments after treatment;

[0015] 2) Doubling: 5-8 polyester filaments are used for doubling and 1 strand;

[0016] 3) Twisting: After paralleling, polyester fiber filaments are twisted through a twisting machine, and the transmission belt of the twisting machine is tight and tight. Each filament must be contro...

Embodiment 1

[0020] 1) Material selection: use polyester fiber filament after surface treatment, and its specification is 420D;

[0021] 2) Doubling: 6 polyester filaments are used for doubling and 1 strand;

[0022] 3) Twisting: The paralleled polyester filaments are twisted through a twisting machine, and the transmission belt of the twisting machine is tight and tight. Each filament must be controlled by a tension regulator, and its speed and twist are measured regularly. The twist is based on Depending on the size of the strands, generally less than 20 twists / m;

[0023] 4) Heat setting: heat setting the twisted polyester filaments through a steam setting machine at a temperature of 60°C and a pressure of 0.05Mpa for 30 minutes to obtain a strand 1;

[0024] 5) Forming: 3 heat-set polyester fiber strands 1 are twisted and formed by a rope twisting machine with a twist of 60 twists / m to obtain a high-strength polyester fiber cord that meets the requirements.

Embodiment 2

[0026] 1) Material selection: use polyester fiber filament after surface treatment, and its specification is 630D;

[0027] 2) Doubling: 7 polyester filaments are used for doubling and 1 strand;

[0028] 3) Twisting: The paralleled polyester filaments are twisted through a twisting machine, and the transmission belt of the twisting machine is tight and tight. Each filament must be controlled by a tension regulator, and its speed and twist are measured regularly. The twist is based on Depending on the size of the strands, generally less than 20 twists / m;

[0029] 4) Heat setting: heat setting the twisted polyester filaments through a steam setting machine at a temperature of 70°C and a pressure of 0.06Mpa for 50 minutes to obtain a strand 1;

[0030] 5) Forming: 9 heat-set polyester fiber strands 1 are twisted and formed by a rope twisting machine with a twist of 100 twists / m to obtain a high-strength polyester fiber cord that meets the requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com