Gas turbine with cooling air cooling system and method for operation of gas turbine at low part load

A technology for cooling air and gas turbines, applied in gas turbine installations, charging systems, engine cooling, etc., can solve problems such as harmful compressor efficiency, and achieve the effects of reducing energy consumption, simple structure, and satisfying emission adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

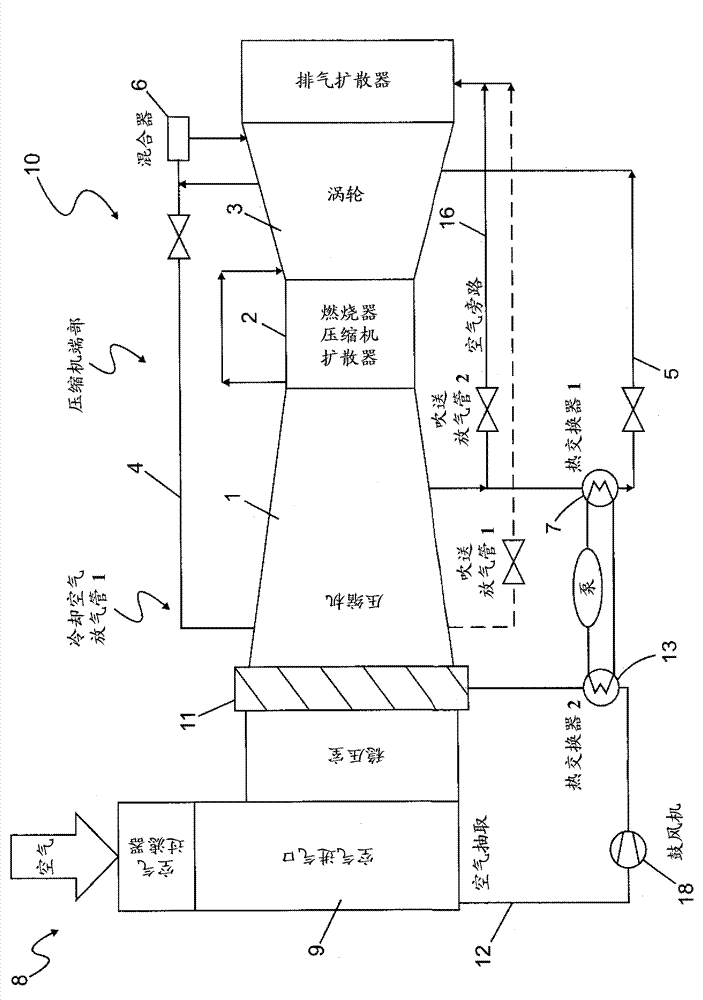

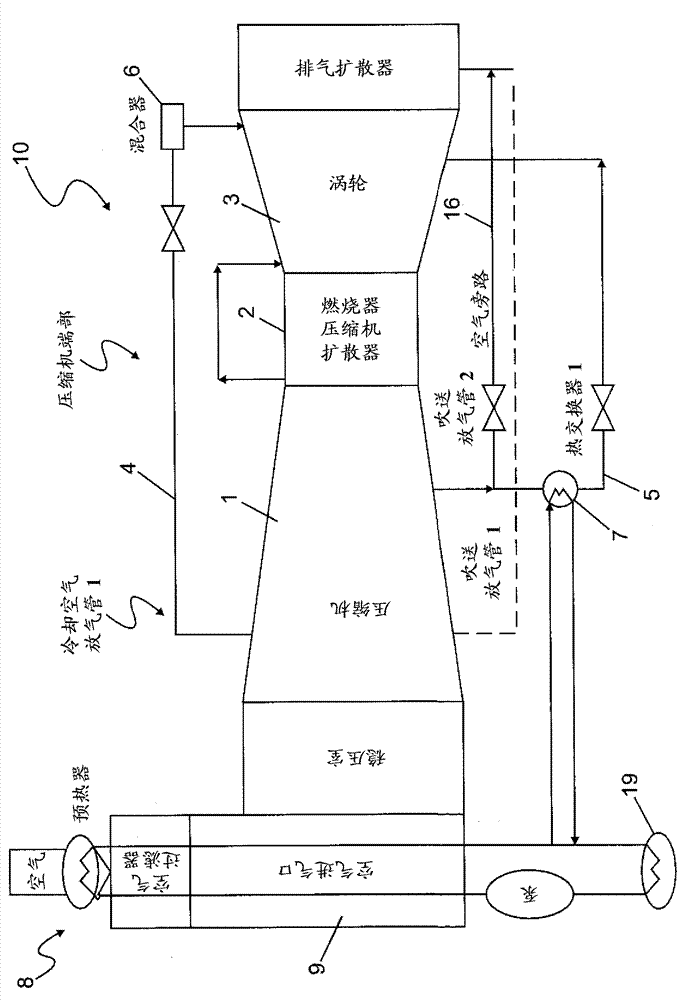

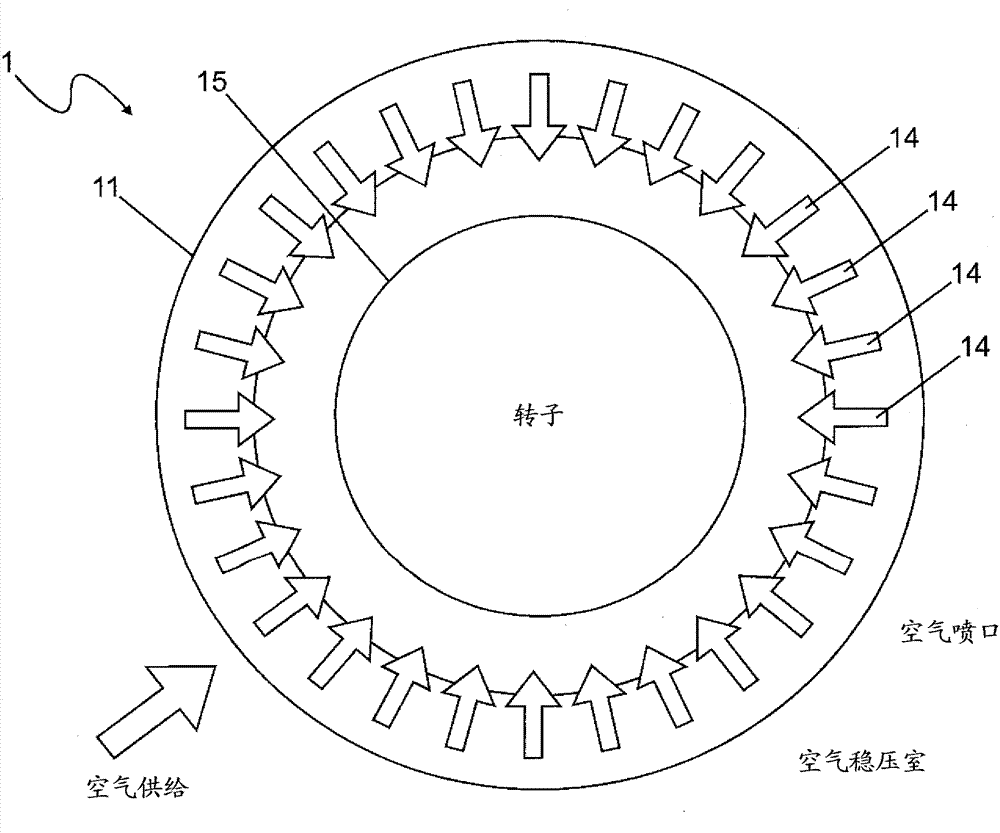

[0026] figure 1 A schematic diagram of a first embodiment of a gas turbine according to the invention is shown with a cooling air cooling system for the inlet air to the compressor 1 and a preheater system 8 . The gas turbine 10 basically includes a compressor 1 , a combustor 2 and a turbine 3 . The gas turbine 10 is also provided in this embodiment with a preheater system 8 upstream of the air inlet 9 , whereby the inlet air flowing to the compressor 1 is heated, especially in part-load operation of the gas turbine 10 . Due to having at least a first cooling air line 4 or a cooling air bleeder pipe at the first pressure level of the compressor 1 and at least one second cooling air line 5 at a position downstream of the compressor 1 with respect to the first cooling air line 4 , the cooling air cooling system of the gas turbine 10 is particularly suitable for part-load operation, ie for cooling air that initially has a higher temperature and pressure. Cooling air from the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com